In short, low vacuum atmosphere furnaces almost exclusively use mechanical vacuum pumps, with the most common type being the rotary vane pump. These pumps are chosen because they are perfectly suited to the moderate vacuum levels required for these specific industrial processes.

The choice of a vacuum pump is dictated entirely by the furnace's purpose. Low vacuum furnaces are designed for cost-effective processing of materials that do not require extreme purity, making simple and robust mechanical pumps the logical and sufficient choice.

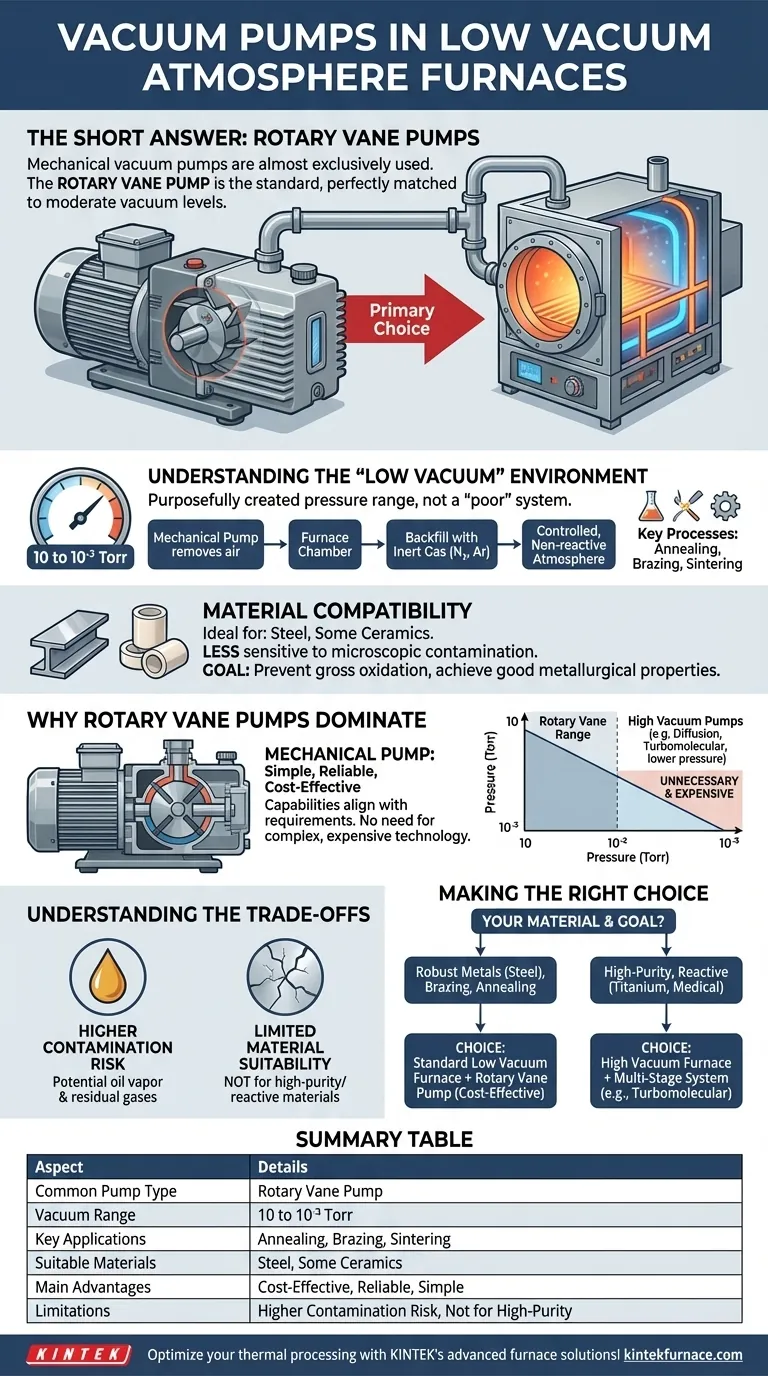

Understanding the "Low Vacuum" Environment

A common point of confusion is the term "low vacuum." It doesn't imply a poor or ineffective system. Instead, it describes a specific range of atmospheric pressure, purposefully created for certain applications.

The Purpose of a Low Vacuum Furnace

Low vacuum furnaces are workhorses for processes like annealing, brazing, and sintering. They are primarily used to reduce the presence of oxygen and other reactive gases.

First, a mechanical pump removes most of the ambient air. Then, the furnace is often backfilled with an inert gas, such as nitrogen or argon, to create a controlled, non-reactive atmosphere for the heating process.

Material Compatibility

This environment is ideal for materials that are less sensitive to microscopic levels of contamination. Common examples include various types of steel and some ceramics.

The goal is to prevent gross oxidation and achieve good metallurgical properties, not to create the ultra-pure conditions needed for reactive metals or semiconductor manufacturing.

Why Rotary Vane Pumps Dominate

The rotary vane pump is the standard for these furnaces because its capabilities align perfectly with the system's requirements. There is no need for more complex or expensive pump technology.

How They Work

Rotary vane pumps are a type of mechanical pump. They operate by trapping a volume of air, compressing it, and expelling it from the system. This is a simple, reliable, and cost-effective mechanism.

Matching Pump to Process

These pumps efficiently bring a furnace chamber down to the "low vacuum" range (typically 10 to 10⁻³ Torr). This is more than sufficient to remove the bulk of the air before an inert gas backfill.

Higher-performance pumps, such as diffusion or turbomolecular pumps, are designed for high or ultra-high vacuum applications. Using them on a low vacuum furnace would be unnecessary, expensive, and offer no practical benefit.

Understanding the Trade-offs

The simplicity and cost-effectiveness of a low vacuum setup come with clear limitations. Recognizing these is critical to avoid process failures.

The Risk of Contamination

Compared to high vacuum systems, low vacuum furnaces present a higher risk of contamination. The mechanical pumps themselves can introduce tiny amounts of oil vapor, and the moderate vacuum level leaves more residual gas molecules behind.

Limited Material Suitability

This inherent contamination risk makes these furnaces unsuitable for high-purity applications. Materials that are highly reactive with oxygen, nitrogen, or carbon, even at very low concentrations, require a high vacuum environment.

Making the Right Choice for Your Process

Your material and desired outcome are the only factors that matter when selecting a furnace and pump system.

- If your primary focus is brazing, annealing, or sintering steel and other robust metals: A standard low vacuum atmosphere furnace with a rotary vane pump is the correct and most cost-effective choice.

- If your primary focus is processing high-purity, reactive, or sensitive materials (like titanium or medical implants): You must use a high vacuum furnace, which requires a multi-stage pumping system (e.g., a rotary vane pump backing a turbomolecular or diffusion pump).

Ultimately, aligning the equipment's capability with the material's sensitivity is the key to successful thermal processing.

Summary Table:

| Aspect | Details |

|---|---|

| Common Pump Type | Rotary Vane Pump |

| Vacuum Range | 10 to 10⁻³ Torr |

| Key Applications | Annealing, Brazing, Sintering |

| Suitable Materials | Steel, Some Ceramics |

| Main Advantages | Cost-Effective, Reliable, Simple Operation |

| Limitations | Higher Contamination Risk, Not for High-Purity Materials |

Optimize your thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, whether for annealing, brazing, or sintering. Contact us today to discuss how our reliable pumps and furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput