In short, retort-based furnace designs are required for specialized industrial processes where absolute control over the processing atmosphere is non-negotiable. Their defining feature is a sealed inner vessel, or "retort," which creates a gas-tight environment that isolates parts from any potential contamination, a level of purity that standard furnace designs cannot guarantee.

The decision to use a retort furnace is driven by a single, critical need: process integrity. When a material or component's final properties are acutely sensitive to atmospheric contamination, the sealed, isolated environment of a retort is not a luxury—it is a fundamental requirement for success.

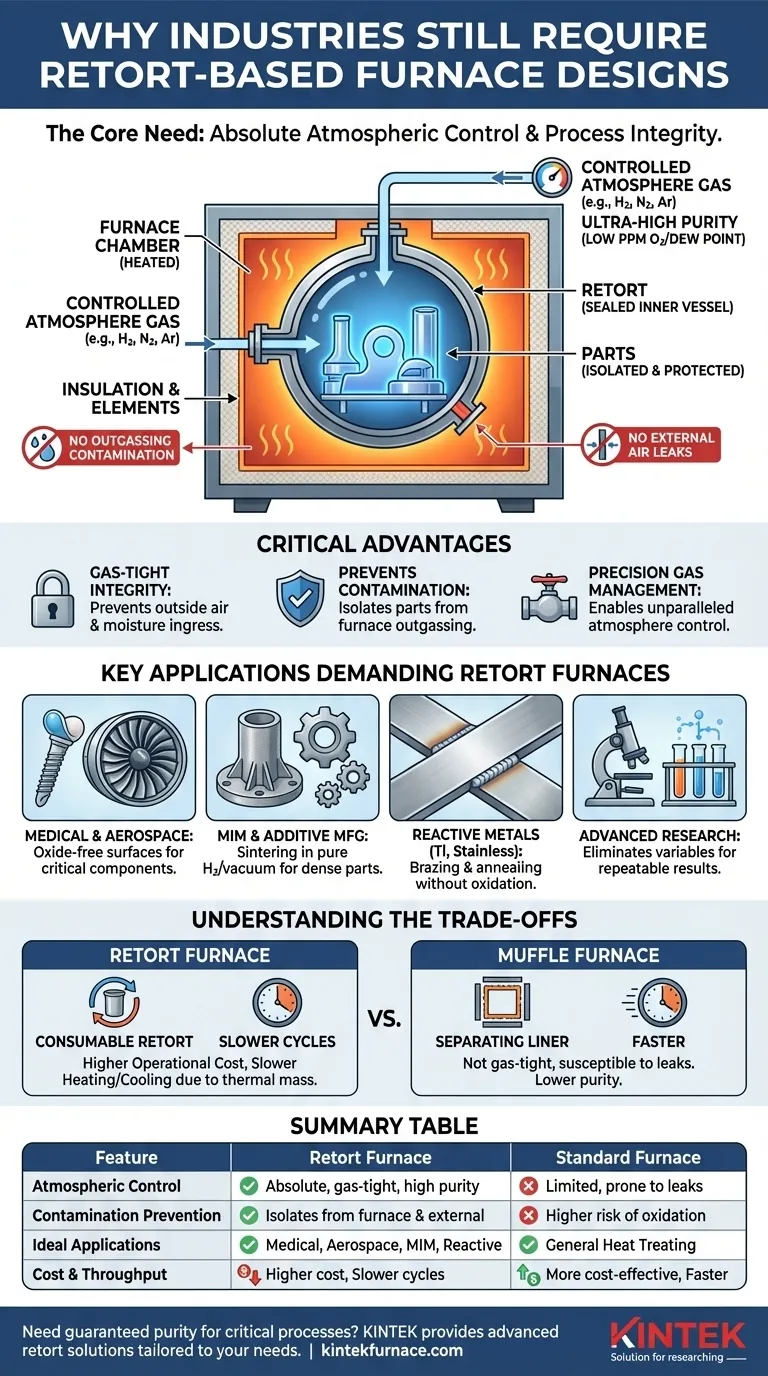

The Core Principle: Absolute Atmospheric Control

To understand the need for a retort, we must first differentiate it from other furnace types. The key is not the heat source, but how the processing environment is contained and managed.

What is a Retort?

A retort is a sealed container, typically made of high-temperature metal alloys or ceramics, that is placed inside the heated chamber of a furnace.

The parts being processed are loaded into this retort, not into the main furnace chamber. The retort is then purged of air and filled with a precise mixture of process gases.

The Critical Advantage: Gas-Tight Integrity

The retort acts as a perfect barrier. This isolation is crucial for two reasons:

- It prevents contamination from the furnace. Standard furnace chambers contain insulation, heating elements, and other materials that can "outgas" (release trace amounts of vapor) at high temperatures, contaminating the part's surface.

- It prevents contamination from the outside. The sealed and often welded construction of a retort prevents ambient air from leaking into the process environment, which would introduce oxygen and moisture.

Precision Gas Management

Because the retort is a closed system with a known volume, it allows for unparalleled control over the atmosphere. Process gases like hydrogen, nitrogen, or argon can be introduced, circulated, and maintained at exceptionally high purity levels.

This enables precise management of atmospheric conditions like dew point and oxygen levels, often down to a few parts-per-million (PPM). Standard atmosphere furnaces, which simply flood a larger, unsealed chamber with gas, cannot achieve this level of control.

Industries and Applications Demanding Retort Furnaces

This need for absolute atmospheric purity is why retorts are indispensable in several high-stakes industries.

Medical Device and Aerospace

For components like medical implants or jet engine turbine blades, any surface oxidation or contamination is a potential point of failure. A retort furnace ensures that processes like annealing or brazing occur in a perfectly inert or active atmosphere, resulting in a clean, uncontaminated surface finish.

Metal Injection Molding (MIM) and Additive Manufacturing

The sintering step in MIM and many metal 3D printing processes is extremely sensitive to atmospheric conditions. Sintering requires a pure, dry hydrogen or vacuum atmosphere to remove binder remnants and fuse the metal particles into a dense, solid part. Oxygen or moisture would inhibit this process and lead to weak, porous components.

Brazing and Annealing of Reactive Metals

Metals like stainless steel, titanium, and other superalloys are highly reactive with oxygen, especially at elevated temperatures. A retort provides the pure, oxygen-free environment (often high-purity hydrogen or argon) needed to create strong, clean brazed joints or to anneal the material without forming a detrimental oxide layer.

Advanced Materials and Research

When developing new alloys or materials, scientists need to eliminate all process variables. A retort furnace provides a perfectly controlled and repeatable environment, ensuring that the experimental results are a true reflection of the material's properties, not a byproduct of atmospheric contamination.

Understanding the Trade-offs

While essential for specific applications, retort furnaces are not universally superior. Their design comes with inherent trade-offs compared to other common furnace types.

Comparison with Muffle Furnaces

A muffle is a separating liner within a furnace, but it is not typically sealed to the same gas-tight standard as a retort. While a muffle provides good separation from heating elements, it is more susceptible to minor leaks and cannot achieve the ultra-high purity atmosphere of a true retort.

The Costs of Purity

Retort-based systems have a higher operational cost. The retorts themselves are consumables that degrade over time due to thermal cycling and must be periodically replaced.

Furthermore, the additional thermal mass of the retort means that heating and cooling cycles can be slower compared to retort-less designs, potentially impacting overall throughput for less-critical applications.

Selecting the Right Furnace for Your Process

Choosing the correct furnace technology comes down to matching the equipment's capabilities to the strict requirements of your process and material.

- If your primary focus is preventing any surface oxidation or contamination on sensitive materials: A retort furnace is the only design that provides the necessary gas-tight integrity for guaranteed results.

- If your primary focus is general heat treating with a protective atmosphere (e.g., neutral hardening): A standard atmosphere or sealed muffle furnace is often more cost-effective and perfectly sufficient.

- If your primary focus is high-volume production where minor surface oxidation is acceptable or removed later: A continuous mesh-belt furnace may offer better throughput and lower operational costs.

Ultimately, investing in a retort furnace is a decision to prioritize absolute process control and repeatability above all else.

Summary Table:

| Feature | Retort Furnace | Standard Furnace |

|---|---|---|

| Atmospheric Control | Absolute, gas-tight with high purity | Limited, prone to leaks and contamination |

| Contamination Prevention | Isolates parts from furnace and external air | Higher risk of oxidation and outgassing |

| Ideal Applications | Medical devices, aerospace, MIM, reactive metals | General heat treating, less critical processes |

| Cost and Throughput | Higher operational costs, slower cycles | More cost-effective, faster for high volume |

Need a furnace that guarantees purity for your critical processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're in medical, aerospace, or advanced materials, we ensure absolute atmospheric control and process integrity. Contact us today to discuss how our retort furnaces can elevate your lab's performance!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality