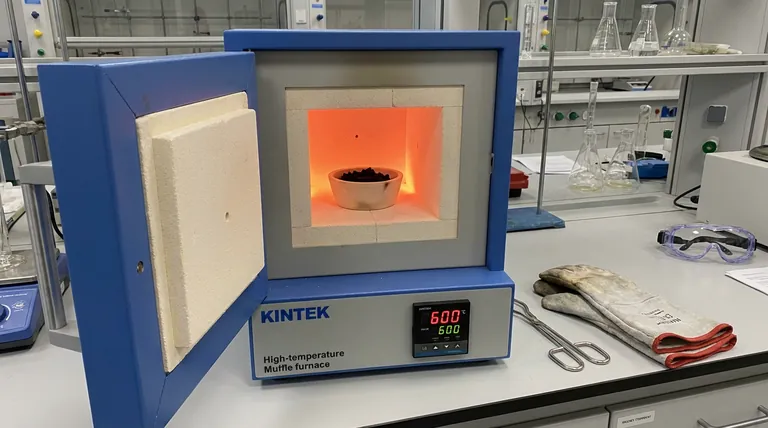

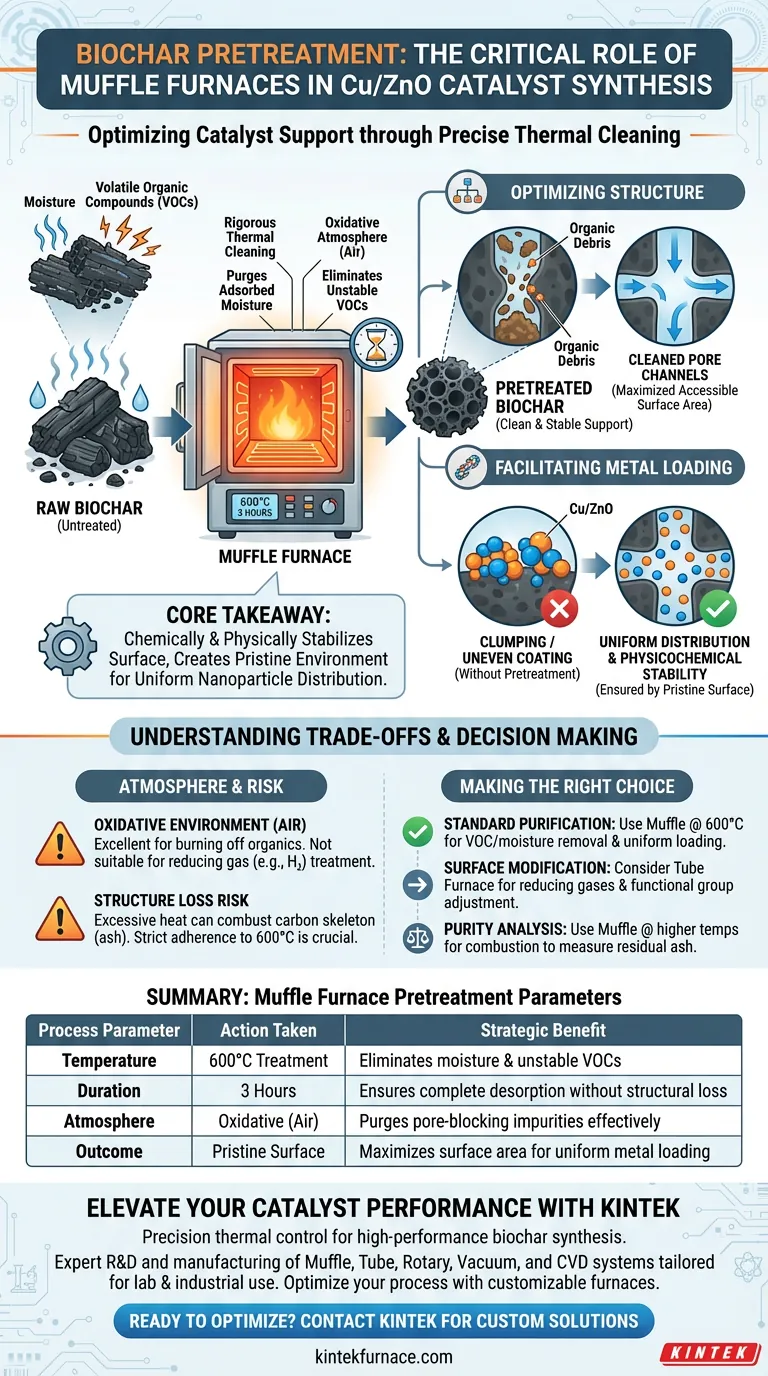

The primary purpose of using a Muffle furnace for biochar pretreatment is to subject the material to a rigorous thermal cleaning process, specifically heating it at 600°C for 3 hours. This step is critical to eliminate adsorbed moisture and unstable volatile organic compounds (VOCs) that naturally adhere to the biochar surface. By removing these impurities, the furnace prepares the carbon structure to act as an effective catalyst support.

Core Takeaway The Muffle furnace does not just dry the biochar; it chemically and physically stabilizes the surface by purging pore-blocking impurities. This creates a pristine environment that allows for the uniform distribution of Cu/ZnO nanoparticles, which is the defining factor in the final catalyst's performance.

Optimizing the Biochar Support Structure

Removing Volatile Obstacles

Biochar typically retains moisture and various unstable organic compounds within its structure. The Muffle furnace provides a consistent, high-temperature environment that forces these components to desorption and decompose.

Cleaning the Pore Channels

The effectiveness of a catalyst support relies on its surface area. The thermal treatment effectively "cleans" the pore structures of the biochar.

By clearing these channels of organic debris, the total accessible surface area for the metal catalyst is maximized.

Facilitating Metal Nanoparticle Loading

Ensuring Uniform Distribution

Once the biochar is pretreated, it must serve as a host for metal active components—in this case, Cu/ZnO. The removal of impurities prevents physical blockages that could lead to clumping or uneven coating.

A clean surface ensures that the metal nanoparticles can penetrate deep into the pores and load uniformly across the carrier.

Establishing Physicochemical Stability

The Muffle furnace creates a stable physicochemical environment. This stability is vital because it ensures that the biochar interacts predictably with the metal precursors during the subsequent synthesis steps.

Without this stabilization, residual volatiles could react with the metal precursors, potentially altering the chemical nature of the active sites or weakening the interaction between the support and the metal.

Understanding the Trade-offs

Atmosphere Limitations

A standard Muffle furnace typically operates in an air environment, making it an oxidative treatment. While excellent for burning off organics and moisture, it lacks the atmosphere control of a tube furnace.

If your process requires the specific removal of oxygen-containing functional groups using reducing gases (like hydrogen), a Muffle furnace is not suitable; a tube furnace would be required to control the gas flow and prevent total combustion.

Risk of Structure Loss

While 600°C is the specified target for this process, excessive temperatures or duration in an oxidative environment can lead to the combustion of the carbon skeleton itself (turning it to ash).

Precise adherence to the 600°C for 3 hours protocol is essential to clean the biochar without degrading its structural integrity.

Making the Right Choice for Your Goal

To ensure you are applying the correct thermal treatment for your specific catalyst requirements, consider the following:

- If your primary focus is standard purification: Use a Muffle furnace at 600°C to remove VOCs and moisture to ensure uniform metal loading.

- If your primary focus is surface chemistry modification: Consider a tube furnace to introduce reducing gases for the gradient adjustment of functional groups.

- If your primary focus is purity analysis: Use the Muffle furnace at higher temperatures to fully combust the carbon and measure residual ash content to evaluate mineral impurities.

The success of your Cu/ZnO catalyst relies not just on the metals used, but on the pristine condition of the biochar foundation prepared by the furnace.

Summary Table:

| Process Parameter | Action Taken | Strategic Benefit |

|---|---|---|

| Temperature | 600°C Treatment | Eliminates moisture and unstable VOCs |

| Duration | 3 Hours | Ensures complete desorption without structural loss |

| Atmosphere | Oxidative (Air) | Purges pore-blocking impurities effectively |

| Outcome | Pristine Surface | Maximizes surface area for uniform metal loading |

Elevate Your Catalyst Performance with KINTEK

Precision is the foundation of high-performance biochar synthesis. At KINTEK, we understand that your research demands rigorous thermal control to achieve uniform nanoparticle distribution. Backed by expert R&D and manufacturing, we provide high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for lab-scale and industrial applications.

Whether you need standard purification or specialized atmospheric control for surface chemistry modification, our customizable high-temperature furnaces are engineered to meet your unique materials science needs.

Ready to optimize your synthesis process? Contact KINTEK today to discuss your custom furnace solution!

Visual Guide

References

- Seyed Alireza Vali, Antoni Sánchez. Biochar-supported highly dispersed ultrasmall Cu/ZnO nanoparticles as a highly efficient novel catalyst for CO2 hydrogenation to methanol. DOI: 10.18331/brj2025.12.2.3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a high-temperature muffle furnace required for the secondary calcination of SC-NMNO? Key to Single Crystals

- What key components are used in vacuum muffle furnaces to ensure precise gas dispersion? Discover the MFC and BPR System

- What role does the Muffle Furnace play in the pretreatment of K-Mo catalyst precursors? Key for Thermal Oxidation

- What are the main functions of muffle furnaces in materials processing? Achieve Precise, Clean Thermal Control for Your Lab

- What are the primary heat transfer mechanisms in a box furnace? Master Radiation and Convection for Optimal Heating

- What are the controller-based classifications of muffle furnaces? Choose the Right Control for Your Lab

- What is the most common format for Controlled Atmosphere Continuous Muffle Furnaces? Belt Furnace for High-Throughput Processing

- What role does a laboratory oven play in determining the porosity of FOPC? Ensuring Precision in Material Density