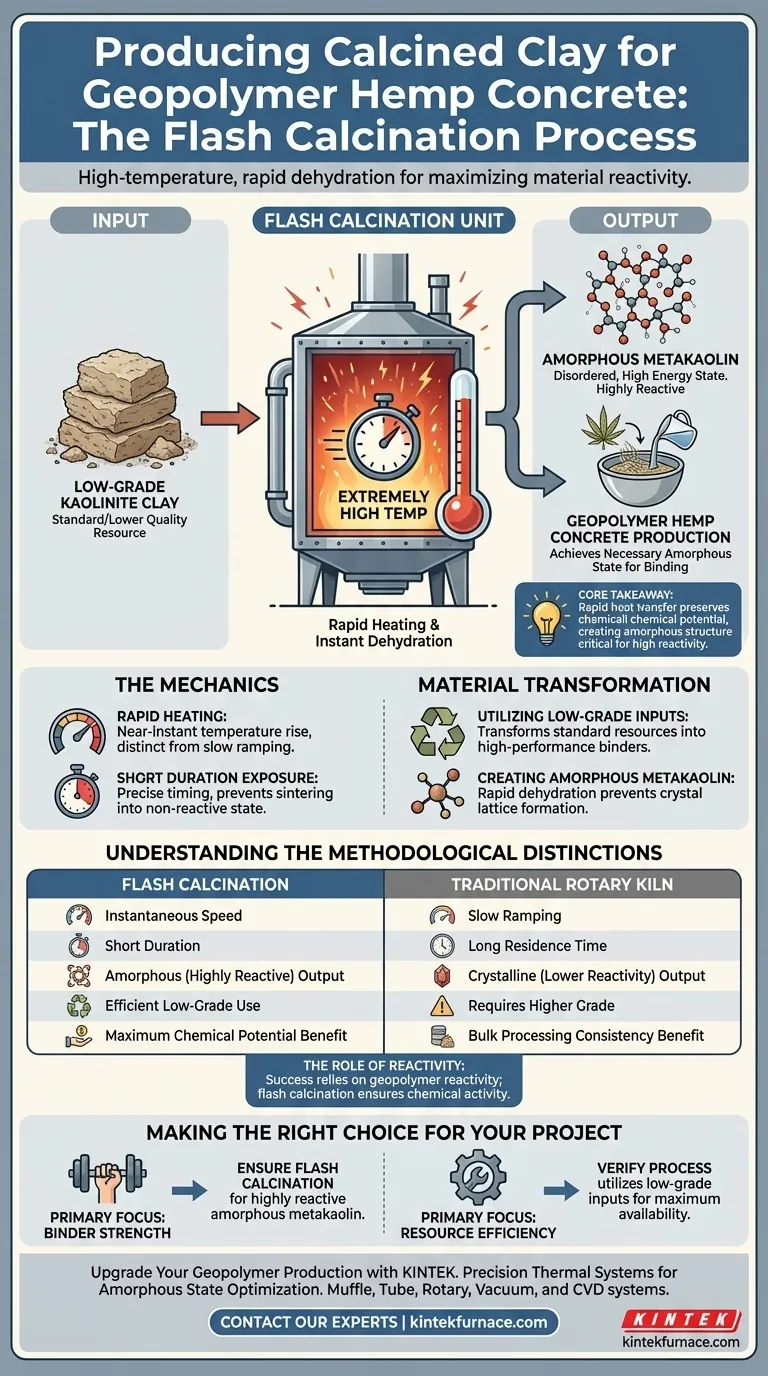

The process used to produce calcined clay for geopolymer hemp concrete is flash calcination. This technique involves subjecting low-grade kaolinite clay to high temperatures for an extremely short duration. This rapid exposure triggers immediate dehydration, transforming the raw material into amorphous metakaolin.

Core Takeaway Unlike traditional slow-roasting methods, flash calcination prioritizes rapid heat transfer to preserve the clay's chemical potential. This speed creates an amorphous structure, which is the key factor in achieving the high reactivity required for geopolymer binders.

The Mechanics of Flash Calcination

Rapid Heating

The defining characteristic of this process is the speed of heat application. Flash calcination equipment brings clay particles to high temperatures almost instantly.

This differs significantly from traditional methods, which ramp up heat slowly over time.

Short Duration Exposure

The clay remains inside the heating element for a very brief period. The goal is to alter the clay quickly without "overcooking" it or allowing it to sinter into a non-reactive state.

This precise timing ensures the material reaches the exact state necessary for geopolymerization.

Material Transformation

Utilizing Low-Grade Inputs

This process is specifically noted for its ability to process low-grade kaolinite raw materials.

It turns an otherwise standard or lower-quality resource into a high-performance industrial binder.

Creating Amorphous Metakaolin

The rapid dehydration causes a specific chemical change. It strips water from the clay structure so quickly that the molecules do not have time to align into a stable crystal lattice.

Instead, they form amorphous metakaolin. This disordered, "amorphous" state possesses high internal energy, making it highly reactive when mixed with the geopolymer activator.

Understanding the Methodological Distinctions

Flash vs. Rotary Kiln

It is critical to distinguish this process from traditional rotary kiln calcination.

Rotary kilns typically involve longer residence times and slower heating profiles. Flash calcination replaces this with high-intensity, short-duration processing to maximize reactivity.

The Role of Reactivity

The success of geopolymer hemp concrete relies on the geopolymer reactivity of the binder.

If the clay is not calcined rapidly enough, it may not achieve the necessary amorphous state. Flash calcination ensures the output is chemically active enough to bond effectively with the hemp aggregate.

Making the Right Choice for Your Project

When evaluating calcined clay sources for geopolymer applications, consider the production method to ensure material performance.

- If your primary focus is binder strength: Ensure the supplier uses flash calcination to guarantee the clay has been converted to highly reactive amorphous metakaolin.

- If your primary focus is resource efficiency: Verify that the process is capable of utilizing low-grade kaolinite inputs to maximize raw material availability.

The quality of your final concrete depends less on the raw clay's initial grade and more on the speed and precision of its thermal transformation.

Summary Table:

| Feature | Flash Calcination | Traditional Rotary Kiln |

|---|---|---|

| Heating Speed | Near-instantaneous | Slow ramping |

| Exposure Duration | Extremely short | Long residence time |

| Output Structure | Amorphous (Highly reactive) | Crystalline (Lower reactivity) |

| Raw Material Use | Efficient for low-grade kaolinite | Often requires higher grade |

| Primary Benefit | Maximum chemical potential | Bulk processing consistency |

Upgrade Your Geopolymer Production with Precision Thermal Systems

Achieving the perfect amorphous state in metakaolin requires precise temperature control and specialized heating technology. KINTEK provides the cutting-edge laboratory and industrial solutions necessary to optimize your material transformation.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to meet the unique reactivity requirements of your geopolymer hemp concrete projects.

Maximize your binder strength and resource efficiency today. Contact our thermal processing experts now to find the ideal system for your research or production needs.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do firing times compare between gas and electric kilns? Discover Which Kiln Fits Your Ceramic Art

- What ensures smooth rotation in indirectly heated rotary kilns? Discover the Key to Long-Term Reliability

- How does electromagnetic induction heating improve heating efficiency in rotary kilns? Boost Energy Savings & Speed

- What is the maximum temperature for a rotary kiln? How to Choose the Right Temperature for Your Process

- What raw materials are used in a rotary kiln? A Guide to Processing Flowing Solids

- How are rotary kilns utilized in environmental protection? Transforming Waste into Resources

- What temperature range do rotary kilns typically operate at? Optimize Your Process with Precise Heat Control

- What is the temperature range for thermal treatment processes in electrically heated indirect rotary kilns? Ideal for Precise Heat Up to 800°C