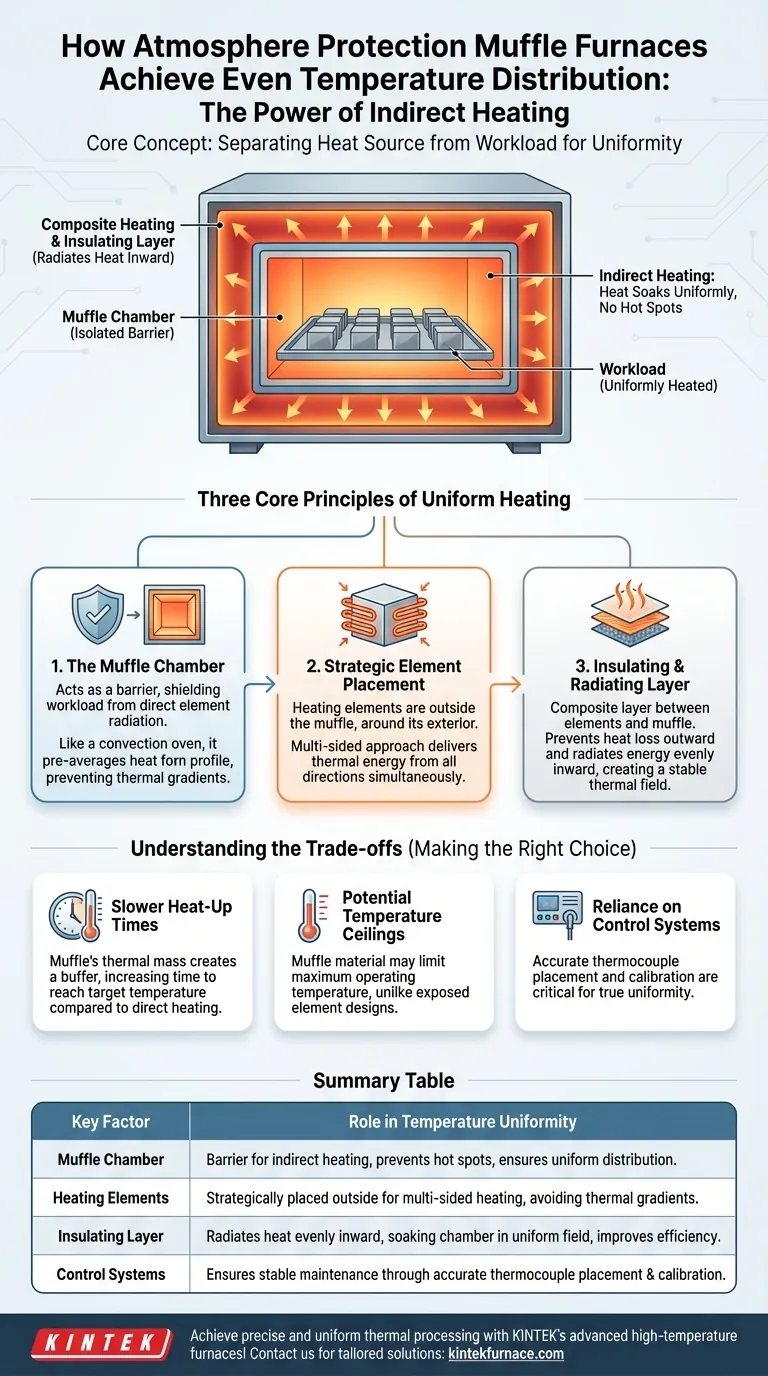

At its core, an atmosphere protection muffle furnace achieves even temperature distribution through a design that separates the heating source from the workload. This is accomplished by placing the heating elements outside of an inner chamber, or "muffle," and surrounding it with a specialized composite layer of heating and insulating materials. This design prevents direct, uneven radiation and allows heat to soak into the chamber uniformly from all sides.

The key to temperature uniformity is indirect heating. By heating a separate inner chamber (the muffle) instead of the workload directly, the furnace eliminates hot spots and ensures the entire processing volume reaches and maintains a consistent, stable temperature.

The Core Principles of Uniform Heating

To understand how a muffle furnace guarantees consistent results, it's essential to look at the three key design elements working in concert. These principles move beyond simply generating heat to controlling its precise distribution.

The Role of the "Muffle" Chamber

The defining feature of this furnace is the muffle itself—an isolated inner chamber that holds the samples or components.

This chamber acts as a barrier, shielding the workload from the intense, direct radiant heat of the elements. Think of it like a convection oven versus a broiler; instead of being blasted from one direction, your parts are bathed in heat that has been pre-averaged and equalized by the chamber walls.

This isolation is critical for preventing thermal gradients and ensuring every part of your sample experiences the same temperature profile.

Strategic Placement of Heating Elements

The heating elements in a muffle furnace are not located inside the working chamber. Instead, they are strategically arranged around the exterior of the muffle.

This multi-sided heating approach ensures that thermal energy is delivered to the muffle from multiple directions simultaneously. This prevents one side of the chamber from getting hotter than another, a common problem in simpler furnace designs.

The Insulating and Radiating Layer

Between the external heating elements and the inner muffle is a composite layer of heating and insulating materials.

This layer serves two purposes. First, the insulation prevents heat from escaping outward, improving efficiency. Second, and more importantly for uniformity, this mass absorbs energy from the elements and radiates it evenly inward, gently "soaking" the muffle chamber in a uniform thermal field.

Understanding the Trade-offs

This elegant design for uniformity is not without its compromises. Understanding them is key to determining if a muffle furnace is the right tool for your specific application.

Slower Heat-Up Times

Because the furnace must first heat the muffle, which in turn heats the workload, the overall time to reach the target temperature is generally longer than in a direct-heating furnace. The thermal mass of the muffle creates a buffer that slows down temperature changes in both directions.

Potential Temperature Ceilings

The material of the muffle itself (often a ceramic or high-nickel alloy) can impose a limit on the furnace's maximum operating temperature. Furnaces with exposed elements may be able to reach higher temperatures, albeit with a significant sacrifice in uniformity.

Reliance on Proper Control Systems

Achieving true uniformity depends on an accurate control system. The placement of the control thermocouple is critical. If it's not in a representative location within the chamber, the controller may maintain a stable temperature at that single point while other areas deviate.

Making the Right Choice for Your Goal

By understanding the principles of indirect heating, you can select and operate your equipment to achieve precise, repeatable results.

- If your primary focus is process consistency and material integrity: The muffle furnace's superior temperature uniformity is essential for sensitive applications like annealing, sintering, and chemical vapor deposition.

- If your primary focus is rapid heating cycles: You may need to accept the trade-off of a longer heat-up time or consider a direct-heating furnace if a slight lack of uniformity is acceptable for your process.

- If your primary focus is long-term reliability: Regularly verify your furnace's temperature uniformity with multi-point checks and ensure the control thermocouple is calibrated and positioned correctly.

Understanding these design principles empowers you to control your thermal processes with confidence and precision.

Summary Table:

| Key Factor | Role in Temperature Uniformity |

|---|---|

| Muffle Chamber | Acts as a barrier for indirect heating, preventing hot spots and ensuring uniform heat distribution. |

| Heating Elements | Strategically placed around the muffle exterior for multi-sided heating to avoid thermal gradients. |

| Insulating Layer | Radiates heat evenly inward, soaking the chamber in a uniform thermal field while improving efficiency. |

| Control Systems | Ensures stable temperature maintenance through accurate thermocouple placement and calibration. |

Achieve precise and uniform thermal processing with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met with reliability and efficiency. Contact us today to enhance your lab's performance and get expert support!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance