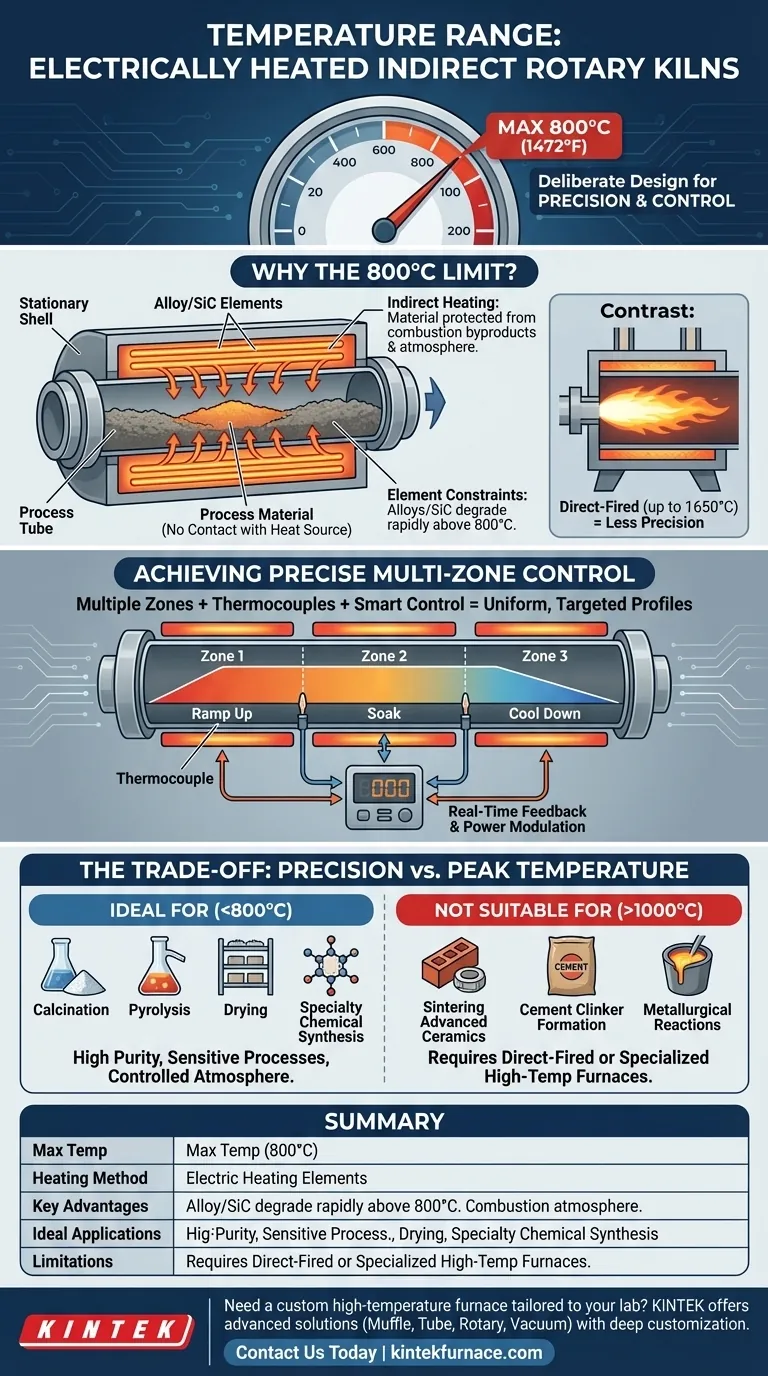

For thermal treatment, electrically heated indirect rotary kilns are specifically designed to operate at temperatures up to 800°C (1472°F). This operational ceiling is a deliberate design characteristic tied to the materials used for the heating elements and the principles of indirect heating.

While some industrial rotary kilns can reach temperatures over 1600°C, the 800°C limit on electrically heated indirect models is not a flaw. It is a trade-off that enables exceptional temperature precision and atmosphere control, making them ideal for specific, sensitive processes.

Why is Temperature Limited to 800°C?

The operational temperature of any kiln is determined by its heating method and the materials it is constructed from. For this specific type of kiln, the limit is a direct result of its design advantages.

The Role of Indirect Heating

In an indirect kiln, the material being processed never comes into contact with the heat source. Electric heating elements are positioned outside the rotating process tube, and heat is transferred through the tube wall to the material inside.

This separation is critical for protecting the process material from combustion byproducts and allowing for a precisely controlled atmosphere, but the tube wall itself creates a barrier to extreme heat transfer.

Constraints of Electric Heating Elements

The most significant factor is the material of the electric heating elements themselves.

The references mention both "alloy heating" and "silicon carbide" (SiC) elements. Standard metallic and alloy heating elements, valued for their reliability and control, begin to degrade and lose efficiency as they approach temperatures much higher than 800°C. This makes 800°C a safe and reliable upper limit for long-term industrial operation.

A Clear Contrast to Direct-Fired Kilns

General-purpose rotary kilns, which can reach 1650°C (3000°F), almost always use direct-firing. In that design, a powerful gas or oil burner injects a flame directly into the kiln, where it makes contact with the material. This is efficient for achieving brute-force high temperatures but offers far less precision and no atmospheric control.

How is Temperature Precisely Controlled?

The key advantage of an electrically heated kiln is its ability to maintain a highly accurate and uniform temperature profile. This is achieved through a sophisticated control architecture.

Multi-Zone Heating

These kilns are not heated by a single, monolithic source. They are divided into multiple, separately controllable temperature zones along the length of the kiln tube—often three or four.

This allows operators to create a specific temperature profile, for example, a gradual ramp-up, a long soak at a peak temperature, and a controlled cool-down, all within the same machine.

The Function of Thermocouples

Each heating zone is monitored by its own thermocouple. This sensor provides continuous, real-time temperature data back to the central control system.

Modulating Heat Input

The control system uses the feedback from the thermocouples to constantly adjust the power sent to the heating elements in each zone. As noted in the references, this can involve varying the number of energized elements or modulating their power output to hold the temperature precisely at the desired setpoint.

Understanding the Trade-offs: Precision vs. Peak Temperature

Choosing a kiln technology requires you to balance its capabilities with the needs of your process. Electrically heated indirect kilns present a very clear set of trade-offs.

The Advantage: Process Control and Purity

The primary benefit is unparalleled control. The ability to manage a precise temperature profile in a sealed, controlled atmosphere (such as inert nitrogen or argon) is essential for producing high-purity, sensitive materials. This makes them ideal for applications like specialty chemical synthesis, calcination of catalysts, and pyrolysis.

The Limitation: The 800°C Ceiling

The obvious trade-off is the temperature limit. These kilns are fundamentally unsuited for processes that require extreme heat, such as cement clinker formation, the sintering of many advanced ceramics, or certain metallurgical reactions that only occur well above 1000°C.

Making the Right Choice for Your Process

Selecting the correct thermal processing equipment depends entirely on your material's reaction requirements and purity goals.

- If your primary focus is on calcination, pyrolysis, drying, or synthesis below 800°C: An electrically heated indirect kiln offers the superior temperature precision and atmosphere control necessary for a successful, repeatable outcome.

- If your primary focus is on high-temperature sintering, cement production, or reactions above 1000°C: You must use a direct-fired kiln or other specialized high-temperature furnace technology, as an electrical indirect model is not suitable for your goal.

Understanding this fundamental temperature boundary is the first and most critical step in specifying the right equipment for your thermal processing needs.

Summary Table:

| Feature | Details |

|---|---|

| Maximum Temperature | Up to 800°C (1472°F) |

| Heating Method | Indirect electric heating with elements outside the process tube |

| Key Advantages | Precise temperature control, uniform heating, atmosphere purity |

| Ideal Applications | Calcination, pyrolysis, drying, specialty chemical synthesis below 800°C |

| Limitations | Not suitable for processes above 800°C, like high-temperature sintering |

Need a high-temperature furnace tailored to your lab's unique requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental needs for superior results. Contact us today to discuss how we can enhance your thermal processes!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions