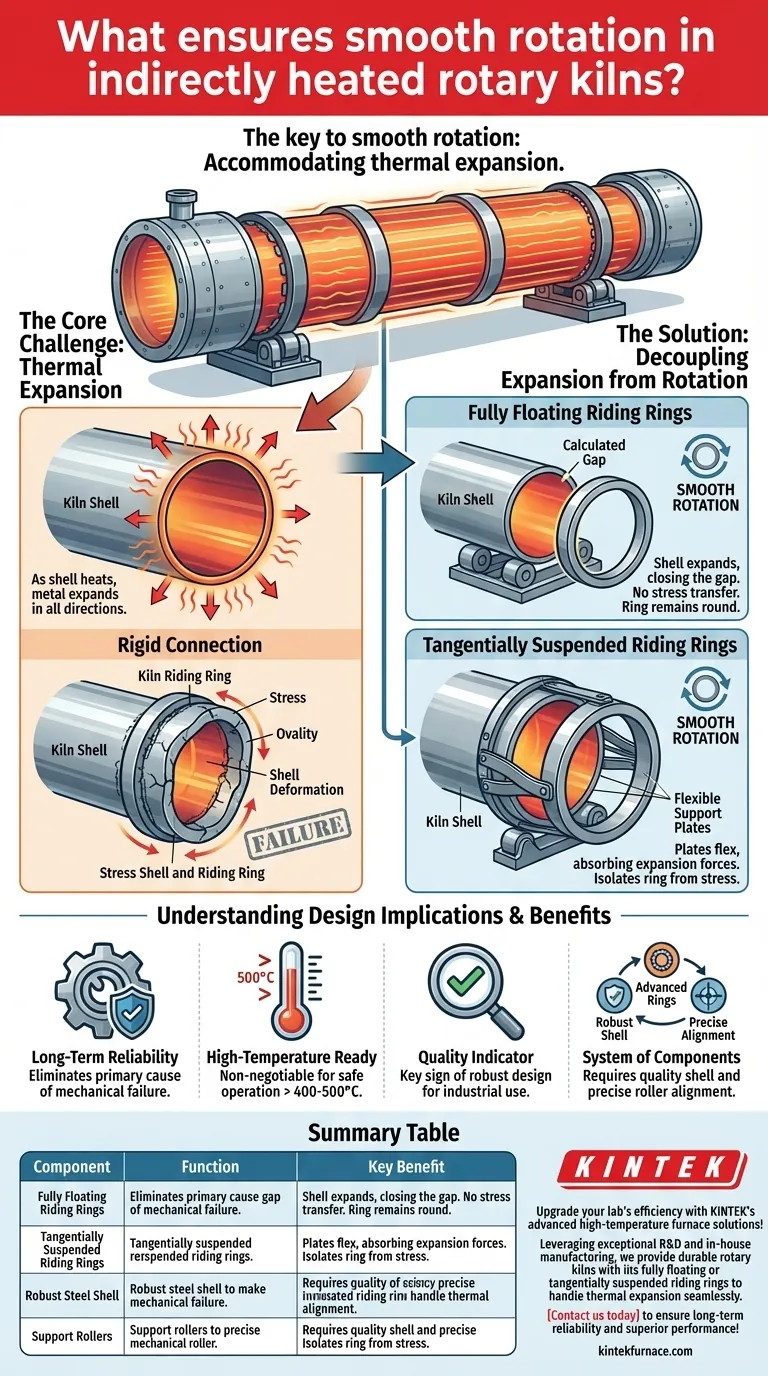

The key to smooth rotation in an indirectly heated rotary kiln lies in a design that accommodates thermal expansion. This is achieved through the use of either fully floating or tangentially suspended riding rings. These specialized components allow the hot kiln shell to expand and contract freely without deforming or damaging the support system, ensuring consistent and stable operation.

The central challenge in kiln design is not rotation itself, but managing the immense stress caused by thermal expansion. A design that isolates the kiln's structural shell from its support rings is the definitive solution for preventing deformation and ensuring long-term reliability.

The Core Challenge: Thermal Expansion

Indirectly heated kilns operate at extremely high temperatures. This heat introduces a fundamental engineering problem that dictates the entire mechanical design of the system.

Why the Kiln Shell Expands

As the robust steel shell of the kiln heats up, the metal expands in all directions. This is a basic principle of physics that cannot be avoided. This radial expansion can be significant, especially in large-diameter kilns.

The Problem with a Rigid Connection

If the riding rings (the large steel bands that rest on support rollers) were welded directly to the kiln shell, this expansion would create catastrophic stress. The shell would try to grow, but the cooler, more dimensionally stable riding rings would restrain it.

This conflict leads to shell deformation (known as ovality), high localized stress, and eventually, cracks and premature failure of the shell or welds.

The Goal: Decoupling Expansion from Rotation

The primary engineering goal is to allow the shell to "breathe"—to expand and contract with temperature changes—without distorting the riding rings. The riding rings must remain perfectly circular to ensure smooth, continuous contact with the support rollers.

How Advanced Riding Rings Provide the Solution

Fully floating and tangentially suspended designs are two proven methods for achieving this necessary decoupling. They allow the shell to expand radially while keeping the riding ring perfectly round and centered.

The Role of Riding Rings (Tires)

First, it's important to understand that riding rings, also called tires, are the primary interface between the rotating kiln drum and the stationary base. They are massive steel rings that rest on a set of support rollers, which bear the entire load of the kiln and its contents.

Fully Floating Rings Explained

A fully floating design involves a small, calculated gap between the kiln shell's outer diameter and the riding ring's inner diameter. The ring "floats" on the shell, held in position by a series of keeper bars or pads.

When the shell heats up and expands, it simply closes this gap. The expansion force is not transferred to the riding ring, which remains dimensionally stable and round, ensuring smooth rotation.

Tangentially Suspended Rings Explained

This is an alternative, more complex design. Instead of a simple gap, the riding ring is connected to the shell by a series of tangential support plates.

These plates act like leaf springs. As the shell expands, the plates flex, absorbing the outward movement. This isolates the riding ring from any expansion stress, again ensuring it remains perfectly cylindrical for smooth operation.

Understanding the Design Implications

The choice of riding ring design is a critical indicator of a kiln's quality and its suitability for a given application. It is not a minor detail.

The Weakness of Fixed Designs

Simpler, lower-cost kilns may have riding rings welded directly to the shell. This fixed design is only acceptable for very small kilns or those operating at low temperatures where thermal expansion is minimal. For most industrial processes, this design is a liability.

A System of Components

Even the best riding ring system relies on a robust steel shell. The shell must be engineered to withstand the thermal cycles and mechanical loads of the process. The floating ring system protects the shell, but the shell itself must be of high quality to begin with.

The Importance of Alignment

Smooth rotation is not just about the ring design. It also depends on the precise alignment of the support rollers. Misalignment can introduce point loading and vibration, even with a perfectly designed floating ring system. Proper installation and maintenance are critical.

Making the Right Choice for Your Goal

When evaluating an indirectly heated rotary kiln, the design of the riding rings reveals the manufacturer's understanding of fundamental engineering principles.

- If your primary focus is maximum equipment longevity: Insist on a kiln with either fully floating or tangentially suspended riding rings to eliminate the primary cause of mechanical failure.

- If you are dealing with high processing temperatures (above 400-500°C): An advanced ring design that accommodates thermal expansion is non-negotiable for safe and reliable operation.

- If you are evaluating a kiln's overall quality: The type of riding ring is a key indicator of a robust design intended for demanding, continuous industrial use versus a lighter-duty machine.

Ultimately, understanding how a kiln manages thermal expansion is the key to differentiating a durable, high-performance machine from one destined for early failure.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Fully Floating Riding Rings | Allows kiln shell to expand freely without stress transfer | Prevents deformation and ensures stable rotation |

| Tangentially Suspended Riding Rings | Uses flexible plates to absorb expansion forces | Maintains circular shape for smooth operation |

| Robust Steel Shell | Supports thermal cycles and mechanical loads | Provides durability and structural integrity |

| Support Rollers | Bear the kiln load and enable rotation | Requires precise alignment for optimal performance |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide durable rotary kilns with fully floating or tangentially suspended riding rings to handle thermal expansion seamlessly. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by deep customization to meet your unique experimental needs. Contact us today to ensure long-term reliability and superior performance for your laboratory!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating