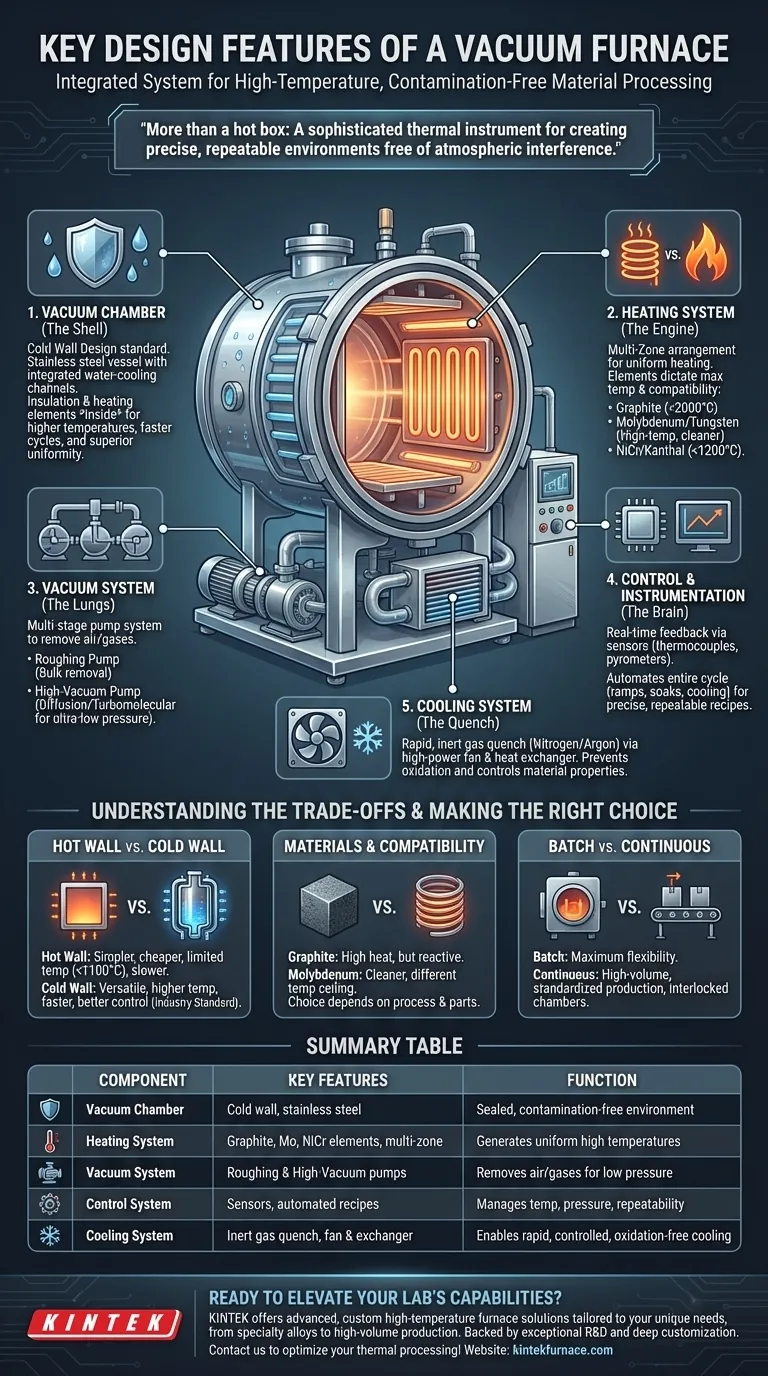

At its core, a vacuum furnace is an integrated system designed for high-temperature material processing in a controlled, contamination-free environment. The key design features are the vacuum chamber, heating system, vacuum pump system, temperature control system, and cooling system, all working in unison to manipulate material properties with extreme precision.

A vacuum furnace is not simply a box that gets hot. It is a sophisticated thermal processing instrument where every component—from the chamber wall to the control software—is engineered to create and maintain a highly specific, repeatable environment free of atmospheric interference.

Deconstructing the Core Components

A vacuum furnace's capabilities are defined by the design and integration of its primary systems. Understanding each one reveals how the furnace achieves its results.

The Vacuum Chamber (The Shell)

The chamber is the sealed vessel that contains the entire process. It is typically constructed from durable materials like stainless steel to withstand the pressure differential and high temperatures.

There are two fundamental design philosophies for the chamber: hot wall and cold wall. While hot wall designs exist, the vast majority of modern, high-performance furnaces use a cold wall design.

In a cold wall furnace, the outer vessel remains cool via integrated water-cooling channels. The insulation and heating elements are located inside the chamber, allowing for much higher operating temperatures, faster heating and cooling cycles, and superior temperature uniformity.

The Heating System (The Engine)

This system generates the thermal energy for the process. The choice of heating elements is critical as it directly dictates the furnace's maximum operating temperature and chemical compatibility.

Common heating elements include:

- Graphite: Used for very high temperatures, often exceeding 2000°C.

- Molybdenum and Tungsten: Refractory metals used for high-temperature applications where carbon is undesirable.

- Nickel-Chrome (NiCr) or Kanthal (FeCrAl) wire: Used for lower temperature applications, typically below 1200°C.

The heating elements are arranged in multiple "zones" within the chamber, each independently controlled to ensure the workpiece is heated uniformly from all sides.

The Vacuum System (The Lungs)

This is not a single pump but a system of pumps working in stages to remove air and other gases from the chamber. It begins with a mechanical "roughing" pump to remove the bulk of the air.

A secondary high-vacuum pump, such as a diffusion pump or turbomolecular pump, then takes over to achieve the extremely low pressures required for processing. The entire system is connected by a series of valves that allow the controller to precisely manage the vacuum level.

The Control & Instrumentation System (The Brain)

This is the central nervous system of the furnace. It uses sensors, such as thermocouples or high-temperature infrared pyrometers, to get real-time feedback on the process conditions.

The control system automates the entire cycle according to a pre-programmed recipe, managing the evacuation rate, heating ramps, soak times at specific temperatures, and the final cooling or quenching sequence. This ensures repeatability and precision.

The Cooling System (The Quench)

Controlled cooling is just as important as heating for achieving desired material properties like hardness. Most vacuum furnaces use an inert gas, such as nitrogen or argon, for rapid cooling.

The system backfills the chamber with the gas, which is then circulated by a high-power fan through a heat exchanger. This allows for a fast, uniform quench without exposing the hot material to oxygen. A separate water-cooling circuit is always present to protect the furnace body, seals, and power feedthroughs from overheating.

Understanding the Trade-offs

The final design of a vacuum furnace is a series of engineering compromises tailored to a specific set of applications.

Hot Wall vs. Cold Wall Design

A hot wall furnace has heating elements outside the vacuum chamber, heating the vessel itself. This design is simpler and cheaper but is limited in temperature (typically <1100°C) and has slower heating/cooling cycles.

A cold wall furnace, as described earlier, is far more versatile. It offers higher temperatures, faster cycles, and better control, making it the standard for demanding processes like brazing, sintering, and heat treatment.

Heating Element and Insulation Materials

The choice of heating element and internal insulation (often graphite felt or ceramic fiber) is a critical trade-off. Graphite is excellent for high heat but can react with certain metals. Molybdenum is cleaner for some processes but has a different temperature ceiling and cost profile. The materials must be chosen based on the process temperature and chemical compatibility with the parts being treated.

Batch vs. Continuous Processing

Most vacuum furnaces are batch furnaces, where a single load (or "charge") is processed at a time. This provides maximum flexibility. For high-volume, standardized production, continuous furnaces exist, which use a series of interlocked chambers to move parts through the heating and cooling zones without breaking the vacuum.

Making the Right Choice for Your Goal

When specifying or selecting a vacuum furnace, your primary application dictates the necessary design features.

- If your primary focus is maximum temperature and performance: Prioritize a cold-wall design with graphite or refractory metal heating elements and a multi-zone temperature control system.

- If your primary focus is processing specialty alloys or reactive materials: Scrutinize the chemical compatibility of the heating elements and insulation; a "clean" furnace with molybdenum elements may be required over graphite.

- If your primary focus is high-volume production: Evaluate continuous furnace designs and the power of the gas quenching system to minimize cycle time.

Understanding these core design principles empowers you to select and operate a vacuum furnace to achieve precise and repeatable material transformations.

Summary Table:

| Component | Key Features | Function |

|---|---|---|

| Vacuum Chamber | Cold wall design, stainless steel construction | Sealed vessel for contamination-free environment |

| Heating System | Graphite, molybdenum, or NiCr elements, multi-zone control | Generates uniform high temperatures |

| Vacuum System | Roughing and high-vacuum pumps (e.g., diffusion, turbomolecular) | Removes air and gases to achieve low pressures |

| Control System | Sensors (thermocouples, pyrometers), automated recipes | Manages temperature, pressure, and cycle repeatability |

| Cooling System | Inert gas quench (e.g., nitrogen), fan and heat exchanger | Enables rapid, controlled cooling without oxidation |

Ready to elevate your lab's capabilities with a custom vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're processing specialty alloys or aiming for high-volume production, our expertise ensures precise, repeatable results. Contact us today to discuss how we can optimize your thermal processing workflows!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- What are the primary application fields for box furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures