In essence, a Split Tube Furnace (Single Zone) serves a specific but critical purpose: it is designed for high-temperature thermal processing where both easy access to the sample and a single, uniform temperature are required. Its hinged "split" design allows operators to quickly place or remove a reaction tube without disturbing the entire setup, making it an ideal workhorse for standardized research experiments, annealing, and material synthesis.

The primary value of a Split Tube Furnace is its combination of operational convenience and thermal uniformity. Its hinged design prioritizes rapid sample access, while its single heating zone ensures consistent temperature, making it a reliable tool for controlled batch processing.

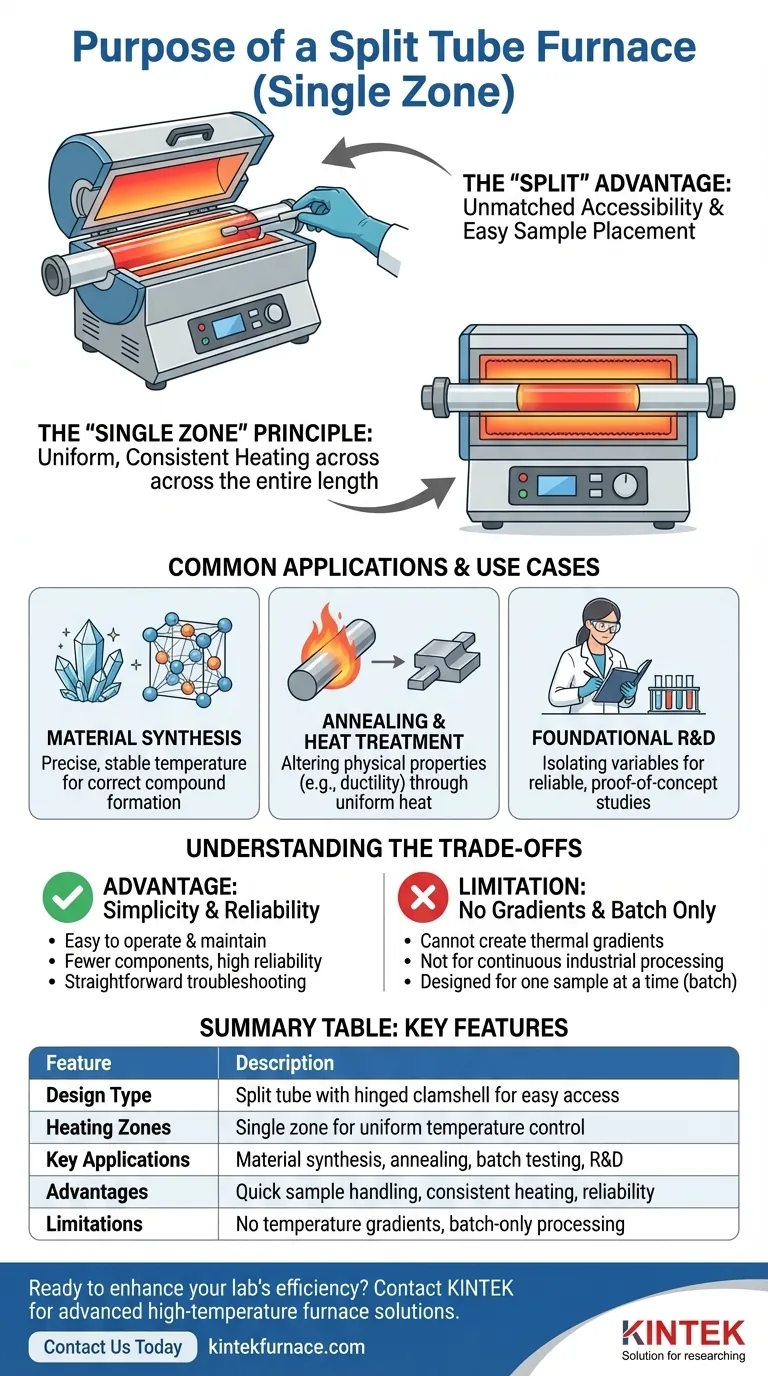

Deconstructing the Design: "Split Tube" and "Single Zone"

To understand its purpose, you must understand its two defining characteristics. The name itself describes exactly how it functions and why it is chosen for specific laboratory tasks.

The "Split" Advantage: Unmatched Accessibility

The "split" feature refers to the furnace body being built on a hinge. This allows it to open like a clamshell.

This design directly facilitates the easy placement and removal of the work tube, which contains the sample. This is especially useful for tubes that are sealed, have complex end-fittings, or are fragile.

By opening the furnace, operators can avoid the risk of damaging the tube or its contents, which can occur when sliding it into a solid, non-splitting furnace. This drastically speeds up the workflow for batch testing.

The "Single Zone" Principle: Uniform Heating

The "single zone" designation means the furnace has one set of heating elements governed by one temperature controller.

The goal is to create a single, highly uniform, and stable thermal environment across the entire heated length of the furnace. The furnace operates on the principle of resistive heating, where electrical energy heats elements that encircle the work tube.

This ensures that the entire sample inside the tube experiences the same temperature, which is critical for achieving consistent and repeatable results in many chemical and materials science processes.

Common Applications and Use Cases

The combination of easy access and uniform heating makes this furnace a versatile tool for a range of applications.

Material Synthesis

Many synthetic processes, such as creating specific crystal structures or chemical compounds, require a precise and stable temperature. The single zone provides the thermal consistency needed to ensure the entire batch of material forms correctly.

Annealing and Heat Treatment

Annealing is a heat treatment process that alters a material's physical properties, typically to increase its ductility and reduce its hardness. This requires heating the material to a specific temperature and holding it there, making the uniform heat of a single-zone furnace essential.

Foundational Research and Development

In R&D, isolating variables is key. The simplicity of a single-zone furnace ensures that temperature is not a confounding variable in an experiment. Its reliability and ease of use make it a staple for foundational studies and proof-of-concept work.

Understanding the Trade-offs

No single piece of equipment is perfect for every task. The Split Tube (Single Zone) furnace has clear advantages but also specific limitations you must consider.

Advantage: Simplicity and Reliability

With only one heating zone and one controller, these furnaces are exceptionally easy to operate and maintain. Fewer components mean fewer potential points of failure, leading to high reliability and straightforward troubleshooting.

Limitation: Inability to Create Temperature Gradients

The primary trade-off is its lack of flexibility for complex thermal profiles. If your process requires different parts of the sample to be held at different temperatures simultaneously—a common requirement in Chemical Vapor Deposition (CVD)—this furnace is the wrong choice. A multi-zone furnace would be necessary.

Limitation: Not Designed for Continuous Processing

This furnace is designed for batch processing, where one sample is processed at a time. It is not suitable for continuous industrial applications where material must constantly flow through the heat source, a task better suited for rotary tube furnaces.

Making the Right Choice for Your Goal

Selecting the correct furnace depends entirely on the requirements of your process.

- If your primary focus is rapid batch testing or annealing: The Split Tube (Single Zone) is ideal due to its easy sample access and uniform heating.

- If your primary focus is creating materials that require different temperature stages simultaneously (e.g., specific types of CVD): You must consider a multi-zone furnace to create the necessary thermal gradient.

- If your primary focus is continuous industrial production: A rotary furnace or other continuous system is a more appropriate choice for high-volume processing.

By understanding its core design principles, you can confidently determine if this furnace's blend of accessibility and uniformity aligns with your specific thermal processing goals.

Summary Table:

| Feature | Description |

|---|---|

| Design Type | Split tube with hinged clamshell for easy access |

| Heating Zones | Single zone for uniform temperature control |

| Key Applications | Material synthesis, annealing, batch testing, R&D |

| Advantages | Quick sample handling, consistent heating, reliability |

| Limitations | No temperature gradients, batch-only processing |

Ready to enhance your lab's efficiency with a Split Tube Furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in materials science, chemistry, or R&D, our furnaces ensure reliable performance and easy operation. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide