In short, electromagnetic induction improves rotary kiln efficiency by fundamentally changing the heating method. Instead of heating the kiln from the outside-in, it generates heat directly inside the material being processed. This direct, internal heating drastically reduces energy waste and accelerates the entire process.

The core advantage of electromagnetic induction is its ability to bypass the inefficient, intermediate steps of traditional heating. By converting electrical energy directly into thermal energy within the target material, it eliminates the massive heat losses associated with heating the kiln shell and surrounding air first.

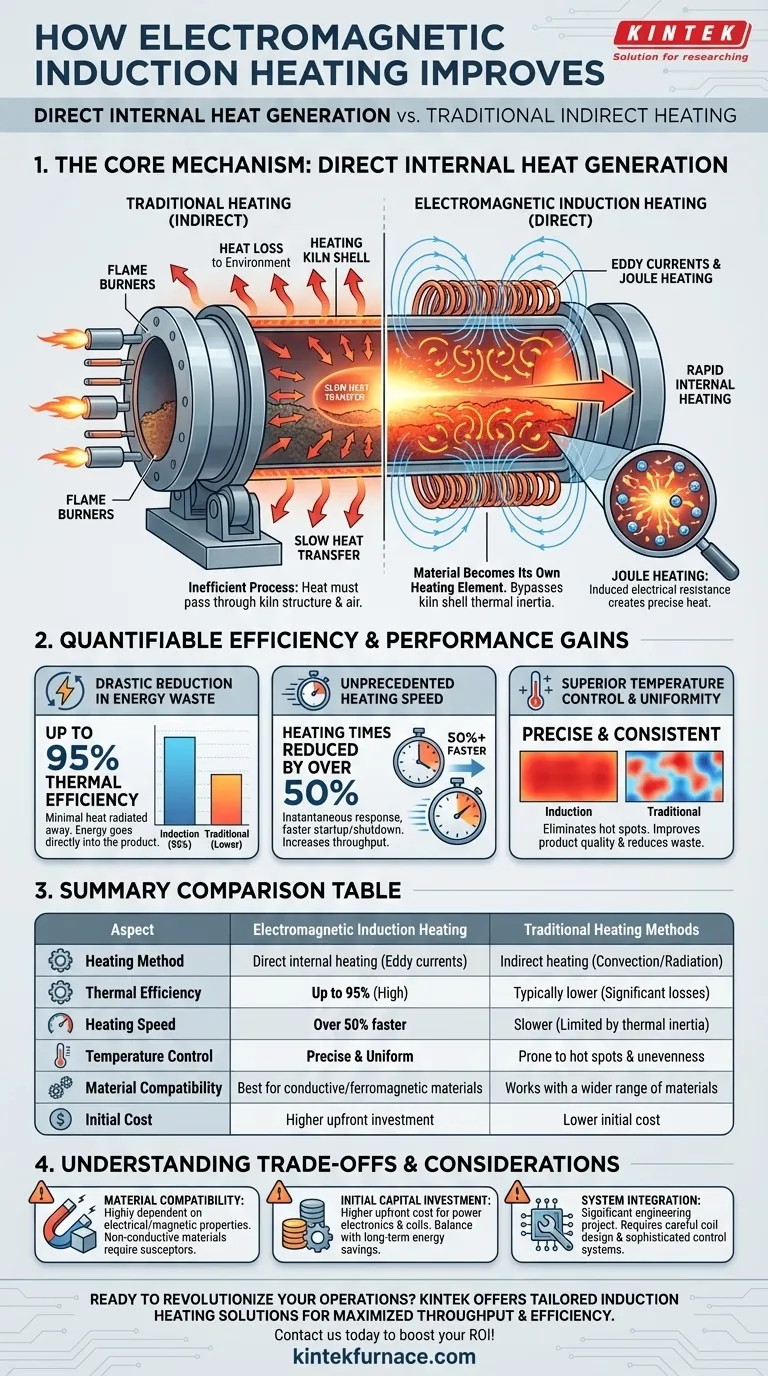

The Core Mechanism: Direct Internal Heat Generation

To understand the efficiency gains, you must first understand the fundamental difference in how heat is delivered compared to conventional methods like gas burners or resistance heaters.

From Electrical Energy to Thermal Energy

Electromagnetic induction uses a magnetic field to induce electrical eddy currents within the conductive material inside the kiln. The material's natural electrical resistance causes these currents to generate precise, internal heat—a principle known as Joule heating.

Essentially, the material becomes its own heating element.

Bypassing Conventional Heat Transfer

Traditional kilns operate on convection and radiation. A flame or heating element heats the kiln shell and the air inside, which then slowly transfers that heat to the material bed.

This indirect process is inherently inefficient, with a significant portion of energy lost to the kiln's structure and the surrounding environment before it ever reaches the product. Induction heating skips these steps entirely.

Eliminating Thermal Inertia

Because induction doesn't need to heat the massive refractory lining of the kiln shell to operating temperature, the system's response time is nearly instantaneous. This lack of thermal inertia allows for rapid temperature adjustments and dramatically faster startup and shutdown cycles.

Quantifiable Efficiency and Performance Gains

This shift in heating methodology translates into measurable improvements in key operational metrics.

Drastic Reduction in Energy Waste

The primary benefit is exceptionally high thermal efficiency, which can reach up to 95%. Since heat is generated where it's needed, very little energy is radiated away from the kiln's exterior, leading to significant reductions in energy consumption and operational cost.

Unprecedented Heating Speed

By delivering energy directly into the material, heating times can be reduced by over 50% compared to conventional systems. This directly increases the kiln's throughput and overall production capacity without enlarging its physical footprint.

Superior Temperature Control and Uniformity

Induction heating is incredibly precise and uniform. It eliminates the hot spots and uneven temperature distribution common in traditionally fired kilns. This leads to higher, more consistent product quality and less material waste from under- or over-processing.

Understanding the Trade-offs and Considerations

While powerful, electromagnetic induction is not a universal solution. A clear-eyed assessment of its limitations is crucial for making an informed decision.

Material Compatibility

This method's effectiveness is highly dependent on the electrical and magnetic properties of the material being processed. It works best with electrically conductive or ferromagnetic materials. Non-conductive materials cannot be heated directly and would require the use of conductive susceptors mixed in, adding complexity.

Initial Capital Investment

The upfront cost for an electromagnetic induction system, including the power electronics and induction coils, is typically higher than that of a conventional gas-fired or resistance-heated system. The long-term energy savings must be weighed against this initial capital expenditure.

System Integration and Complexity

Retrofitting an existing rotary kiln for induction heating is a significant engineering project. It requires careful design of the induction coils to fit the kiln geometry and integration of a sophisticated power and control system. This is not a simple drop-in replacement.

Making the Right Choice for Your Operation

The decision to adopt induction heating should be driven by your specific operational priorities and material characteristics.

- If your primary focus is maximizing throughput and energy savings: The speed and up to 95% thermal efficiency of induction heating present a compelling case for long-term ROI.

- If your primary focus is product quality and process control: The precise, uniform heat provided by induction offers unmatched consistency, reducing defects and improving final product value.

- If you are processing diverse or non-conductive materials: A thorough feasibility study is critical to determine if induction is viable or if traditional heating methods remain more practical.

Ultimately, choosing induction heating is a strategic investment in process intensification, not just an equipment upgrade.

Summary Table:

| Aspect | Electromagnetic Induction Heating | Traditional Heating Methods |

|---|---|---|

| Heating Method | Direct internal heating via eddy currents | Indirect heating via convection/radiation |

| Thermal Efficiency | Up to 95% | Typically lower due to heat losses |

| Heating Speed | Over 50% faster | Slower, limited by thermal inertia |

| Temperature Control | Precise and uniform | Prone to hot spots and unevenness |

| Material Compatibility | Best for conductive/ferromagnetic materials | Works with a wider range of materials |

| Initial Cost | Higher upfront investment | Lower initial cost |

Ready to revolutionize your rotary kiln operations with advanced electromagnetic induction heating?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs.

Whether you're aiming to maximize throughput, achieve superior energy savings, or enhance product quality, our induction heating systems can deliver up to 95% thermal efficiency and faster processing times.

Contact us today to discuss how we can optimize your heating processes and boost your ROI!

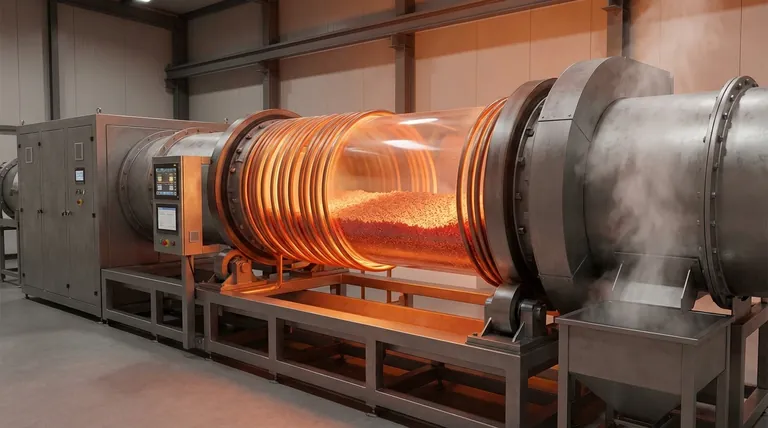

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource