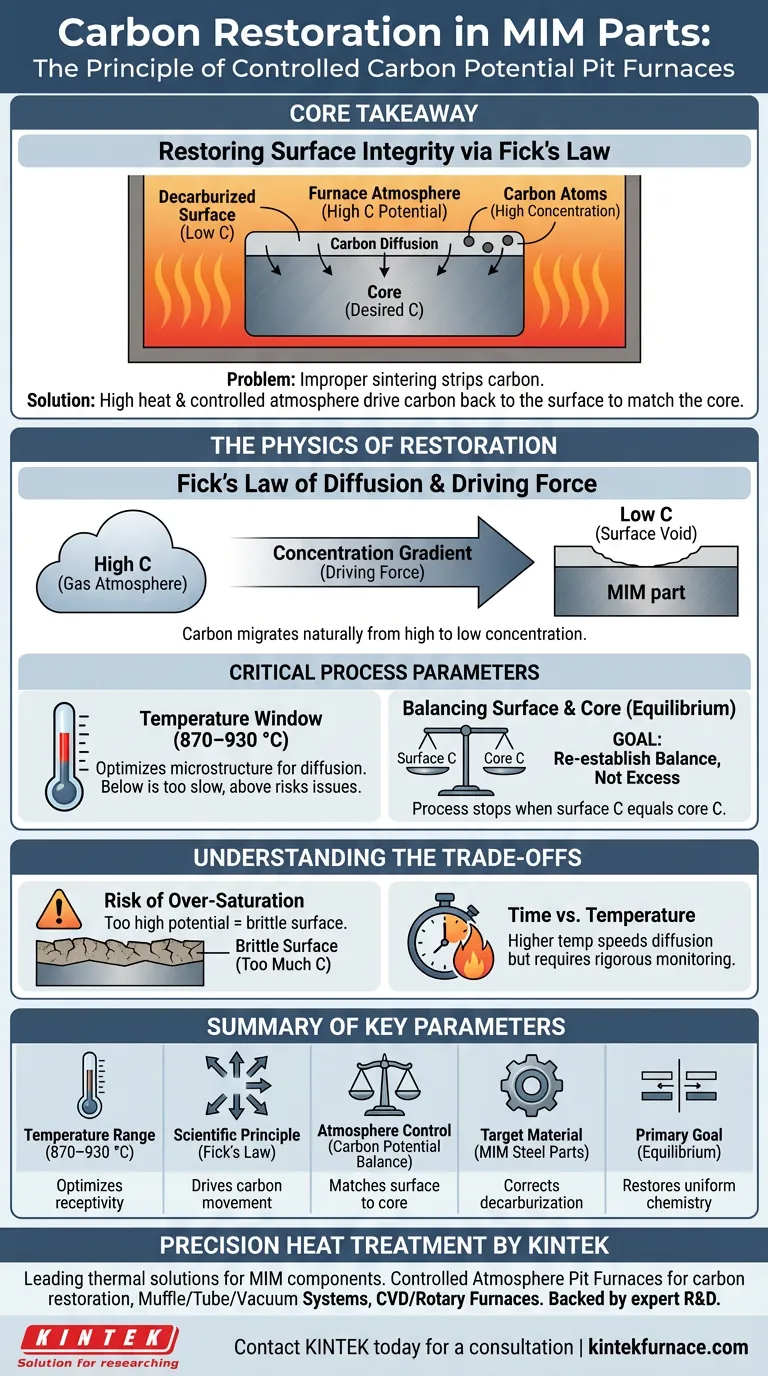

The principle behind carbon restoration in a controlled carbon potential pit furnace is the corrective application of Fick's Law of Diffusion. By exposing Metal Injection Molding (MIM) parts to a specific temperature range (870–930 °C) and a carbon-rich atmosphere, the furnace drives carbon atoms back into the steel's depleted surface layer until it reaches equilibrium with the core.

Core Takeaway: Improper sintering atmospheres can strip carbon from steel surfaces, weakening the part. A controlled carbon potential furnace uses high heat and atmospheric pressure to force carbon back into the steel, restoring the material's surface chemistry to match its internal core.

The Physics of Restoration

Fick's Law of Diffusion

The scientific foundation of this process is Fick's Law. This law dictates that particles—in this case, carbon atoms—will naturally migrate from an area of high concentration to an area of low concentration.

The Concentration Gradient

Because the MIM part has a decarburized (low carbon) surface, the furnace creates a "carbon potential" in the atmosphere that is higher than the surface but equal to the desired core specification.

Driving Force

This difference in concentration creates a driving force. Carbon atoms from the gas atmosphere penetrate the steel's surface to fill the "void" left by previous processing errors.

Critical Process Parameters

The Temperature Window

Carbon restoration requires a specific thermal environment to function correctly. The process is typically conducted between 870 and 930 °C.

Why This Range Matters

At these temperatures, the microstructure of the steel is receptive to diffusion. Below this range, diffusion is too slow; significantly above it, you risk other metallurgical issues.

Balancing Surface and Core

The ultimate goal is not to add excess carbon (which would be carburizing), but to re-establish a balance. The process stops when the carbon content at the surface equals the carbon content at the core.

Understanding the Trade-offs

Risk of Over-Saturation

Precise control of the atmosphere is non-negotiable. If the carbon potential in the furnace is set too high, you will overshoot the target, resulting in a brittle surface with too much carbon.

Time vs. Temperature

While higher temperatures within the 870–930 °C range speed up diffusion, they also require more rigorous monitoring to prevent grain growth or distortion in the MIM parts.

Making the Right Choice for Your Goal

To effectively utilize a pit furnace for carbon restoration, you must align the process with your quality requirements.

- If your primary focus is correcting sintering errors: Ensure the furnace's carbon potential strictly matches the specific alloy's required carbon content to avoid creating a new problem.

- If your primary focus is process efficiency: Operate closer to the 930 °C upper limit to maximize the rate of diffusion, but increase the frequency of atmosphere sampling.

Mastering this equilibrium ensures your MIM parts maintain uniform strength and hardness from the inside out.

Summary Table:

| Parameter | Specification | Purpose in Carbon Restoration |

|---|---|---|

| Temperature Range | 870 – 930 °C | Optimizes microstructure receptivity for carbon diffusion |

| Scientific Principle | Fick's Law of Diffusion | Drives carbon from high concentration (gas) to low (steel surface) |

| Atmosphere Control | Carbon Potential Balance | Matches the surface carbon content to the internal core |

| Target Material | MIM Steel Parts | Corrects decarburization caused by improper sintering atmospheres |

| Primary Goal | Equilibrium | Restores uniform surface chemistry without over-saturating |

Precision Heat Treatment for Critical MIM Components

Don't let decarburization compromise the strength and hardness of your Metal Injection Molding parts. KINTEK provides industry-leading thermal solutions designed to restore material integrity and ensure uniform quality.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of high-temperature laboratory equipment, including:

- Controlled Atmosphere Pit Furnaces for precise carbon restoration.

- Muffle, Tube, and Vacuum Systems for versatile thermal processing.

- CVD and Rotary Furnaces tailored to advanced material synthesis.

Whether you need to correct sintering errors or optimize process efficiency, KINTEK’s customizable systems are engineered to meet your unique metallurgical needs.

Ready to elevate your material performance? Contact KINTEK today for a consultation!

Visual Guide

References

- Jorge Luis Braz Medeiros, Luciano Volcanoglo Biehl. Effect of Sintering Atmosphere Control on the Surface Engineering of Catamold Steels Produced by MIM: A Review. DOI: 10.3390/surfaces9010007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the typical applications of an atmosphere furnace? Unlock Precision in Metal and Material Processing

- What are the common gases and vapors used in furnace atmospheres and their roles? Optimize Your Heat Treatment Process

- Why is it necessary to conduct the heat treatment of maraging steel powder within a controlled Argon atmosphere?

- How do atmosphere furnaces contribute to improved material properties? Unlock Superior Strength and Finish

- Why might some industries still require retort-based furnace designs? Ensure Absolute Atmospheric Control for Sensitive Processes

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How is atmosphere control managed during furnace operation? Master Precise Gas Environments for Superior Results

- How does the atmosphere protection muffle furnace distribute temperature evenly in the working chamber? Discover the Key to Uniform Heating