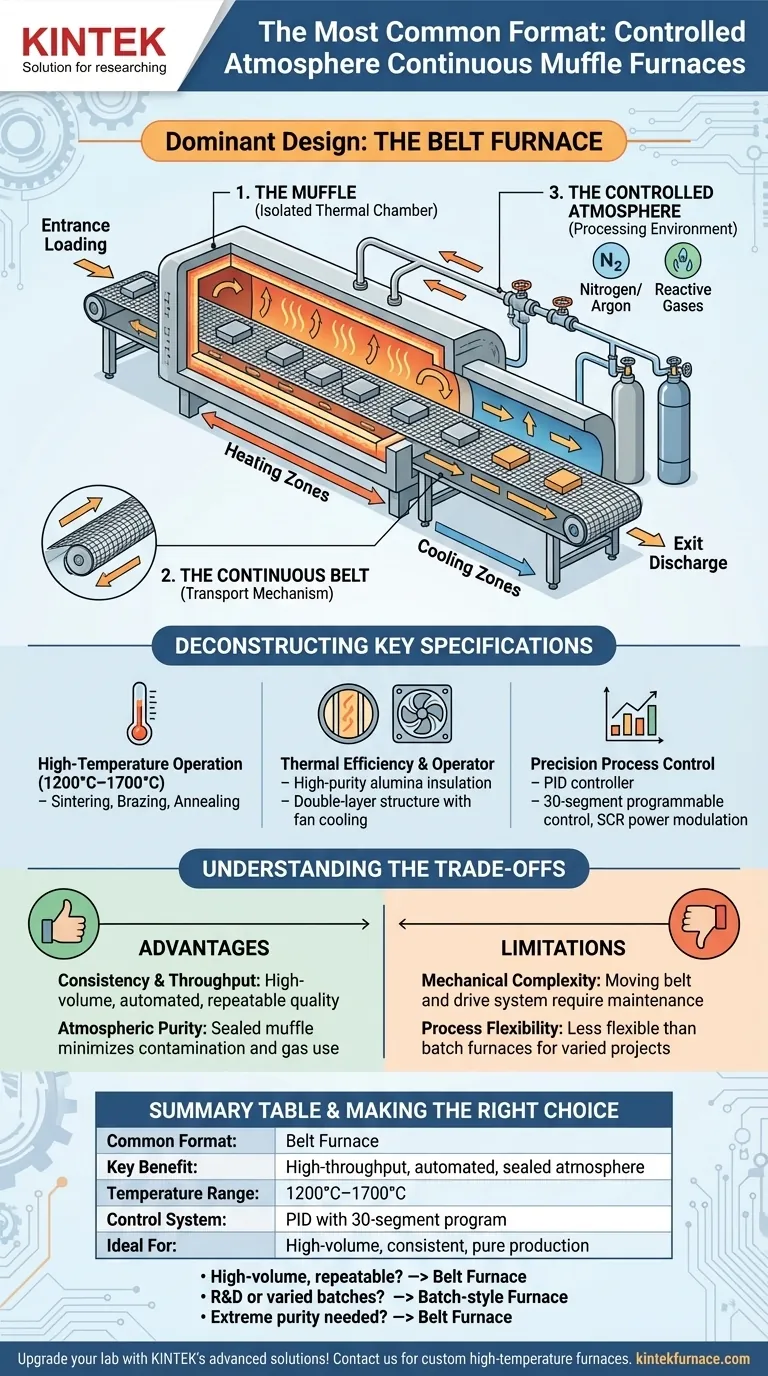

For Controlled Atmosphere Continuous Muffle Furnaces, the most common and dominant design is the belt furnace. This format uses a continuously moving mesh belt, typically made of a high-temperature metal alloy or ceramic, to transport products through a sealed chamber known as a muffle. This design is the industry standard for processes requiring consistent, high-throughput thermal processing in a precisely managed atmosphere.

The core reason for the belt furnace's prevalence is its ability to combine high-volume, automated production with the strict atmospheric control of a sealed muffle. This makes it an ideal solution for manufacturing processes where both consistency and purity are non-negotiable.

How a Continuous Muffle Belt Furnace Works

Understanding the function of a belt furnace requires looking at its three primary systems: the muffle, the continuous belt, and the atmosphere control. These elements work in concert to create a stable and repeatable thermal processing environment.

The Muffle: An Isolated Thermal Chamber

A muffle is a sealed, separated retort or chamber within the furnace's insulated body. Its primary job is to isolate the product and its surrounding atmosphere from the heating elements and outside air.

This isolation is critical for preventing contamination and allowing for the precise management of the internal gas composition.

The Continuous Belt: The Transport Mechanism

The "continuous" aspect is achieved via a conveyor belt that runs the entire length of the furnace. Products are loaded at the entrance, travel through various heating and cooling zones on the belt, and are discharged at the exit.

These belts are engineered from advanced metal alloys or ceramics to withstand extreme temperatures and the chemical environment inside the muffle.

The Controlled Atmosphere: The Processing Environment

A "controlled atmosphere" refers to the carefully regulated mixture of gases intentionally introduced into the muffle. This can range from inert gases like nitrogen or argon to prevent oxidation, to active gases that facilitate specific chemical reactions like carburizing or nitriding.

The sealed muffle design is exceptionally effective at maintaining the purity of this atmosphere and minimizing gas consumption.

Deconstructing Key Specifications

The capabilities of these furnaces are defined by a standard set of technical specifications. Understanding what they mean reveals the furnace's true operational potential.

High-Temperature Operation (1200°C–1700°C)

This temperature range is a key indicator of the furnace's capability. A maximum operating temperature between 1200°C and 1700°C enables advanced processes such as sintering metal powders, brazing complex assemblies, annealing specialty alloys, and firing technical ceramics.

Thermal Efficiency and Operator Safety

Modern furnaces use high-purity fibrous alumina insulation, which offers excellent thermal retention and allows for faster heat-up and cool-down cycles, saving energy.

Simultaneously, a double-layer steel structure with active fan cooling keeps the exterior of the furnace at a safe temperature for operators, a critical feature in any industrial environment.

Precision Process Control

The most critical feature is the control system. A PID (Proportional-Integral-Derivative) controller provides precise temperature management, preventing overshoot and maintaining stability.

This is often paired with 30-segment programmable control, allowing operators to design complex thermal profiles with specific ramp rates, soak times, and cooling stages. Power is modulated via SCRs (Silicon Controlled Rectifiers) to ensure smooth and accurate energy delivery to the heating elements.

Inherent Safety Mechanisms

A standard feature is a safety interlock that automatically cuts power to the heating elements if a door is opened or another fault condition is detected. This is a fundamental requirement for protecting both personnel and the equipment itself.

Understanding the Trade-offs

While dominant, the continuous muffle belt furnace is not the universal solution. Its design comes with a clear set of advantages and limitations.

Advantage: Consistency and Throughput

The continuous, automated nature of a belt furnace is unmatched for high-volume manufacturing. It ensures every part sees the exact same thermal profile, leading to highly consistent and repeatable product quality.

Advantage: Atmospheric Purity

Because the muffle is a fully sealed chamber, it excels at maintaining a pure, low-consumption controlled atmosphere. This is a significant benefit over open-belt or pusher-style furnaces.

Limitation: Mechanical Complexity

The conveyor belt and drive system are moving parts that operate in an extreme environment. They are consumables that will eventually require maintenance and replacement, representing an ongoing operational cost.

Limitation: Process Flexibility

A belt furnace is optimized for a specific process and product size range. It is less flexible than a "batch" furnace for handling one-off R&D projects or a wide variety of part geometries and process recipes.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on your production goals.

- If your primary focus is high-volume, repeatable production: The continuous muffle belt furnace is the definitive choice for its automation, consistency, and process control.

- If your primary focus is R&D or small, highly varied batches: A batch-style muffle furnace will likely offer better operational flexibility for your needs.

- If your primary focus is maintaining extreme atmospheric purity for sensitive materials: The sealed muffle design of a belt furnace provides a distinct advantage over other continuous furnace types.

Understanding these core principles empowers you to select not just a piece of equipment, but the right manufacturing process for your specific goal.

Summary Table:

| Feature | Description |

|---|---|

| Common Format | Belt Furnace |

| Key Benefit | High-throughput, automated production with sealed atmosphere control |

| Temperature Range | 1200°C–1700°C |

| Control System | PID controller with 30-segment programmable control |

| Ideal For | High-volume manufacturing requiring consistency and purity |

| Limitations | Mechanical complexity and less flexibility for varied batches |

Upgrade your lab's thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for consistent, high-throughput results. Contact us today to discuss how our tailored furnace solutions can enhance your efficiency and product quality!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance