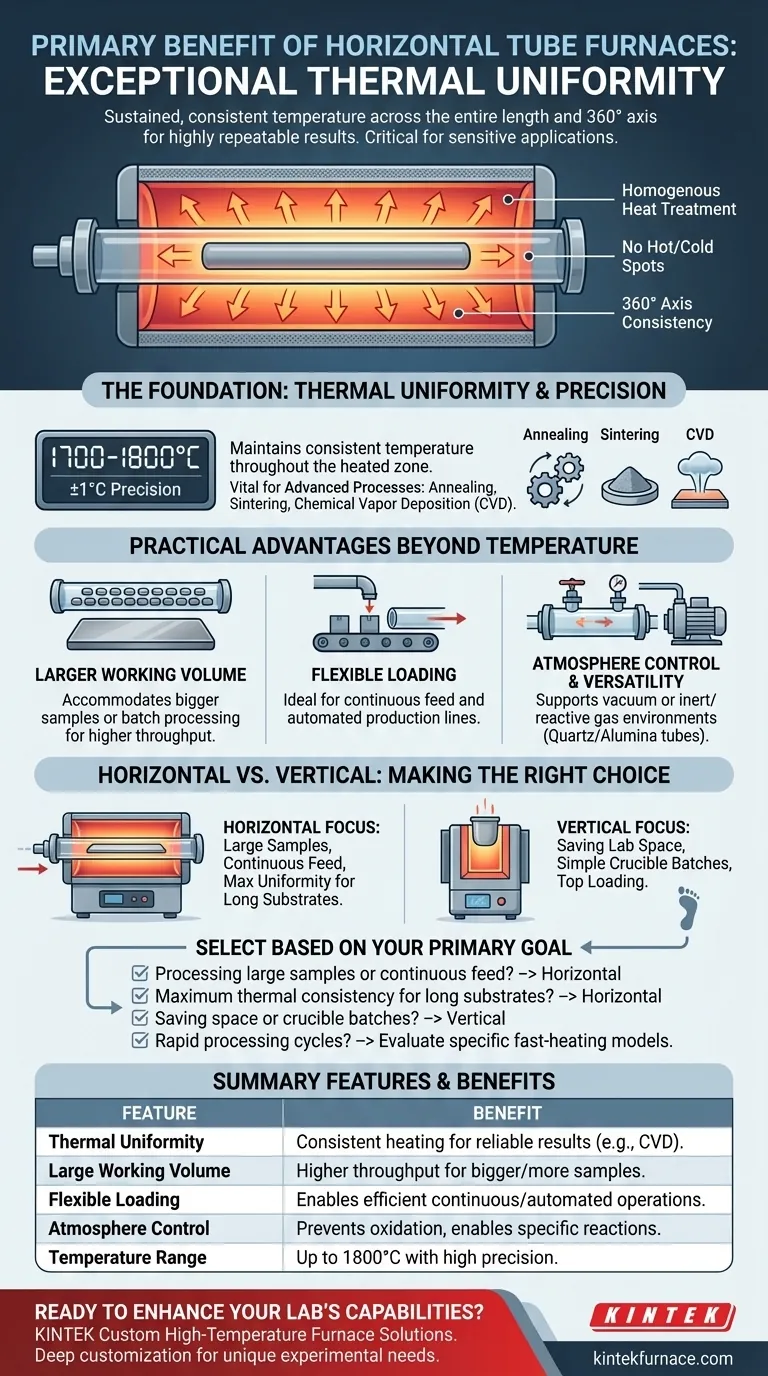

At their core, horizontal tube furnaces are most valued for their exceptional thermal uniformity. These systems are engineered to subject a workpiece to a sustained, consistent temperature across its entire length and 360° axis, ensuring highly repeatable and reliable material processing. This precision is critical for sensitive applications requiring homogenous heat treatment.

While exceptional thermal uniformity is the primary technical benefit, the practical choice between a horizontal and vertical furnace truly depends on your process requirements, including sample size, loading method, and laboratory space.

The Foundation of Performance: Thermal Uniformity

The defining characteristic of a high-quality tube furnace is its ability to create a stable, uniform thermal environment. Horizontal designs excel in this area for several key reasons.

What is Thermal Uniformity?

Thermal uniformity refers to the furnace's ability to maintain a consistent temperature throughout the heated zone where the sample is placed.

A heating element, which typically surrounds the processing tube, is designed to distribute heat evenly along the sample's entire length. This prevents "hot spots" or "cold spots" that can compromise results.

Why Uniformity is Critical

For many advanced processes, precise and consistent heating is not just a benefit—it is a requirement.

Processes like annealing, sintering, and Chemical Vapor Deposition (CVD) rely on uniform temperatures to ensure the final material has the desired properties. Inconsistent heating can lead to defects, structural weaknesses, or failed experiments.

Achieving Precise Control

Modern horizontal tube furnaces offer more than just general uniformity. They provide exacting control.

They are capable of maintaining temperatures up to 1700-1800°C with a precision of ±1°C. This level of accuracy is what enables the reliable synthesis and processing of advanced metals, ceramics, and nanomaterials.

Practical Advantages Beyond Temperature

While uniformity is the key technical strength, horizontal furnaces offer other significant operational advantages that make them suitable for a wide range of applications.

Larger Working Volume

The horizontal orientation naturally accommodates longer processing tubes. This translates to a larger working volume, allowing for the processing of bigger samples or a greater number of smaller samples in a single batch.

Flexible Loading for Continuous Processing

The horizontal layout is ideal for processes that require a continuous feed of material. Samples can be easily pushed or pulled through the tube, making these furnaces well-suited for automated or semi-automated production lines.

Material Versatility and Atmosphere Control

These furnaces can be fitted with tubes made from various materials, such as quartz or alumina, depending on the temperature and chemical requirements of the process.

They are also easily adapted for controlled-atmosphere processing, allowing for work to be done in a vacuum or with specific inert or reactive gases, which is vital for preventing oxidation or enabling specific chemical reactions.

Understanding the Trade-offs: Horizontal vs. Vertical

To make an informed decision, you must compare the horizontal furnace to its vertical counterpart. Both have claims to uniformity, but their core strengths are suited to different tasks.

The Uniformity Debate

Both horizontal and vertical furnaces are designed to provide excellent temperature distribution along the length of the tube.

A horizontal furnace is often superior for ensuring uniformity across a very long, flat workpiece. In a vertical furnace, factors like gravity can cause powders to compact, potentially altering heat transfer, though they are excellent for processing samples in crucibles.

Sample Handling and Footprint

Vertical furnaces offer a significant advantage for saving lab space due to their smaller footprint. Their top-loading design can also simplify batch processing for samples contained in crucibles.

In contrast, horizontal furnaces are easier to load with long substrates or "boats" containing multiple samples. This orientation is almost always required for any continuous or semi-continuous process.

Heating and Cooling Rates

While not exclusive to one type, many modern furnace designs emphasize rapid heating and cooling cycles. This capability can significantly shorten production time and reduce thermal stress on the material, improving the quality of the final product.

Making the Right Choice for Your Application

Selecting the right furnace requires moving beyond a single feature and analyzing your specific goals.

- If your primary focus is processing large samples or a continuous material feed: The geometry and larger volume of a horizontal tube furnace make it the superior choice.

- If your primary focus is maximum thermal consistency for long substrates: A horizontal furnace provides exceptional, reliable heat distribution along the entire length of the workpiece.

- If your primary focus is saving laboratory space or simple batch processing in crucibles: A vertical furnace is often more convenient and space-efficient.

- If your primary focus is rapid processing cycles: Evaluate specific models of either type that advertise fast heating and cooling rates to minimize production time.

Ultimately, understanding these fundamental trade-offs ensures you select not just a furnace, but the correct tool for your specific scientific or industrial goal.

Summary Table:

| Feature | Benefit |

|---|---|

| Thermal Uniformity | Ensures consistent heating for reliable results in processes like annealing and CVD |

| Large Working Volume | Accommodates bigger samples or batch processing for higher throughput |

| Flexible Loading | Enables continuous feed and automation for efficient operations |

| Atmosphere Control | Supports vacuum or gas environments to prevent oxidation and enable reactions |

| Temperature Range | Up to 1800°C with ±1°C precision for advanced material synthesis |

Ready to enhance your lab's capabilities with a custom high-temperature furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Horizontal Tube, Muffle, Vacuum, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior thermal uniformity and efficiency. Contact us today to discuss how we can support your material processing goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability