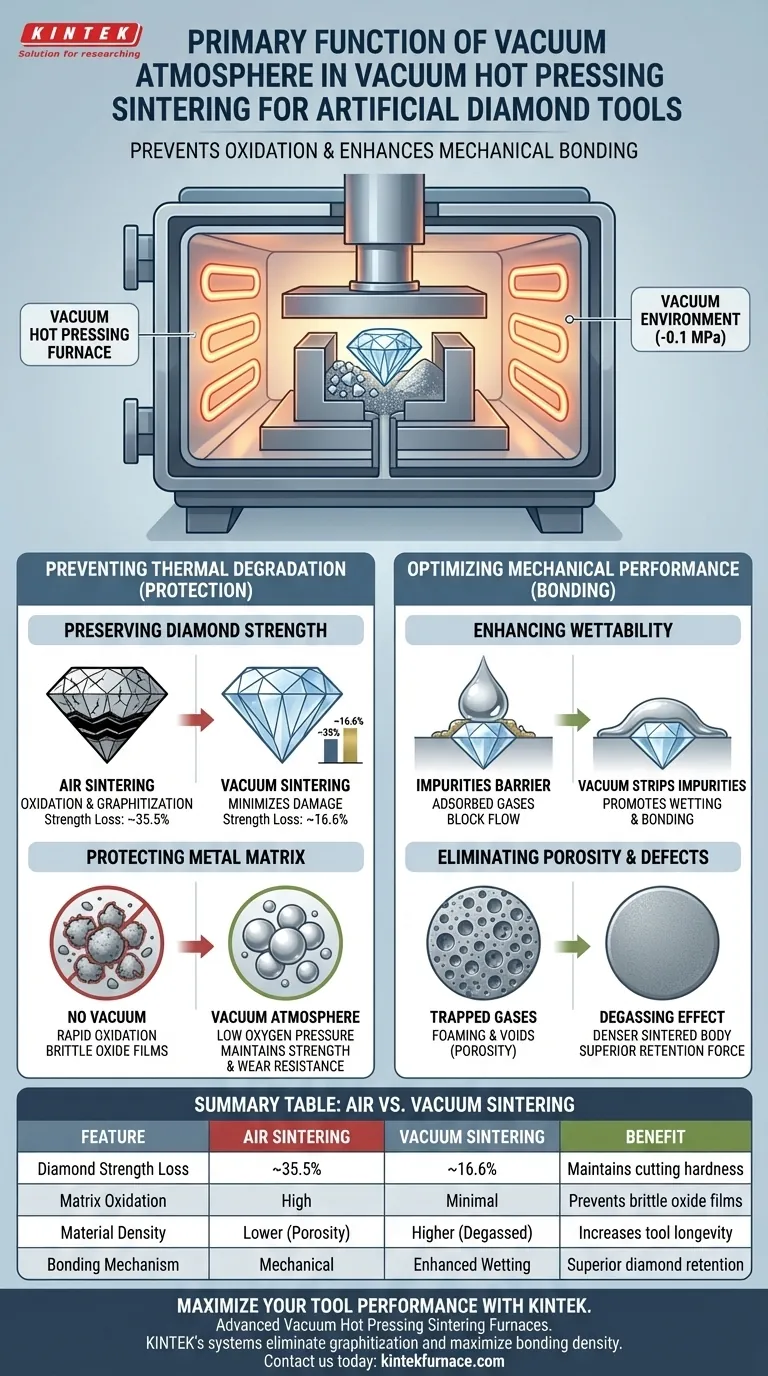

The primary function of the vacuum atmosphere in a vacuum hot pressing sintering furnace is to prevent the oxidation of both the diamond and the metal matrix while simultaneously enhancing mechanical bonding. By maintaining a low-pressure environment (typically -0.1 MPa), the furnace minimizes thermal damage to the diamond—reducing strength loss significantly compared to air sintering—and actively removes adsorbed gases to ensure the metal matrix firmly retains the diamond particles.

Core Takeaway: The vacuum atmosphere serves as both a protective shield and a bonding catalyst. It prevents the chemical degradation of diamonds and alloy elements at high temperatures while purifying powder surfaces to maximize density and tool life.

Preventing Thermal Degradation

The most immediate risk during the high-temperature sintering of diamond tools is chemical reaction with the surrounding air. The vacuum atmosphere mitigates this through two key mechanisms.

Preserving Diamond Strength

At temperatures approaching 1000°C, diamonds are highly susceptible to oxidation and graphitization. When diamonds graphitize, they lose their hardness and structural integrity.

Data indicates that sintering in a vacuum reduces diamond strength loss from approximately 35.5% (in air) to just 16.6%. By removing oxygen, the vacuum ensures the diamond retains the cutting ability required for high-performance tools.

Protecting the Metal Matrix

The metal powder holding the diamonds—often containing Copper (Cu), Tungsten Carbide (WC), or Manganese—is equally sensitive to heat.

Without a vacuum, these elements oxidize rapidly, forming brittle oxide films. The vacuum environment lowers the oxygen partial pressure, preventing these reactions and maintaining the intended strength and wear resistance of the matrix.

Optimizing Mechanical Performance

Beyond protection, the vacuum atmosphere plays an active role in the physical formation of the tool. It changes how the materials interact at a microscopic level.

Enhancing Wettability

For a diamond tool to be durable, the molten metal binder must thoroughly coat (wet) the diamond particles.

Adsorbed gases and surface impurities on the powder particles act as barriers to this flow. The vacuum strips these impurities away, promoting the wetting and bonding of the liquid phase metal to both the diamond and the skeleton materials.

Eliminating Porosity and Defects

Raw material powders often contain volatile impurities and trapped air.

If these are not removed before the liquid phase forms, they cause foaming or leave behind voids (porosity) in the final product. The vacuum effectively degasses the powder, leading to a denser sintered body with superior retention force on the diamonds.

Critical Process Considerations

While vacuum sintering offers superior results, it introduces specific variables that must be managed to avoid process failure.

Sensitivity to Vacuum Levels

The process relies on the principle that a higher degree of vacuum creates a "neutral" atmosphere.

If the vacuum level fluctuates or is insufficient, elements with high affinity for oxygen (like Manganese) will oxidize immediately. This results in oxide inclusions, which act as weak points within the tool's structure.

The Necessity of Reducing Atmospheres

Vacuum alone is sometimes not enough to remove pre-existing oxide films on metal particles.

Advanced equipment often integrates a reducing atmosphere step alongside the vacuum. This active chemical reduction is required to fully clean the metal surfaces, ensuring the metallurgical bond is not compromised by prior oxidation.

Making the Right Choice for Your Goal

When configuring your sintering process, align your atmospheric controls with your specific performance targets.

- If your primary focus is Cutting Speed (Diamond Sharpness): Prioritize high-vacuum levels to minimize graphitization and keep diamond strength loss below 20%.

- If your primary focus is Tool Longevity (Matrix Durability): Focus on the degassing phase to ensure high density and maximum retention force between the binder and the diamond.

The vacuum atmosphere is not just a passive environment; it is an active processing tool that defines the structural integrity of the final diamond product.

Summary Table:

| Feature | Air Sintering | Vacuum Sintering | Benefit |

|---|---|---|---|

| Diamond Strength Loss | ~35.5% | ~16.6% | Maintains cutting hardness |

| Matrix Oxidation | High | Minimal | Prevents brittle oxide films |

| Material Density | Lower (Porosity) | Higher (Degassed) | Increases tool longevity |

| Bonding Mechanism | Mechanical | Enhanced Wetting | Superior diamond retention |

Maximize Your Tool Performance with KINTEK

Don't let oxidation compromise your diamond tools. KINTEK’s advanced Vacuum Hot Pressing Sintering Furnaces are engineered to eliminate graphitization and maximize bonding density. Backed by expert R&D and manufacturing, we provide customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your laboratory's high-temperature needs.

Contact us today to optimize your sintering process!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What safety features are incorporated into experimental box type atmosphere furnaces? Essential Protections for Hazardous Gas and Heat

- What role do atmosphere furnaces play in the electronics sector? Essential for Semiconductor Fabrication

- What role do atmosphere furnaces play in new energy material R&D? Unlock Precision Synthesis for Batteries and Solar Cells

- What role does the box type annealing atmosphere furnace play in mold manufacturing? Essential for Precision and Durability

- What type of vacuum pumps are used in low vacuum atmosphere furnaces? Reliable Rotary Vane Pumps for Cost-Effective Heating

- What is the function of an industrial resistance furnace in melting Al-Fe-Ni-Sc-Zr alloys? Achieve Alloy Homogeneity

- What challenges are associated with inert atmosphere furnaces? Overcome High Costs and Complexity

- What is the function of a high-temperature pyrolysis furnace in the preparation of magnetic Fe3O4/biochar nanoparticles?