In a direct comparison, gas kilns have significantly faster firing cycles than electric kilns. Their ability to generate intense heat quickly through combustion and to cool down more rapidly means a full firing can be completed in a shorter timeframe, often within a single day. Electric kilns, by contrast, rely on radiant heat and are heavily insulated, leading to a slower, more gradual heating and cooling process.

The choice between a gas and electric kiln goes far beyond firing speed. It's a decision between the raw, atmospheric effects of combustion and the precise, repeatable control of electricity, each profoundly influencing the final character of your ceramic work.

The Mechanics of Heat: Why Firing Speeds Differ

Understanding why the firing times differ is the key to choosing the right tool. The method of heat generation and transfer is fundamentally different between the two types of kilns.

Gas Kilns: Direct Flame and Convection

A gas kiln works by burning a fuel source, like natural gas or propane. This combustion creates a live flame and hot gases that circulate throughout the kiln chamber.

This process, known as convection, transfers heat very efficiently and rapidly. The kiln's temperature can be increased quickly by simply increasing the fuel and air supply, giving the operator dynamic, real-time control over the firing's pace.

Electric Kilns: Radiant Heat and Insulation

Electric kilns generate heat by passing electricity through coiled elements made of high-resistance wire. These elements glow red-hot and radiate heat into the kiln chamber.

This is a less direct method of heating than an open flame. To be efficient, electric kilns are heavily insulated to capture and hold this radiant energy. This heavy insulation means they heat up and, just as importantly, cool down much more slowly than their gas counterparts.

How Firing Environment Impacts Your Work

The difference in speed is directly tied to a more critical factor: the kiln's atmosphere. This atmosphere has a dramatic effect on glazes and clay bodies.

The Role of Atmosphere: Reduction vs. Oxidation

Gas kilns naturally create a reduction atmosphere. By limiting the oxygen supply during combustion, the flame actively pulls oxygen molecules from the glazes and clay, causing powerful chemical changes.

Electric kilns, by default, fire in a neutral or oxidation atmosphere, which is oxygen-rich. This environment is clean and does not chemically alter the glazes in the same way. While you can introduce combustible materials to simulate reduction in an electric kiln, it is not their native environment and can cause premature wear on the heating elements.

Glaze Development and Color

The atmosphere is the single biggest factor in glaze color. The reduction environment in a gas kiln is responsible for creating classic and often unpredictable effects like deep copper reds, iron-rich celadons, and tenmokus.

The clean oxidation environment in an electric kiln produces colors that are typically more predictable, stable, and bright. If your goal is consistency and vibrant color from commercial glazes, electric firing offers unparalleled reliability.

The Cooling Rate and Special Effects

The slow, controlled cooling of a well-insulated electric kiln is essential for developing specialty glazes, most notably crystalline glazes. These glazes require specific, extended temperature holds during the cooling cycle for crystals to grow, a task for which the programmable nature of modern electric kilns is perfectly suited. Gas kilns generally cool too quickly to achieve these effects without significant effort and modification.

Understanding the Trade-offs

Choosing a kiln involves balancing speed against other critical factors like control, cost, and the desired artistic outcome.

Speed vs. Precision

Gas offers speed, but it often comes with less temperature uniformity. Firing a gas kiln requires skill to manage potential hot and cold spots, load the kiln strategically, and adjust the burners manually.

Electric kilns, especially those with digital controllers, offer exceptional precision and uniformity. You can program a highly specific firing schedule with multiple stages and holds, and the kiln will execute it perfectly time after time with minimal oversight.

Upfront Cost and Installation

Gas kilns typically have a higher upfront purchase price and more complex installation requirements, including dedicated fuel lines and robust ventilation systems.

Electric kilns are generally less expensive to purchase and far simpler to install. Many smaller models can be plugged into standard high-voltage outlets, making them accessible for home studios.

Operational Skill and Labor

Firing a gas kiln is a hands-on, labor-intensive art form. It requires the operator's constant attention to monitor temperature, atmosphere, and flame pattern.

Firing an electric kiln is a technical process that can be largely automated. Once the program is set, the kiln manages the firing cycle on its own, freeing up the artist's time.

Making the Right Choice for Your Goal

The "better" kiln is the one that aligns with your specific artistic and production needs.

- If your primary focus is speed and rich, classic reduction effects: A gas kiln is the ideal choice for achieving sought-after glaze surfaces like copper reds and celadons.

- If your primary focus is consistency, ease of use, and bright, predictable colors: An electric kiln offers unmatched reliability and precision for both hobbyists and production potters.

- If your primary focus is developing crystalline glazes or complex, multi-stage firings: The slow, programmable cooling of an electric kiln is a fundamental requirement.

Ultimately, understanding these core differences empowers you to select the kiln not just as a tool, but as a true partner in your creative process.

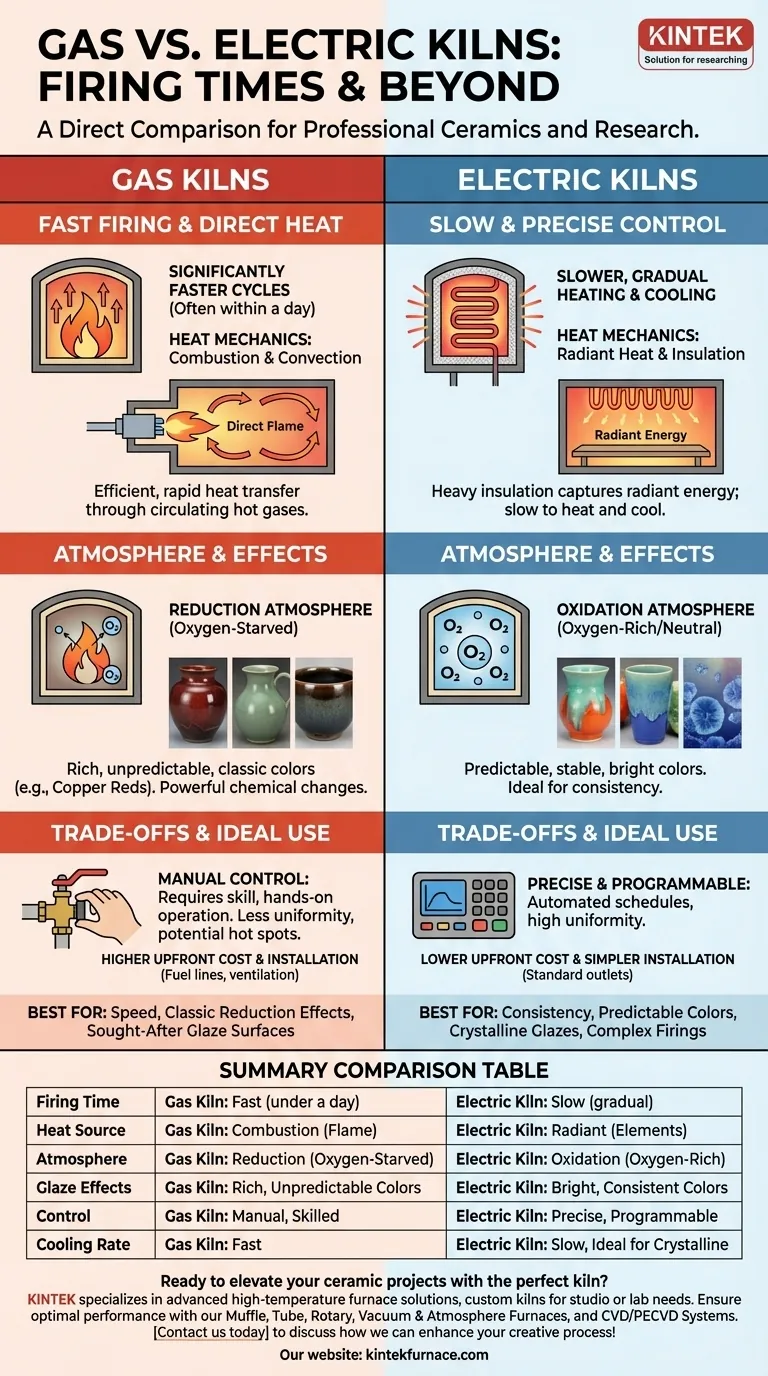

Summary Table:

| Feature | Gas Kiln | Electric Kiln |

|---|---|---|

| Firing Time | Fast (often under a day) | Slow (gradual heating/cooling) |

| Heat Source | Combustion (flame) | Radiant (electric elements) |

| Atmosphere | Reduction (oxygen-starved) | Oxidation (oxygen-rich) |

| Glaze Effects | Rich, unpredictable colors (e.g., copper reds) | Bright, consistent colors |

| Control | Manual, requires skill | Precise, programmable |

| Upfront Cost | Higher | Lower |

| Cooling Rate | Fast | Slow, ideal for crystalline glazes |

Ready to elevate your ceramic projects with the perfect kiln? KINTEK specializes in advanced high-temperature furnace solutions, including custom kilns tailored to your unique needs. Whether you're a studio artist seeking speed or a lab requiring precision, our expertise in Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems ensures optimal performance. Contact us today to discuss how we can enhance your creative process with reliable, customized equipment!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency