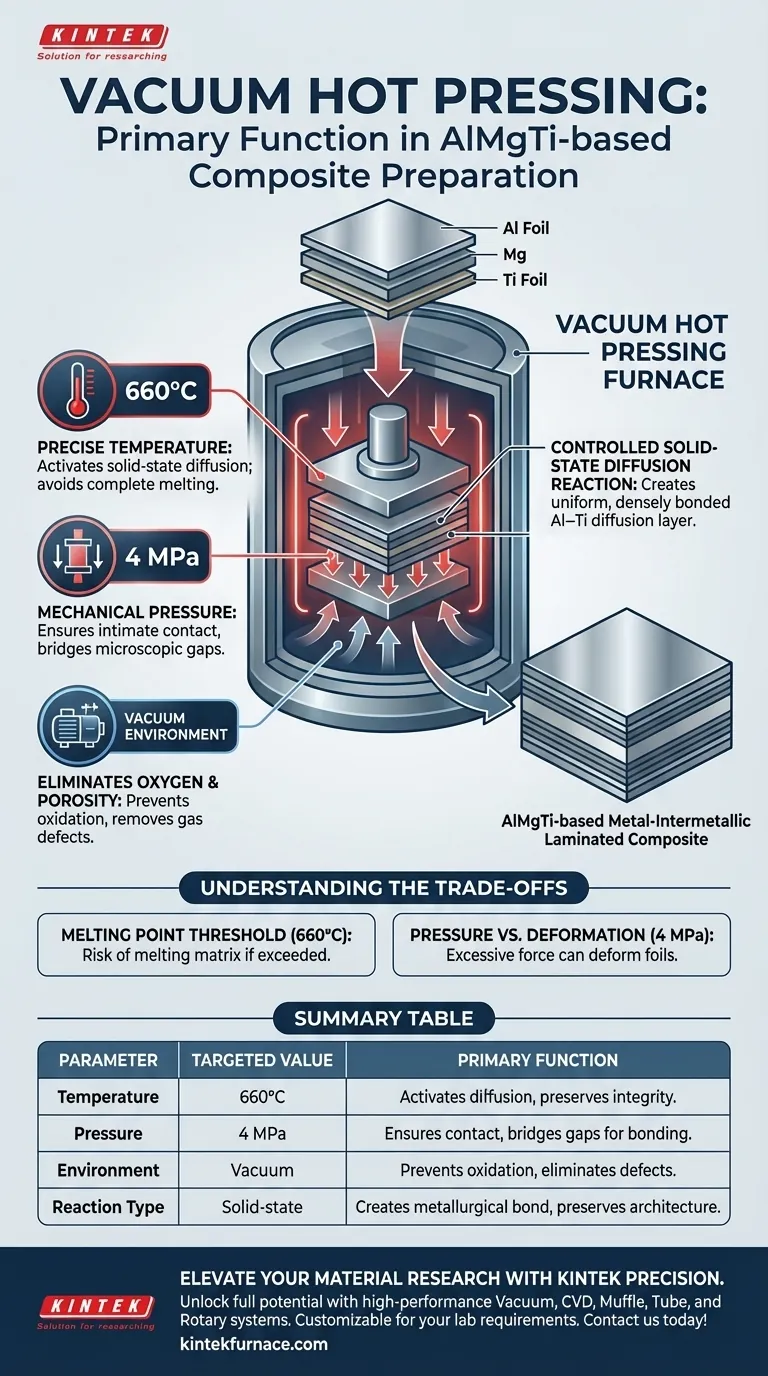

The primary function of the vacuum hot pressing furnace in the first preparation step of AlMgTi-based composites is to facilitate a controlled solid-state diffusion reaction between Aluminum and Titanium foils. By maintaining a specific environment of 660°C and 4 MPa, the equipment generates a uniform, densely bonded Al-Ti diffusion layer while preventing the matrix from completely melting.

The core challenge in this process is creating a metallurgical bond without destroying the layered architecture. The vacuum hot pressing furnace solves this by driving atomic diffusion at the precise threshold where bonding occurs, but structural integrity is preserved.

Driving the Solid-State Reaction

Precise Temperature Control

The furnace maintains a critical temperature of 660°C. This specific thermal setpoint is chosen to activate the diffusion mechanism between the metal foils.

It ensures the reaction proceeds efficiently but remains low enough to avoid the complete melting of the matrix. This balance is essential for retaining the intended laminated structure of the composite.

The Role of Mechanical Pressure

Simultaneously, the furnace applies a moderate mechanical pressure of 4 MPa. This pressure forces the Aluminum and Titanium layers into intimate physical contact.

This contact is necessary to bridge microscopic gaps between the foils. It reduces the diffusion distance, allowing atoms to migrate across the interface to form a continuous Al-Ti layer.

Ensuring Material Integrity

Preventing Oxidation

Both Aluminum and Titanium are highly reactive metals that oxidize rapidly at elevated temperatures. The vacuum environment is the critical control factor that isolates these materials from oxygen.

By eliminating oxygen, the furnace prevents the formation of brittle oxide layers on the foil surfaces. This ensures that the diffusion occurs across a clean metallic interface, resulting in a high-quality metallurgical bond.

Eliminating Porosity

The combination of vacuum and pressure serves to remove defects from the composite. The vacuum aids in exhausting residual gases trapped between the stacked layers before compression.

Concurrently, the applied pressure collapses internal voids. This dual action results in a dense, non-porous intermetallic compound layer that is free from gas defects.

Understanding the Trade-offs

The Melting Point Threshold

Operating at 660°C places the process very close to the melting point of Aluminum. If the temperature control drifts significantly higher, the matrix will melt, destroying the laminated structure.

Pressure vs. Deformation

While pressure is required for bonding, excessive force can lead to unwanted plastic deformation of the foils. The 4 MPa parameter is a calculated moderate pressure: high enough to bond, but low enough to maintain layer thickness uniformity.

Making the Right Choice for Your Goal

To optimize the preparation of AlMgTi-based composites, consider your specific structural requirements:

- If your primary focus is Interface Quality: Ensure your vacuum system can maintain a high-vacuum state (e.g., 10^-3 Pa) to strictly prevent oxidation and ensure clean atomic diffusion.

- If your primary focus is Structural Precision: Prioritize thermal stability in your equipment to ensure the temperature holds at 660°C without overshooting into a full melt state.

The success of this preparation step relies entirely on the furnace's ability to balance thermal energy with mechanical restraint in an oxygen-free environment.

Summary Table:

| Parameter | Targeted Value | Primary Function in Process |

|---|---|---|

| Temperature | 660°C | Activates solid-state diffusion while preserving matrix integrity. |

| Pressure | 4 MPa | Ensures intimate contact and bridges microscopic gaps for bonding. |

| Environment | Vacuum | Prevents oxidation and eliminates porosity/gas defects. |

| Reaction Type | Solid-state | Creates a metallurgical bond without destroying layered architecture. |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your AlMgTi-based composites with high-performance vacuum systems. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum, CVD, Muffle, Tube, and Rotary systems, all fully customizable to meet your specific laboratory requirements.

Whether you need precise thermal stability to prevent matrix melting or high-vacuum integrity for clean atomic diffusion, our team is ready to deliver the perfect solution for your high-temperature applications. Contact us today to discuss your unique needs and get a custom quote!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the function of a Hot Press Sintering (HPS) furnace? Mastering High-Density Ceramics for PCFC

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- What industrial applications utilize vacuum hot press furnaces? Essential for Aerospace, Medical, and Electronics

- Why is graphite mold interaction critical for ZnS ceramics? Protect Your Optical Purity in Vacuum Hot Pressing

- What is the difference between hot pressing and sintering? Choose the Right Process for Your Materials

- What is the primary function of graphite foil within the FAST system? Optimize Your Sintering and Tooling Protection

- What types of materials can be processed using vacuum hot press furnaces? Ideal for Advanced Ceramics and Metals

- What role does 30 MPa pressure play in SiC/Cu-Al2O3 sintering? Achieve 97.6% Density with Vacuum Hot Pressing