A successful MPCVD maintenance strategy is a systematic, multi-layered approach grounded in preventative action rather than reactive repair. It involves regular, meticulous checks of critical subsystems—primarily the gas delivery, cooling, vacuum, and microwave components—performed by trained personnel. This ensures the equipment operates within its precise specifications, which is essential for both safety and the quality of material deposition.

The core purpose of MPCVD maintenance is not simply to keep the machine running. It is to create an exceptionally stable and pure processing environment, as even minor deviations in temperature, pressure, or gas purity can drastically compromise the outcome of a growth cycle.

The Foundation: A Proactive and Systemized Approach

Relying on fixing problems as they arise is a recipe for inconsistent results, extended downtime, and increased operational costs. A proactive maintenance schedule is the only way to ensure the stable, repeatable conditions that high-quality material synthesis demands.

Why Ad-Hoc Maintenance Fails

Reactive maintenance, or "firefighting," means you are always behind. A seemingly minor issue, like a small water leak or a dirty gas line, can contaminate a multi-day growth run, wasting significant time, resources, and high-purity gases.

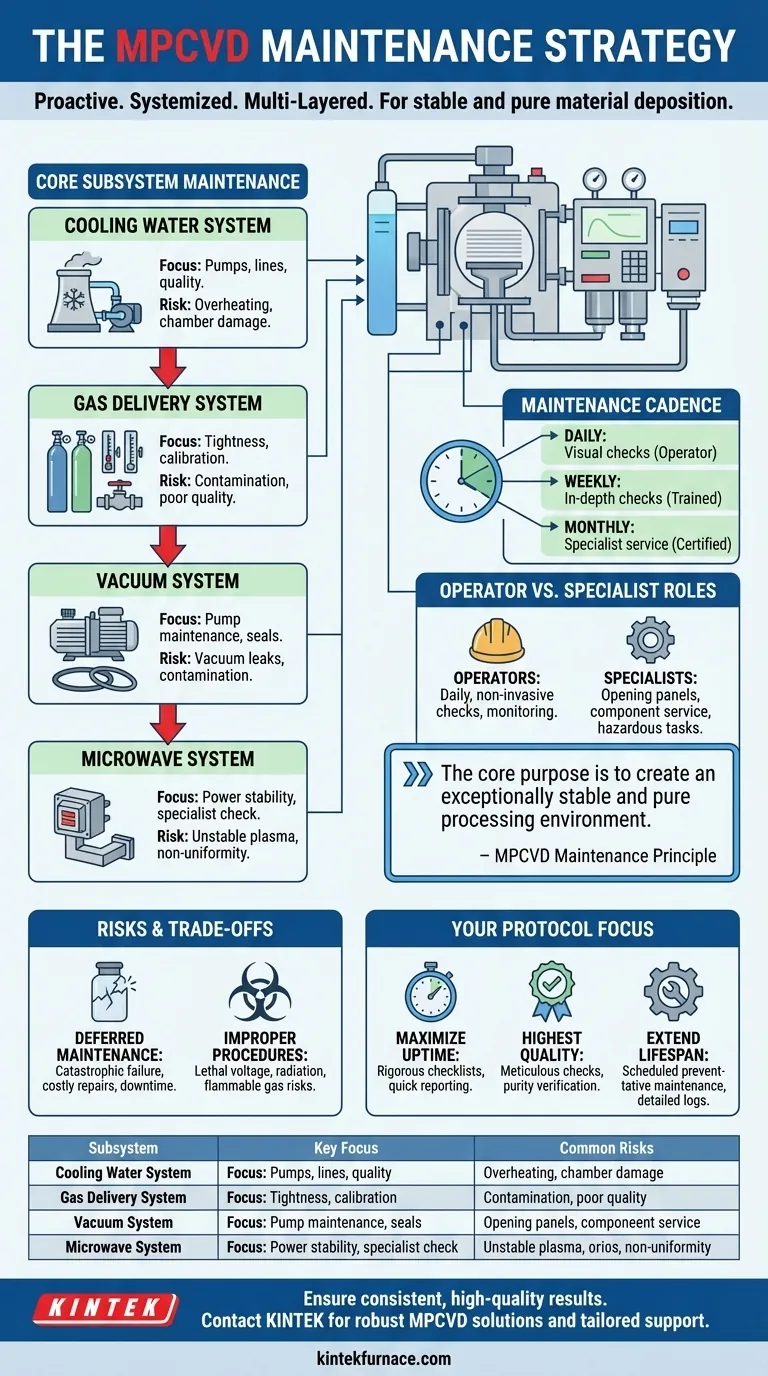

Establishing a Maintenance Cadence

A robust strategy divides tasks into daily, weekly, and monthly schedules. Daily checks are typically visual inspections performed by operators, while more in-depth service is scheduled less frequently and handled by trained technicians.

