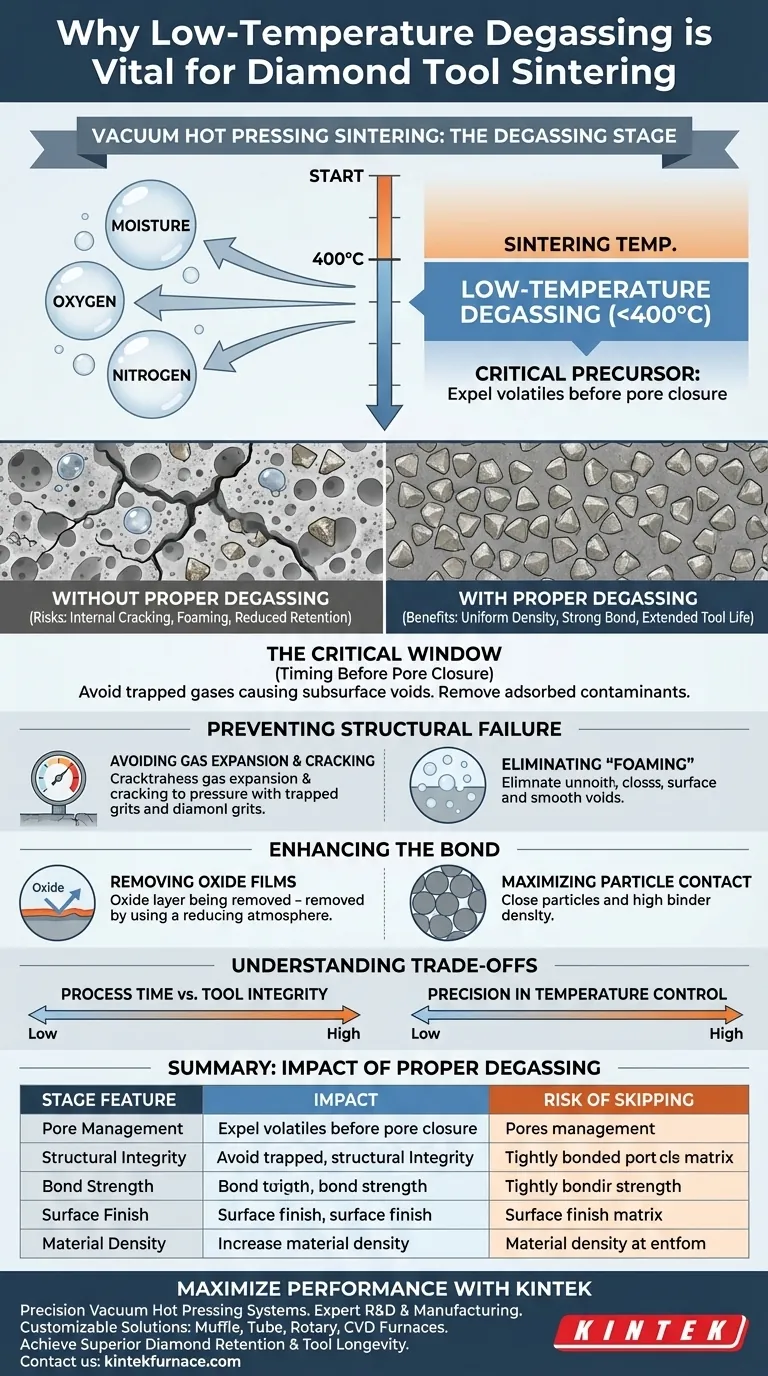

Low-temperature degassing is the critical precursor to successful sintering. In the vacuum hot pressing of diamond products, this stage—typically occurring below 400°C—is required to expel moisture, oxygen, and nitrogen from the powder surface before metal particles begin to melt or form closed pores.

The primary necessity of low-temperature degassing is to eliminate volatile substances that would otherwise become trapped within the diamond tool's matrix, causing internal cracking, product foaming, and reduced diamond retention.

The Critical Window: Why 400°C Matters

Timing Before Pore Closure

Degassing must occur early in the heating cycle because once the metal powder reaches its softening point, closed pores begin to form. If gases are not evacuated before this transition, they become permanently trapped within the structure, leading to subsurface voids.

Expelling Volatile Contaminants

Powder surfaces naturally adsorb moisture, oxygen, and nitrogen from the atmosphere. The low-temperature phase provides the thermal energy necessary to break these surface bonds and allow the vacuum system to draw the contaminants out of the mold.

Preventing Structural Failure and Porosity

Avoiding Gas Expansion and Cracking

As the sintering temperature rises toward the final set point, any trapped gas will expand rapidly according to the ideal gas law. This internal pressure can exceed the green strength of the material, resulting in micro-cracks or catastrophic structural failure.

Eliminating Product "Foaming"

"Foaming" occurs when trapped gases expand during the molten or semi-molten phase of the metal binder. By ensuring a thorough vacuum degassing phase, you prevent the formation of these bubbles, ensuring the final tool has a uniform, dense cross-section.

Enhancing the Bond: Diamond Retention and Density

Removing Oxide Films

Vacuum hot pressing systems often utilize a reducing atmosphere in conjunction with degassing to eliminate oxide films on metal particles. Removing these oxides is essential for the metal to "wet" the diamond surface effectively.

Maximizing Particle Contact

By clearing the powder surfaces of gas molecules and oxides, the system facilitates unhindered contact between metal particles. This leads to significantly higher binder density and a much stronger mechanical hold on the diamond grits.

Understanding the Trade-offs

Process Time vs. Tool Integrity

The most significant trade-off in low-temperature degassing is the cycle time. While a faster ramp-up to sintering temperatures increases throughput, it risks "locking in" volatiles; conversely, an overly long degassing phase can slow production without providing additional marginal benefits.

Precision in Temperature Control

If the degassing temperature fluctuates too high, premature surface sintering can occur. This creates a "crust" that prevents deeper gases from escaping, effectively defeating the purpose of the degassing stage and leading to inconsistent batch quality.

How to Apply This to Your Process

When configuring your vacuum hot pressing cycle, your approach to degassing should be dictated by your specific material requirements.

- If your primary focus is Maximum Tool Life: Ensure a thorough degassing dwell time near 400°C to maximize diamond retention force and binder density.

- If your primary focus is Aesthetic Surface Finish: Prioritize the removal of all moisture and nitrogen early in the cycle to prevent surface pitting and foaming.

- If your primary focus is High-Volume Throughput: Calibrate the vacuum level and heating rate to find the fastest possible ramp that still allows for complete volatile evacuation before pore closure.

A meticulous low-temperature degassing phase is the foundation of a high-performance diamond tool, transforming a porous powder mixture into a dense, high-strength industrial instrument.

Summary Table:

| Stage Feature | Impact of Proper Degassing | Risk of Skipping Degassing |

|---|---|---|

| Pore Management | Prevents closed pores before melting | Trapped gas creates internal voids |

| Structural Integrity | Eliminates 'foaming' and micro-cracks | Internal pressure leads to structural failure |

| Bond Strength | Removes oxide films for better wetting | Weak diamond retention and low density |

| Surface Finish | Prevents pitting and surface bubbles | Aesthetic defects and surface irregularities |

| Material Density | Maximum binder-to-particle contact | Porous matrix with reduced tool life |

Maximize Your Diamond Tool Performance with KINTEK

Don't let trapped volatiles compromise your material integrity. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum Hot Pressing systems alongside our Muffle, Tube, Rotary, and CVD furnaces—all customizable for your unique lab and industrial needs.

Our precision-engineered systems ensure consistent low-temperature degassing and high-density sintering to help you achieve superior diamond retention and tool longevity.

Ready to optimize your sintering cycle? Contact our technical experts today to find the perfect high-temperature solution for your application.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What safety features are incorporated in vacuum hot press furnaces? Ensure Operator and Equipment Protection

- Why is a vacuum environment required in a vacuum hot pressing sintering furnace when preparing ceramic tools containing metal binders? Achieve Purity for Superior Tool Performance

- How does a hot pressing (HP) system achieve full densification? Achieve 100% Density in Ti-5Al-4W-2Fe Alloys

- What role does SPS equipment play in half-Heusler fabrication? Mastering Density and Microstructure for Thermoelectrics

- Why is adjustable temperature important in a vacuum hot press furnace? Unlock Precision for Superior Materials Processing

- What are the mechanical property advantages of AlxCoCrFeNi HEAs via VHPS vs Arc Melting? Unlock Superior Hardness

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials