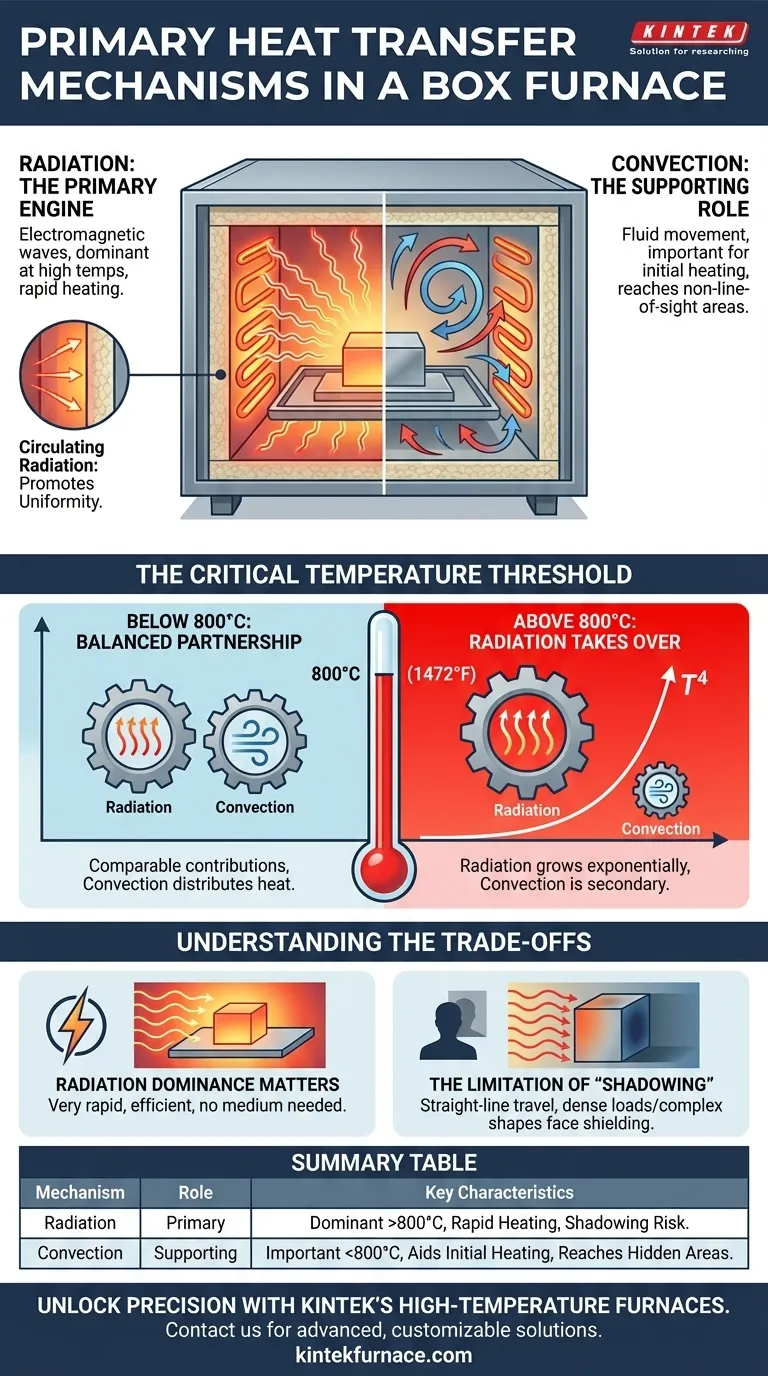

In a box furnace, the primary heat transfer mechanisms are radiation and convection. While both are always present, their significance changes dramatically with temperature. At the high temperatures typical for these furnaces, radiation is the dominant and most critical mode of heat transfer, with convection playing a more supportive role, especially during the initial heat-up phase.

The key to mastering a box furnace is not just knowing that radiation and convection occur, but understanding that their balance shifts. Above approximately 800°C, radiation becomes the overwhelming force, a principle that dictates everything from heating speed to temperature uniformity.

The Two Pillars of Heat Transfer

A box furnace heats a workpiece by moving thermal energy from its heating elements to the material inside. This energy transfer relies on two distinct physical principles working in tandem.

Radiation: The Primary Engine

Radiation is the transfer of energy through electromagnetic waves. In a furnace, the electric heating elements and hot gases glow, emitting thermal radiation in all directions.

This energy travels through the furnace atmosphere and strikes the workpiece and the internal furnace walls. The walls, in turn, absorb this energy, heat up, and become secondary radiators, bouncing and re-emitting thermal energy. This phenomenon, known as circulating radiation, is crucial for achieving a uniform temperature.

Convection: The Supporting Role

Convection is heat transfer through the movement of a fluid—in this case, the air or atmosphere inside the furnace. As the gas near the heating elements gets hot, it becomes less dense and rises.

This movement creates a natural circulation pattern, or convective current, that transfers heat as the hot gas flows over the surface of the workpiece. While less powerful than radiation at high temperatures, it is important for initial heating and reaching parts of a workpiece that may not have a direct line of sight to the heating elements.

The Critical Temperature Threshold

The effectiveness of these two mechanisms is not static; it is highly dependent on the furnace's operating temperature. The relationship between them defines the furnace's heating characteristics.

Below 800°C: A Balanced Partnership

At lower temperatures, typically below 800°C (1472°F), the contributions of convection and radiation are more comparable.

During this initial heating stage, the convective currents play a significant role in distributing heat throughout the chamber and bringing the workpiece up to temperature.

Above 800°C: Radiation Takes Over

The power of radiative heat transfer increases with the fourth power of temperature (T⁴). This means its effect grows exponentially as the furnace gets hotter.

Once the furnace temperature exceeds approximately 800°C, the impact of radiation becomes dramatically more significant than convection. At the highest operating temperatures, nearly all effective heat transfer is accomplished through radiation from the elements and the hot furnace walls.

Understanding the Trade-offs

The dominance of radiation has direct consequences for how you should use a box furnace to achieve consistent results.

Why Radiation Dominance Matters

A radiation-dominant environment allows for very rapid and efficient heating at high temperatures. Because the energy is delivered via line-of-sight electromagnetic waves, it does not rely on a medium like air to transfer heat.

The Limitation of "Shadowing"

The primary drawback of radiation is that it travels in straight lines. If you have a densely packed load or a part with a very complex geometry, some surfaces may be shielded from the direct radiation of the heating elements or hot walls.

These "shadowed" areas will heat more slowly, relying on secondary radiation and weaker convection, which can lead to non-uniform heating and internal stresses in the material.

The Role of Furnace Components

The design of the furnace directly supports these mechanisms. The heating elements are the primary radiation source. The insulated furnace walls (cabinet) are designed to withstand high heat and have high emissivity, allowing them to effectively absorb and re-radiate energy to promote uniformity. The temperature control system precisely manages the energy output to control this entire radiative environment.

Making the Right Choice for Your Goal

By understanding this interplay, you can operate a box furnace more effectively and troubleshoot heating issues.

- If your primary focus is rapid, high-temperature processing: You will operate in a radiation-dominant regime. Focus on workpiece placement to ensure all critical surfaces have a clear line of sight to the heating elements or hot walls.

- If your primary focus is uniform heating of complex parts: Mitigate shadowing by allowing more space between parts. Consider longer soak times at temperature to allow heat to conduct through the material and even out any differences caused by non-uniform radiation.

- If your primary focus is energy efficiency: Acknowledge that the re-radiation from well-insulated walls is a key contributor to efficiency. Ensuring the door seal is tight and the refractory insulation is in good condition is critical to minimizing heat loss.

Mastering your heating process begins with a clear understanding of the fundamental physics at work inside the furnace.

Summary Table:

| Mechanism | Role | Key Characteristics |

|---|---|---|

| Radiation | Primary | Dominant above 800°C, transfers energy via electromagnetic waves, enables rapid heating, but can cause shadowing in complex geometries. |

| Convection | Supporting | Important below 800°C, transfers heat through fluid movement (e.g., air), aids in initial heating and reaching non-line-of-sight areas. |

Unlock Precision in Your Lab with KINTEK's High-Temperature Furnaces

Struggling with non-uniform heating or slow processing times in your experiments? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to optimize heat transfer mechanisms like radiation and convection for superior performance. With strong deep customization capabilities, we precisely meet your unique experimental requirements, ensuring energy efficiency, rapid heating, and consistent results.

Contact us today via our contact form to discuss how our furnaces can enhance your research and production processes!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts