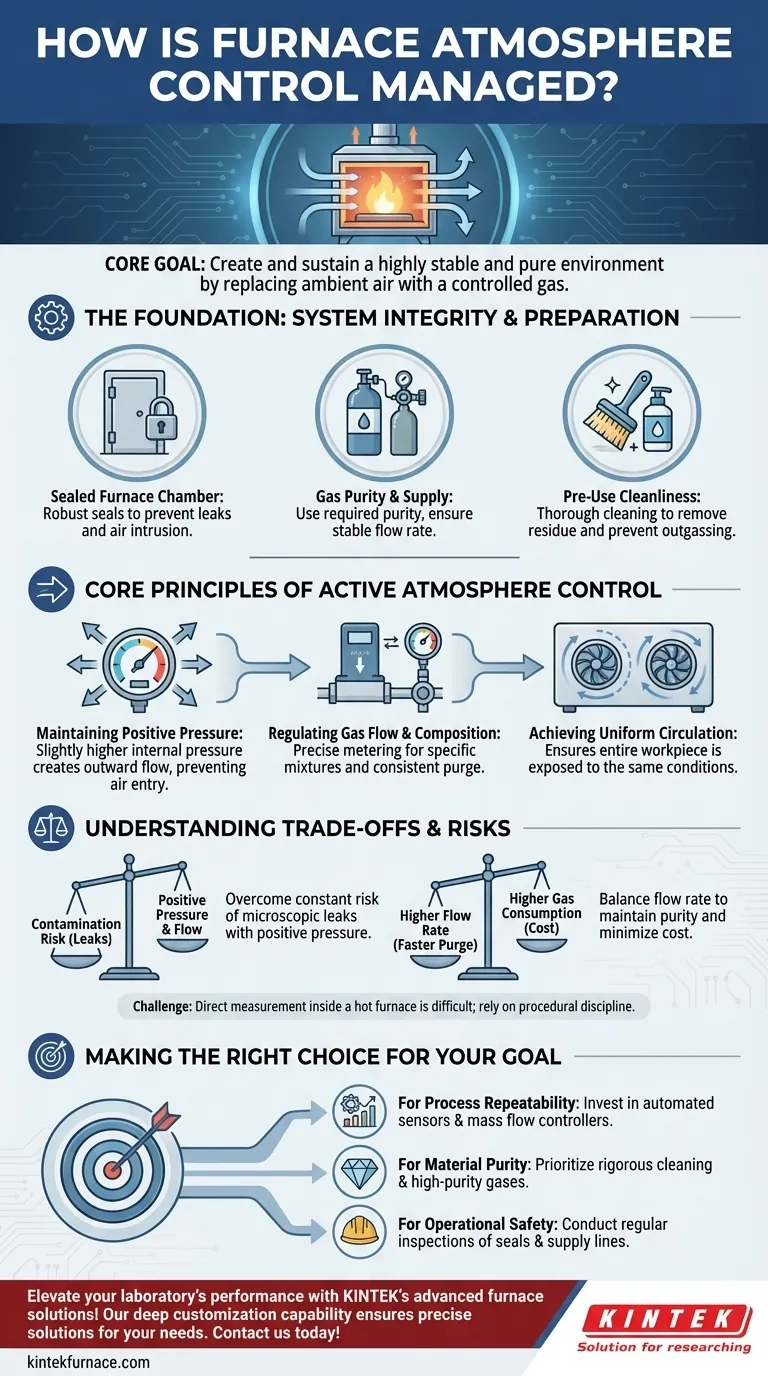

At its core, atmosphere control in a furnace is a systematic process of replacing the ambient air with a specific, controlled gas environment and maintaining its purity and stability throughout a high-temperature cycle. This is achieved by using a sealed furnace chamber, precisely regulating the flow and pressure of a chosen gas, and continuously monitoring the system to prevent contamination from outside air.

The central goal of atmosphere control is not merely to introduce a gas, but to create and sustain a highly stable and pure environment. Success depends on a disciplined approach that combines a physically sealed system with precise, active control over gas pressure and flow.

The Foundation: System Integrity and Preparation

Before any process begins, the physical state of the furnace is the primary factor in successful atmosphere control. Without a sound foundation, active gas management will be ineffective.

Ensuring a Sealed Furnace Chamber

The furnace must be engineered with robust seals to be as airtight as possible. This design is the first line of defense against gas leaks and, more critically, the intrusion of external air, which contains oxygen and moisture that can ruin sensitive processes.

Verifying Gas Purity and Supply

The process begins with the source. You must use a gas of the required purity for your application and ensure the supply line can provide a stable flow rate. Fluctuations in supply can disrupt the delicate pressure balance inside the chamber.

The Importance of Pre-Use Cleanliness

Any residue, oil, or particulate matter left inside the furnace from previous runs can outgas at high temperatures. This releases contaminants directly into your controlled atmosphere, compromising the experiment. A thorough pre-cleaning protocol is essential.

Core Principles of Active Atmosphere Control

Once the system is prepared, active management begins. These principles work together to create the desired processing conditions.

Maintaining Positive Pressure

This is the most critical active control principle. By ensuring the gas pressure inside the furnace is slightly higher than the external atmospheric pressure, you create a constant outward flow. If any microscopic leaks exist, the controlled gas will flow out, preventing ambient air from flowing in.

Regulating Gas Flow and Composition

Modern atmosphere control systems use sensors and mass flow controllers to precisely meter the gases entering the furnace. This allows for creating specific gas mixtures and maintaining a consistent flow rate, which is essential for purging the chamber and maintaining positive pressure.

Achieving Uniform Circulation

Simply filling the chamber with gas is not sufficient. The atmosphere must be uniform to ensure the entire workpiece is exposed to the same conditions. This is often aided by the furnace's design or internal fans to promote circulation and prevent stagnant pockets.

Understanding the Trade-offs and Risks

Effective atmosphere control requires balancing competing factors and understanding potential points of failure.

The Inevitable Risk of Contamination

No furnace is perfectly sealed. The primary goal of positive pressure and consistent gas flow is to overcome the constant risk of contamination from microscopic leaks. The moment pressure is lost, ambient air will begin to infiltrate the chamber.

Flow Rate vs. Gas Consumption

A higher gas flow rate can purge the chamber of contaminants more quickly and more effectively compensate for small leaks. However, this comes at the cost of significantly higher gas consumption. The goal is to find the minimum flow rate that reliably maintains purity and positive pressure.

The Challenge of Direct Measurement

While you can easily monitor temperature, pressure, and gas flow rates, directly measuring the precise atmospheric purity inside a hot furnace is extremely difficult. This is why procedural discipline—cleanliness, purging, and maintaining pressure—is relied upon to infer and ensure a pure environment.

Making the Right Choice for Your Goal

Your specific objective dictates where you should focus your efforts for atmosphere control.

- If your primary focus is process repeatability: Invest in a system with high-quality automated sensors and mass flow controllers to ensure gas flow and pressure are identical for every run.

- If your primary focus is material purity: Prioritize rigorous pre-use cleaning, using high-purity source gases, and consistently maintaining positive pressure to prevent any oxygen or moisture contamination.

- If your primary focus is operational safety: Conduct regular inspections of all furnace seals, gaskets, and gas supply lines to ensure complete system integrity.

Ultimately, disciplined control over the furnace environment is the key to achieving predictable and successful material processing results.

Summary Table:

| Aspect | Key Details |

|---|---|

| System Integrity | Sealed chamber, gas purity verification, pre-cleaning to prevent contamination |

| Active Control | Positive pressure maintenance, precise gas flow regulation, uniform circulation |

| Trade-offs | Balancing contamination risks, gas consumption, and measurement challenges |

| Goal Alignment | Focus on repeatability, purity, or safety based on specific objectives |

Elevate your laboratory's performance with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to discuss how we can enhance your atmosphere control processes and achieve superior results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process