At its core, the Microwave Plasma Chemical Vapor Deposition (MPCVD) method is an advanced technique for growing high-quality thin films on a substrate. It achieves this by using microwave energy to excite gases into a plasma, which then facilitates the chemical deposition process. Its primary and most significant use is in the synthesis of high-purity, high-quality diamond films for industrial and scientific applications.

MPCVD is not just another deposition method; it represents the leading industrial standard for synthesizing diamond. Its key advantage lies in using a controlled, contamination-free microwave plasma, enabling a level of quality, purity, and scalability that other techniques cannot consistently match.

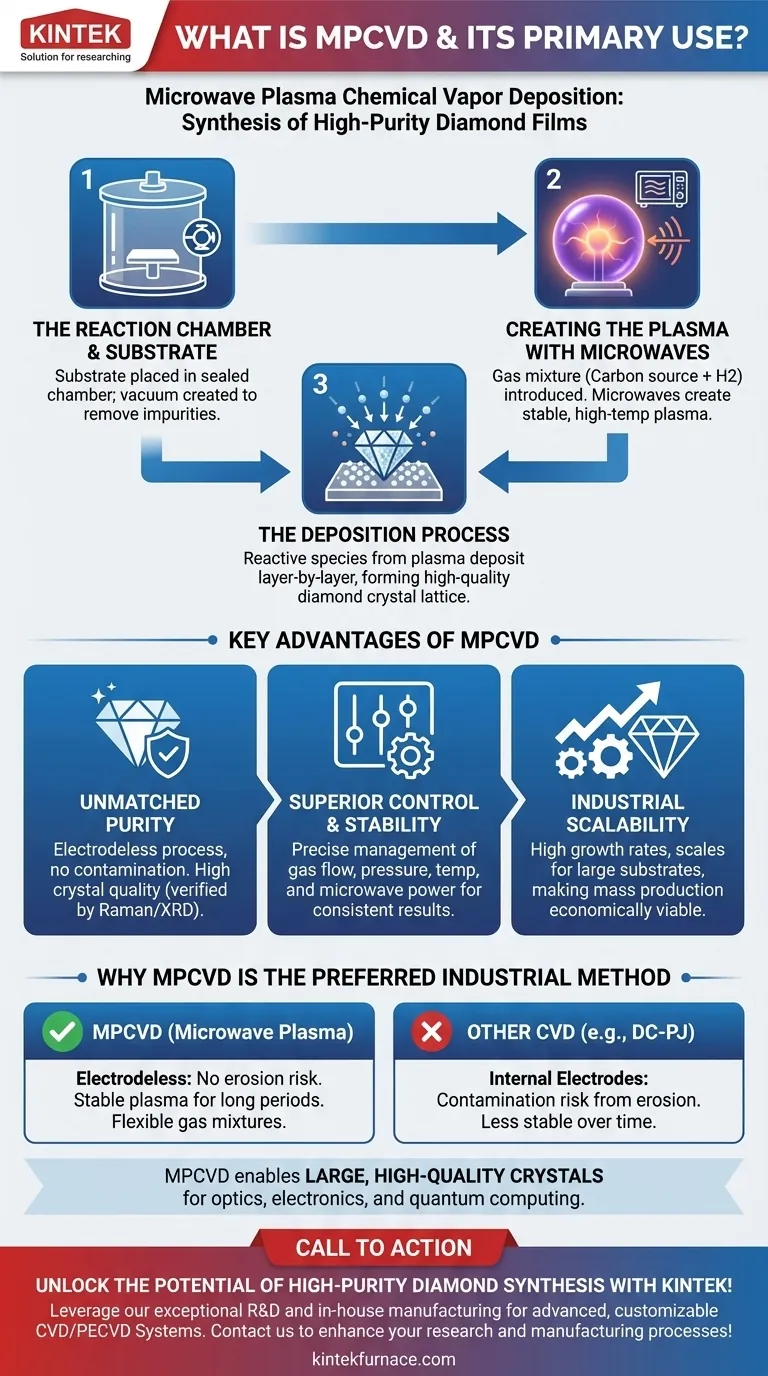

How MPCVD Works: A Step-by-Step Breakdown

The MPCVD process is precise and contained, designed to create a perfect environment for crystal growth. It unfolds in a controlled sequence within a specialized reaction chamber.

The Reaction Chamber and Substrate

First, a substrate—the material upon which the diamond will be grown—is placed on a holder inside the reaction chamber. The chamber is sealed and evacuated to a very low pressure, creating a vacuum that removes any unwanted atmospheric gases or impurities.

Creating the Plasma with Microwaves

Next, a carefully controlled mixture of gases, which includes a carbon source (like methane) and hydrogen, is introduced into the chamber. Microwaves are then directed into the chamber, energizing the gas molecules and ionizing them. This process creates a stable, high-temperature plasma—a glowing ball of charged particles.

The Deposition Process

Within this plasma, the gas molecules break down into reactive species. These species then deposit onto the surface of the substrate, arranging themselves into the crystal lattice structure of a diamond. The process continues layer by layer, building a high-quality diamond film.

The Key Advantages of MPCVD

MPCVD is considered the most promising method for industrial diamond synthesis because it solves many of the challenges faced by older techniques. Its benefits are directly responsible for its widespread adoption.

Unmatched Purity and Quality

The microwave-based process is electrodeless, meaning there are no internal components that can erode and contaminate the diamond film. This results in exceptionally high purity and excellent crystal quality, which can be verified using analytical techniques like Raman spectroscopy and X-ray diffraction (XRD).

Superior Control and Stability

MPCVD systems provide stable and highly controllable reaction conditions. Operators can precisely manage gas flow, pressure, temperature, and microwave power. This level of control ensures the consistent, repeatable production of diamond films with specific desired properties.

Industrial Scalability

The method supports high growth rates and can be scaled up to accommodate larger substrates. This scalability is critical for industrial applications, making the mass production of large, single-crystal diamonds economically viable.

Why MPCVD is the Preferred Industrial Method

While other Chemical Vapor Deposition (CVD) methods exist, such as Hot Filament (HFCVD) or Direct Current Plasma Jet (DC-PJ), MPCVD has emerged as the superior choice for high-stakes applications.

Freedom from Contamination

Unlike DC-based methods that require electrodes inside the reaction chamber, MPCVD's use of external microwaves completely eliminates the risk of electrode erosion. This is the single biggest reason for the method's ability to produce ultra-pure diamond.

Stable and Flexible Process

The plasma generated by microwaves is more stable and easier to control over long periods compared to other methods. MPCVD also allows for the flexible use of different gas mixtures, enabling fine-tuning of the diamond's characteristics.

Enabling Large, High-Quality Crystals

The combination of stability, purity, and control makes MPCVD uniquely capable of producing large, single-crystal diamonds. These are essential for advanced applications in optics, electronics, and quantum computing, where defects can derail performance.

Making the Right Choice for Your Application

Choosing a deposition method depends entirely on your end goal. MPCVD is a powerful but specialized tool, and understanding its strengths will clarify its role in your project.

- If your primary focus is producing the highest purity diamond films: MPCVD is the industry-leading choice due to its contamination-free plasma process.

- If your primary focus is industrial-scale production: The method's high growth rate, stability, and potential for large substrates make it the most viable option for manufacturing.

- If your primary focus is precise control over film properties: MPCVD offers unmatched stability and parameter control, ensuring repeatable, high-quality results for sensitive applications.

Ultimately, MPCVD provides a clear pathway to synthesizing advanced diamond materials that were once technically or economically impractical.

Summary Table:

| Aspect | Details |

|---|---|

| Method Name | Microwave Plasma Chemical Vapor Deposition (MPCVD) |

| Primary Use | Synthesis of high-purity, high-quality diamond films |

| Key Advantages | Electrodeless process, superior purity, precise control, industrial scalability |

| Ideal For | Industrial and scientific applications requiring high-quality diamond materials |

Unlock the potential of high-purity diamond synthesis for your lab! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're scaling up production or demanding precise control, our MPCVD systems deliver unmatched quality and reliability. Contact us today to discuss how we can enhance your research and manufacturing processes!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the key properties of diamond that make it a promising semiconductor material? Unlock Next-Gen Electronics

- What is a CVD machine? Build High-Performance Materials from Gas with Precision

- What is a CVD system? Achieve Atomic-Level Precision for High-Performance Coatings

- What limitations does CVD have in coating large surfaces? Overcome Scale Challenges with Custom Solutions

- How does a CVD machine work? Master the Technology for High-Quality Thin Film Deposition