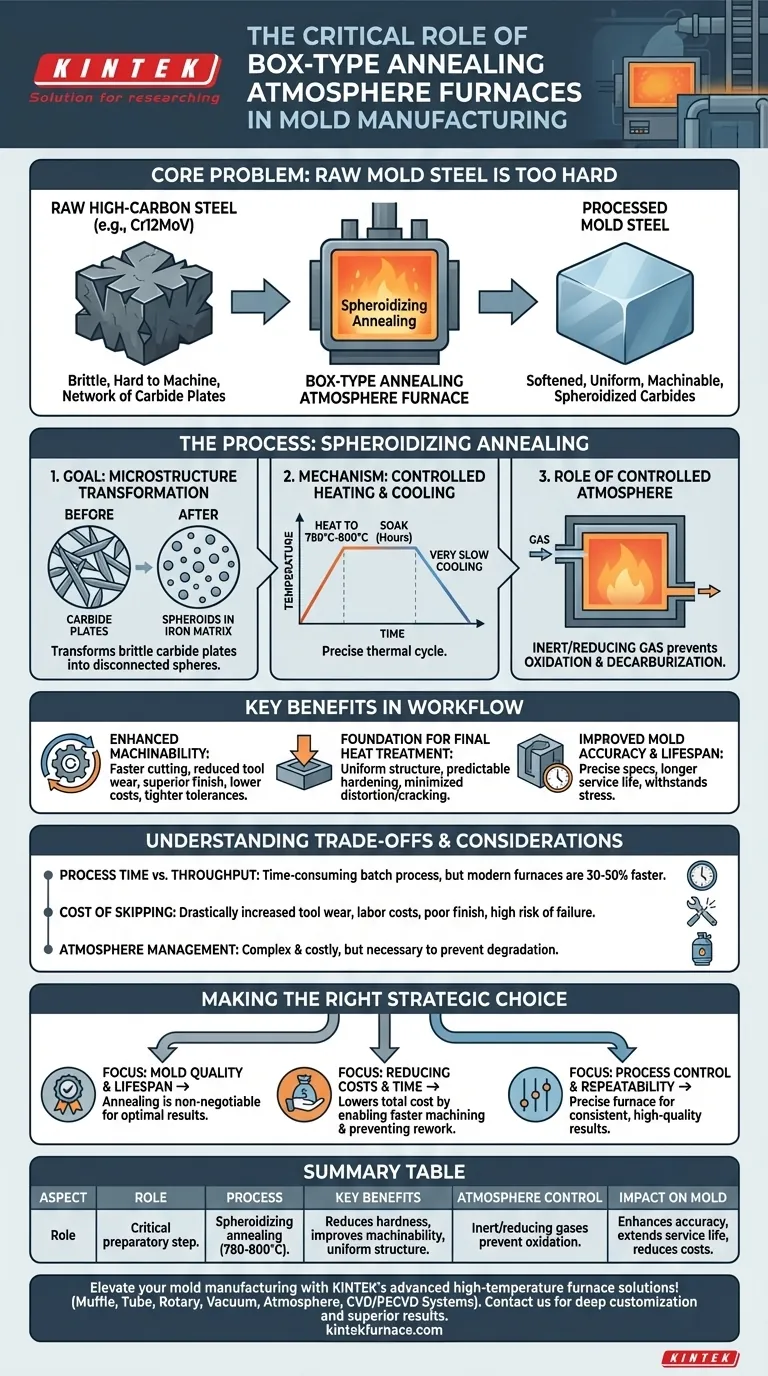

In mold manufacturing, the box-type annealing atmosphere furnace serves a critical, preparatory role. It is used to perform a specific heat treatment called spheroidizing annealing on high-carbon mold steels like Cr12MoV. This controlled process transforms the steel’s internal structure, significantly reducing its hardness and making it easier to machine, which is fundamental to achieving the high precision and extended service life required of a finished mold.

The core problem is that raw mold steel is too hard and brittle for precise, efficient machining. The annealing furnace solves this by fundamentally altering the steel's microstructure, making it softer and more uniform. This isn't just a convenience—it's a foundational step for ensuring the final mold is both dimensionally accurate and durable enough to withstand its operational stresses.

The Core Process: Spheroidizing Annealing

Spheroidizing annealing is a precise thermal cycle designed to optimize the steel's properties for manufacturing. The furnace's role is to execute this cycle with high fidelity.

The Goal: Transforming the Microstructure

The primary objective is to change the shape of the hard carbide elements within the steel. In its initial state, these carbides often exist as a network of sharp, brittle plates.

This process transforms those plates into small, disconnected spheres (or "spheroids") distributed evenly throughout a softer iron matrix. This new structure is what makes the steel significantly less hard and more ductile.

The Mechanism: Controlled Heating and Cooling

The furnace executes a specific temperature profile to achieve this transformation.

The steel is heated to a precise temperature, typically between 780°C and 800°C, and held there for several hours (a "soak").

Following the soak, it is cooled very slowly within the furnace. This slow cooling is critical for allowing the carbides to form into the desired spherical shape.

The Role of the Controlled Atmosphere

The "atmosphere" part of the furnace's name is crucial. At these high temperatures, steel can easily react with oxygen in the air, causing scaling (oxidation) and decarburization (loss of carbon from the surface).

A controlled atmosphere, typically an inert or reducing gas, fills the furnace chamber. This prevents these harmful reactions, preserving the surface quality and chemical integrity of the mold steel.

Key Benefits in the Mold Manufacturing Workflow

This annealing step is not performed in isolation. It has direct, positive impacts on every subsequent stage of mold production and its final performance.

Enhanced Machinability

By significantly reducing the steel's hardness, spheroidizing makes the material much easier to machine. This results in faster cutting speeds, reduced tool wear, and a superior surface finish.

This directly translates to lower manufacturing costs and the ability to achieve tighter dimensional tolerances.

Foundation for Final Heat Treatment

The uniform, refined structure created by annealing is the ideal starting point for the final hardening process (quenching and tempering).

A properly spheroidized structure ensures that the final hardening is consistent and predictable, minimizing the risk of distortion or cracking and maximizing the mold's final strength and wear resistance.

Improved Mold Accuracy and Lifespan

The combination of better machinability and a more reliable final heat treatment leads directly to a higher-quality end product.

The mold can be manufactured to more precise specifications and will have a longer, more predictable service life, capable of withstanding the repeated stresses of injection molding or other forming processes.

Understanding the Trade-offs and Considerations

While essential, integrating this process requires a clear understanding of its implications.

Process Time vs. Throughput

Annealing is inherently a time-consuming process involving slow heating, long soaks, and even slower cooling cycles. This batch process must be factored into production scheduling and can be a bottleneck if not planned correctly.

However, modern furnaces are 30-50% faster than traditional equipment, mitigating this concern significantly.

The Cost of Skipping the Step

The most significant trade-off is choosing not to perform this step. Machining un-annealed steel leads to drastically increased tool wear, higher labor costs, and a poor surface finish.

Furthermore, skipping this step compromises the final heat treatment, leading to a high risk of part distortion, cracking, and a substantially reduced mold lifespan.

Atmosphere Management Complexity

Using a controlled atmosphere is more complex and costly than heating in open air. It requires a reliable supply of specific gases and systems to monitor and maintain the atmosphere's composition.

This added complexity is a necessary trade-off to prevent surface degradation and ensure the material's properties are not compromised during the high-temperature cycle.

Making the Right Choice for Your Goal

The decision to use a box-type annealing atmosphere furnace is strategic, directly influencing quality, cost, and longevity.

- If your primary focus is maximizing mold quality and lifespan: Spheroidizing annealing is a non-negotiable step to ensure optimal machinability and prepare the steel for a successful final heat treatment.

- If your primary focus is reducing manufacturing costs and time: While annealing adds a step, it ultimately lowers total cost by enabling faster machining, minimizing tool wear, and preventing expensive rework or premature mold failure.

- If your primary focus is process control and repeatability: A modern box-type atmosphere furnace provides the precise temperature and atmosphere control essential for consistent, high-quality results across every workpiece.

Ultimately, leveraging a box-type annealing furnace is a strategic investment in the manufacturability and longevity of high-performance molds.

Summary Table:

| Aspect | Role in Mold Manufacturing |

|---|---|

| Process | Performs spheroidizing annealing on high-carbon steels like Cr12MoV |

| Temperature Range | 780°C to 800°C with controlled heating and cooling |

| Key Benefits | Reduces hardness, improves machinability, ensures uniform structure for final heat treatment |

| Atmosphere Control | Uses inert or reducing gases to prevent oxidation and decarburization |

| Impact on Mold | Enhances dimensional accuracy, extends service life, reduces manufacturing costs |

Elevate your mold manufacturing with KINTEK's advanced high-temperature furnace solutions! We specialize in Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by exceptional R&D and in-house manufacturing. Our deep customization capabilities ensure precise spheroidizing annealing processes to meet your unique experimental needs, boosting efficiency and mold longevity. Contact us today to discuss how we can optimize your heat treatment workflows and deliver superior results for your laboratory!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.