The primary function of a vacuum sintering furnace is to provide a strictly controlled high-temperature environment that enables the densification of cemented carbide without chemical degradation. By heating the material under vacuum, the furnace drives the transition from a compacted powder to a solid, high-strength component while preventing oxidation and utilizing heat conduction and radiation to ensure structural uniformity.

Core Insight The vacuum sintering furnace acts as both a thermal reactor and a protective shield. Its ultimate goal is to achieve near-theoretical density in the final product by liquefying the binder phase (cobalt) and removing impurities, all while preventing the material from reacting adversely with oxygen or atmospheric gases.

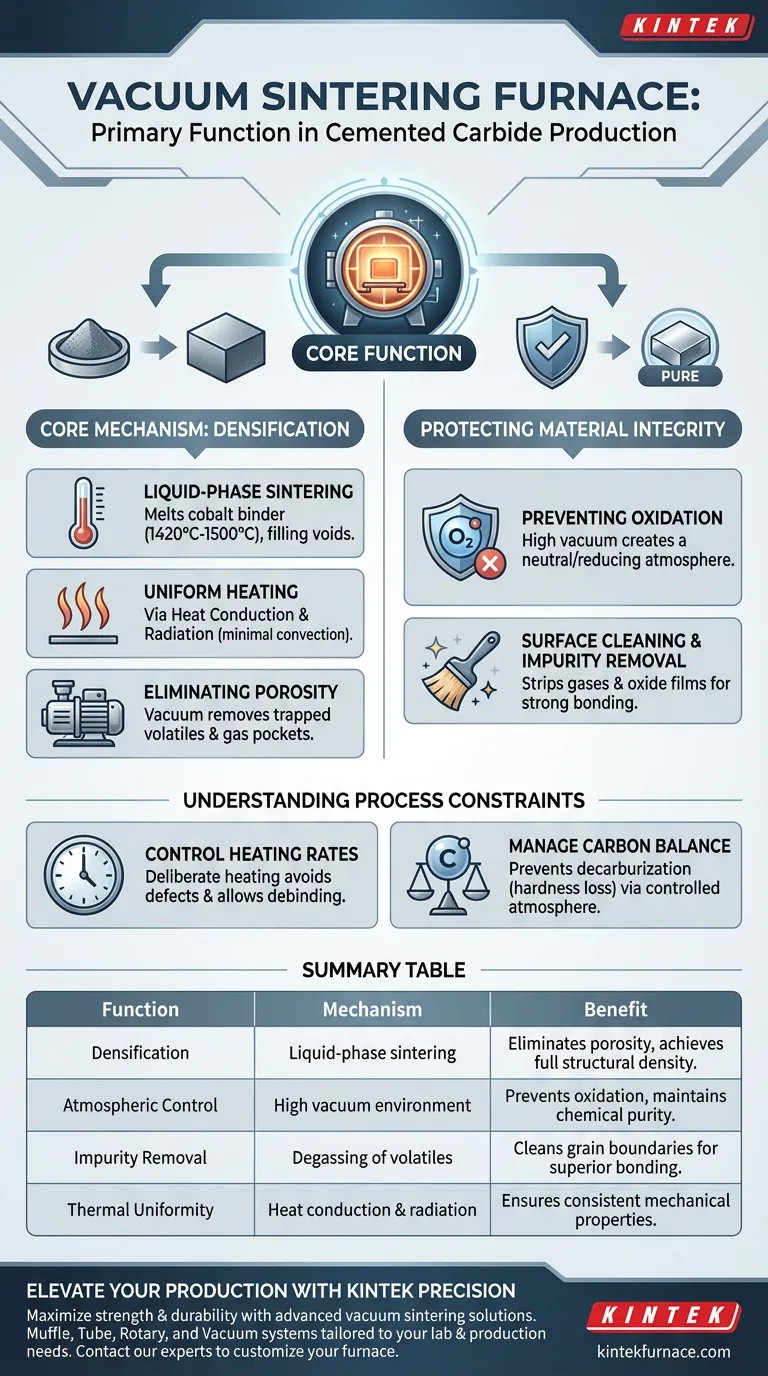

The Core Mechanism: Densification

The central purpose of the furnace is to facilitate the physical transformation of the material structure. This is achieved through precise thermal regulation and atmospheric control.

Achieving Liquid-Phase Sintering

The furnace raises temperatures to critical levels (typically between 1420°C and 1500°C), causing the cobalt binder phase to melt. This liquid phase wets the tungsten carbide grains, filling the voids between particles through capillary action to create a solid, non-porous mass.

Utilizing Heat Transfer Modes

To ensure the material heats evenly, the furnace relies on heat conduction and radiation, with minimal convection due to the vacuum environment. This controlled heating profile is essential for maintaining uniform properties throughout the cemented carbide part.

Eliminating Porosity

The vacuum environment plays an active role in densification by lowering the boiling point of trapped volatiles. The low pressure helps remove gas pockets from the powder compact, ensuring the final alloy reaches a densification level close to its theoretical limit.

Protecting Material Integrity

Beyond simple heating, the vacuum furnace serves a critical chemical function. It preserves the purity of the cemented carbide, which is directly linked to its mechanical performance.

Preventing Oxidation

High temperatures usually accelerate oxidation, which degrades cemented carbide. The furnace creates a neutral or reducing atmosphere (high vacuum) that prevents oxygen from reacting with the tungsten carbide or cobalt, ensuring the material retains its designed chemical composition.

Surface Cleaning and Impurity Removal

The vacuum environment effectively strips adsorbed gases and oxide films from the surface of the powder particles. Clean particle surfaces are a prerequisite for strong bonding at the grain boundaries, which dictates the final strength and toughness of the tool.

Understanding Process Constraints

While vacuum sintering is effective, it requires careful management of physical and chemical trade-offs to avoid defects.

Controlling Heating Rates

The application of heat must be deliberate; a very slow heating rate (e.g., 0.2 °C/min) is often required during the initial stages to gently remove residual binders. Rapid heating during the wrong phase can lead to structural defects or incomplete debinding.

Managing Carbon Balance

While the vacuum prevents oxidation, the environment must also prevent decarburization (loss of carbon). If the atmosphere is not perfectly controlled—sometimes utilizing specific container environments like graphite—the tungsten carbide phase can degrade, ruining the material's hardness.

Making the Right Choice for Your Goal

To maximize the utility of a vacuum sintering furnace, align your process parameters with your specific quality targets.

- If your primary focus is mechanical strength: Prioritize a process that ensures clean grain boundaries by maintaining a high vacuum to remove all oxide films before the liquid phase begins.

- If your primary focus is full densification: Ensure the furnace can reach and hold the optimal temperature (approx. 1450°C) to allow adequate flow of the liquid cobalt phase into all particle gaps.

By strictly controlling the vacuum and temperature profile, you ensure the cemented carbide meets the rigorous design specifications required for high-performance industrial applications.

Summary Table:

| Function | Mechanism | Benefit to Cemented Carbide |

|---|---|---|

| Densification | Liquid-phase sintering (1420°C - 1500°C) | Eliminates porosity and achieves full structural density. |

| Atmospheric Control | High vacuum environment | Prevents oxidation and maintains chemical purity of the alloy. |

| Impurity Removal | Degassing of volatiles | Cleans grain boundaries for superior bonding strength. |

| Thermal Uniformity | Heat conduction and radiation | Ensures consistent mechanical properties throughout the part. |

Elevate Your Carbide Production with KINTEK Precision

Maximize the strength and durability of your industrial components with KINTEK’s advanced vacuum sintering solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, and Vacuum sintering systems tailored to your specific material requirements. Whether you need near-theoretical densification or precise atmospheric control, our systems are fully customizable to meet your unique lab and production needs.

Ready to optimize your high-temperature processes? Contact our experts today to find the perfect furnace for your application.

Visual Guide

References

- Mao Li, Hesong Li. Numerical simulation of the heating process in a vacuum sintering electric furnace and structural optimization. DOI: 10.1038/s41598-024-81843-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Is vacuum brazing better than brazing? Unlock Superior Joint Quality for Critical Applications

- What are the main types of vacuum furnaces? Choose the Right Type for Your Heat Treatment Needs

- What modular features enhance vacuum furnace flexibility? Boost Efficiency with Scalable, Quick-Change Designs

- What are the key design features of a vacuum furnace? Optimize Your High-Temperature Material Processing

- What is Age Hardening in vacuum heat treating? Unlock Peak Metal Performance with Precision

- What processes are hot wall vacuum furnaces used for? Ideal for precise, uniform low-temperature heat treatments

- What environmental controls does a vacuum diffusion furnace provide? Master High-Vacuum Heat Treatment

- What types of materials and processes are compatible with vacuum furnaces? Achieve Purity and Precision in Heat Treatment