The primary function of a Chemical Vapor Deposition (CVD) system in the synthesis of Fe/MWCNT nanostructures is to orchestrate the precise loading or encapsulation of iron-based nanoparticles onto multi-walled carbon nanotubes (MWCNTs). It achieves this by creating a strictly controlled high-temperature environment where gas-phase precursors undergo specific chemical reactions to form solid composite interfaces.

By acting as a high-precision furnace, the CVD system facilitates the growth of iron-based nanostructures directly onto carbon nanotubes, a process critical for creating composite materials with superior electrocatalytic activity.

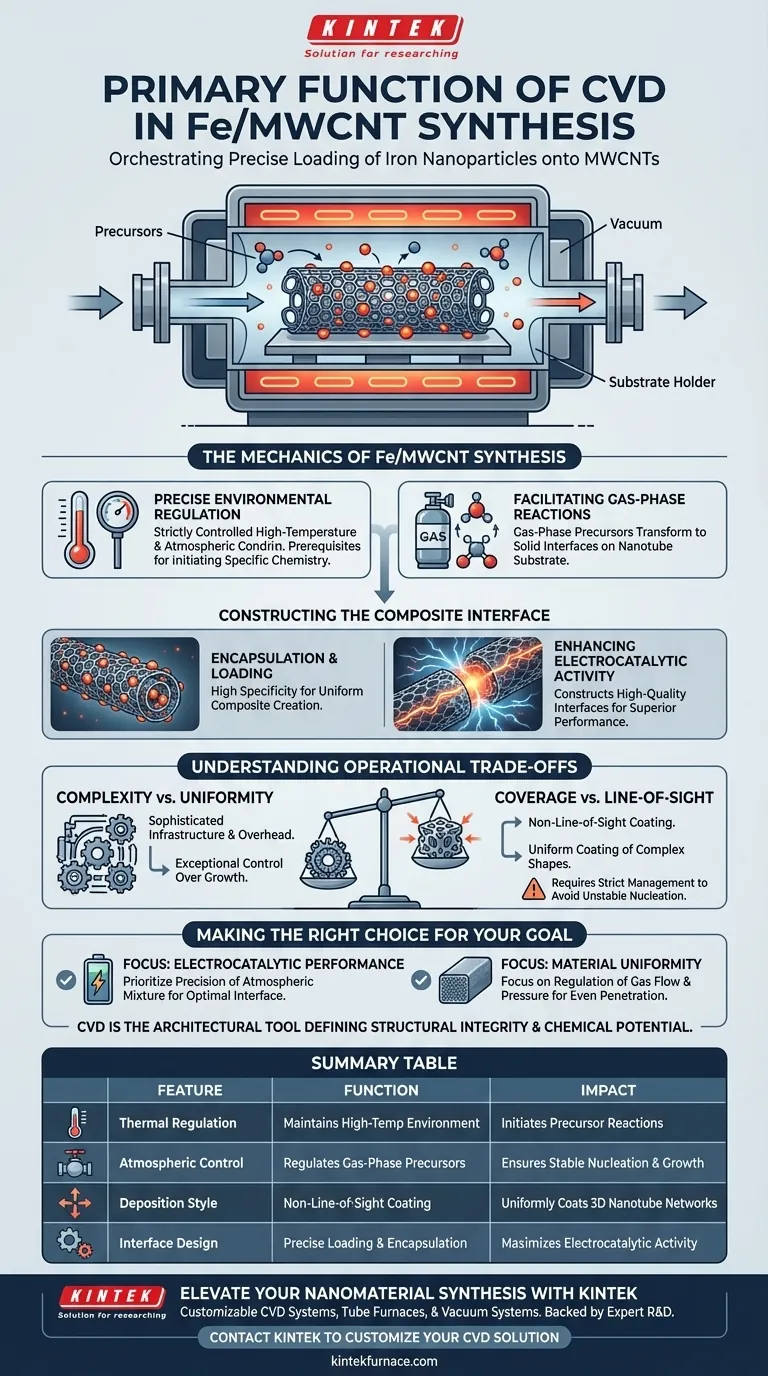

The Mechanics of Fe/MWCNT Synthesis

Precise Environmental Regulation

The CVD system provides the foundational conditions necessary for nanostructure growth. It maintains a strictly controlled high-temperature environment within a reaction furnace.

Simultaneously, it regulates the atmospheric conditions inside the chamber. This dual control of heat and atmosphere is the prerequisite for initiating the specific chemistry required to modify MWCNTs.

Facilitating Gas-Phase Reactions

The core mechanism involves the transformation of matter states. The system introduces gas-phase precursors into the reaction chamber.

Under the regulated thermal conditions, these gases react chemically. This reaction converts the precursors into solid substances that deposit directly onto the substrate—in this case, the multi-walled carbon nanotubes.

Constructing the Composite Interface

Encapsulation and Loading

The CVD process allows for high specificity in how materials combine. It enables the precise loading of iron nanoparticles onto the surface of the MWCNTs.

Alternatively, depending on the parameters used, it can facilitate the encapsulation of these iron-based particles within the nanotube structure. This precision is vital for creating a uniform composite rather than a simple mixture.

Enhancing Electrocatalytic Activity

The ultimate goal of this synthesis is functional performance. By successfully integrating iron nanoparticles with MWCNTs, the CVD system constructs high-quality material interfaces.

These engineered interfaces are directly responsible for the resulting material's high electrocatalytic activity. The CVD system ensures that the chemical connection between the iron and the carbon is robust and chemically active.

Understanding Operational Trade-offs

Complexity vs. Uniformity

While CVD provides exceptional control over nanostructure growth, it requires a complex infrastructure. The system relies on sophisticated components, including vacuum pumps, mass flow controllers, and precise heating elements, which increases operational overhead.

Coverage vs. Line-of-Sight

A major advantage of CVD is that it is a non-line-of-sight process. This allows the gas-phase precursors to coat complex, three-dimensional shapes like porous nanotube networks uniformly, a feat difficult to achieve with physical deposition methods.

However, this requires strict management of gas flow and pressure. If the precursor gas flow or furnace temperature fluctuates, nucleation kinetics can become unstable, potentially compromising the uniformity of the iron loading.

Making the Right Choice for Your Goal

To maximize the effectiveness of a CVD system for Fe/MWCNT synthesis, align your process parameters with your specific material requirements.

- If your primary focus is Electrocatalytic Performance: Prioritize the precision of the atmospheric mixture to ensure optimal interface construction between the iron and the MWCNTs.

- If your primary focus is Material Uniformity: Focus on the regulation of gas flow and pressure to ensure the precursors penetrate and coat the nanotube network evenly.

The CVD system is not just a heating element; it is the architectural tool that defines the structural integrity and chemical potential of your final nanocomposite.

Summary Table:

| Feature | Function in Fe/MWCNT Synthesis | Impact on Final Material |

|---|---|---|

| Thermal Regulation | Maintains high-temperature environment | Initiates precursor chemical reactions |

| Atmospheric Control | Regulates gas-phase precursors | Ensures stable nucleation and growth |

| Deposition Style | Non-line-of-sight coating | Uniformly coats 3D nanotube networks |

| Interface Design | Precise loading & encapsulation | Maximizes electrocatalytic activity |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is the difference between a simple mixture and a high-performance composite. KINTEK provides industry-leading CVD systems, Tube furnaces, and Vacuum systems designed to give you absolute control over temperature and atmospheric conditions.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet the unique needs of researchers developing Fe/MWCNT nanostructures and other advanced materials. Partner with us to ensure robust chemical interfaces and superior material uniformity in every run.

Contact KINTEK Today to Customize Your CVD Solution

Visual Guide

References

- Vivek Kumar, Rajnish Dhiman. Fe/MWCNT Nanostructures Synthesized via CVD for Enhanced Electrocatalytic Performance in Zinc‐Air Batteries. DOI: 10.1002/admt.202500539

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the advantages of using KI as a growth promoter for VSe2 crystals? Achieve Large, Atomically Thin Nanosheets

- What are the advantages of CVD over PVD? Superior Conformality for Complex Shapes

- What is the role of a vertical tube FCCVD system? Scalable High-Volume Synthesis of SWCNTs

- What are the key characteristics of a CVD coating process? Unlock Superior Adhesion and Complex Coating

- Why must a CVD system use high-precision MFCs? Achieve Atomic Perfection in Your Material Synthesis

- How does a high-precision MFC affect MoS2 growth? Mastering Epitaxial Quality in CVD

- What roles do high-purity Argon (Ar) and Hydrogen (H2) play as carrier gases in APCVD for optimal crystal growth?

- What is the role of Chemical Vapor Deposition (CVD) systems in manufacturing? Unlock Atomic-Level Precision for Advanced Materials