Operator vs. Specialist Roles

Due to the system's complexity involving high voltage, microwaves, and flammable gases, a clear distinction must be made.

- Operators should be trained for daily, non-invasive checks (e.g., monitoring pressure gauges, checking for visible leaks, listening for unusual pump noises).

- Specialists or certified technicians must perform any task that involves opening panels, servicing components, or working directly with electrical or gas hardware.

Core System Maintenance Breakdown

An MPCVD system is an integration of several critical subsystems. Each one must function perfectly for the entire system to deliver a successful outcome.

The Cooling Water System: The First Line of Defense

The cooling system is responsible for removing immense heat from the reaction chamber and microwave generator. Its failure is one of the most common causes of equipment damage.

Regular checks must confirm the proper operation of pumps, cooling towers, and water lines. Interfaces should be inspected for leaks, and regular cleaning is necessary to prevent clogs. The cooling water itself must be replenished or replaced to prevent corrosion and scale buildup, which severely degrades cooling efficiency.

The Gas Delivery System: Ensuring Process Purity

The purity and precise ratio of process gases (like methane and hydrogen) directly determine the quality of the diamond grown.

Gas pipelines must be regularly checked for tightness using a leak detector. A leak not only wastes expensive gas but, more critically, allows atmospheric contaminants like nitrogen and oxygen into the chamber, which can ruin a growth run. Flow meters must also be calibrated to ensure their accuracy.

The Vacuum System: Creating the Clean Slate

Before process gases are introduced, the reaction chamber must be pumped down to an ultra-high vacuum level to remove all contaminants.

This involves maintaining the vacuum pumps (both roughing and high-vacuum pumps) according to manufacturer specifications. All seals and o-rings on the chamber must be inspected regularly for degradation, as they are a primary source of vacuum leaks.

The Microwave System: The Heart of the Plasma

The microwave generator (magnetron) and waveguides deliver the energy that ignites and sustains the plasma.

Consistent and stable microwave power is non-negotiable for uniform material growth. While much of this system is a "black box" for operators, logs of reflected power can indicate developing problems with the chamber, tuning, or magnetron itself that require specialist attention.

Understanding the Risks and Trade-offs

Proper maintenance is an investment, but deferring it carries far greater costs and safety risks.

The True Cost of Deferred Maintenance

A minor coolant flow issue might seem insignificant, but it can lead to chamber overheating. This can cause the quartz bell jar to warp or crack, resulting in a catastrophic vacuum failure and costly repairs that halt all production for weeks.

The Hazard of Improper Procedures

Attempting to service this equipment without proper training is extremely dangerous. Risks include exposure to lethal high voltages, harmful microwave radiation, and the ignition of flammable gases like hydrogen. Always defer to professionals.

The Balance of Maintenance

While under-maintenance is risky, over-maintenance can also be a problem. Unnecessarily disassembling components can introduce new leaks or misalignments. A maintenance schedule should be based on manufacturer recommendations, logbook data, and operational experience, not arbitrary teardowns.

Implementing Your Maintenance Protocol

Your specific maintenance protocol should be tailored to your primary operational goal.

- If your primary focus is maximizing uptime and production throughput: Implement rigorous daily and weekly checklists for operators to catch and report subtle deviations before they become system failures.

- If your primary focus is ensuring the highest research-grade material quality: Prioritize meticulous vacuum leak checks, gas purity verification before every run, and a strict post-run chamber cleaning protocol to eliminate cross-contamination.

- If your primary focus is extending equipment lifespan and managing budget: Emphasize scheduled preventative maintenance on mechanical parts like pumps and chillers, and use a detailed log to track component performance and justify replacements.

A well-maintained MPCVD system is not an expense; it is the foundation of reliable and repeatable results.

Summary Table:

| Subsystem | Key Maintenance Focus | Common Risks of Neglect |

|---|---|---|

| Cooling Water | Pump operation, leak checks, water quality | Overheating, chamber damage, system failure |

| Gas Delivery | Leak tightness, flow meter calibration | Contamination, wasted gas, poor deposition quality |

| Vacuum System | Pump maintenance, seal and o-ring inspection | Vacuum leaks, process contamination |

| Microwave System | Power stability monitoring, specialist servicing | Unstable plasma, non-uniform growth |

Ensure your MPCVD equipment delivers consistent, high-quality results. A proactive maintenance strategy is essential for labs focused on advanced material synthesis like diamond growth. At KINTEK, we leverage our deep expertise in high-temperature systems and in-house manufacturing to provide robust MPCVD solutions and tailored support. Our strong customization capabilities mean we can help you design and maintain a system perfectly aligned with your research or production goals. Don't let equipment downtime compromise your work—contact our experts today to discuss your MPCVD maintenance and performance needs.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab