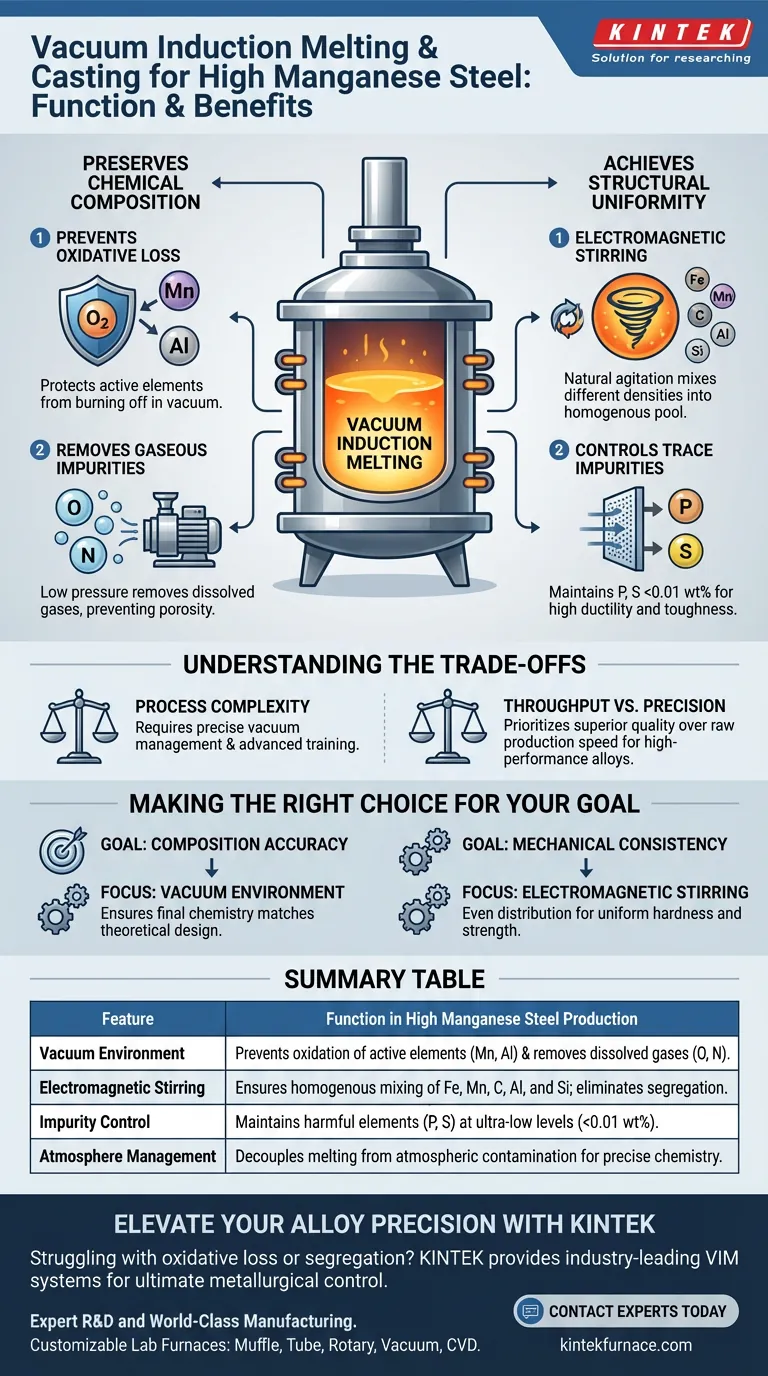

Vacuum induction melting and casting equipment functions primarily to create a controlled environment that protects reactive alloying elements while ensuring the chemical uniformity of the molten metal. By operating in a vacuum, the equipment prevents the oxidative loss of active elements like manganese and aluminum at high temperatures, while simultaneously using electromagnetic stirring to mix iron, manganese, carbon, aluminum, and silicon into a homogenous pool.

The core value of this equipment is its ability to decouple the melting process from atmospheric contamination. It safeguards the alloy's precise chemical formula by preventing oxidation and mechanically stirring the melt to ensure structural consistency throughout the ingot.

Preserving Chemical Composition

Prevention of Oxidative Loss

High manganese steel relies on specific concentrations of active elements, particularly manganese and aluminum. These elements are highly reactive and prone to "burning off" (oxidizing) when exposed to air at melting temperatures. The vacuum environment eliminates oxygen from the chamber, ensuring these critical elements remain within the alloy rather than forming slag.

Removal of Gaseous Impurities

Beyond preventing oxidation, the vacuum actively refines the molten steel. The low-pressure environment facilitates the removal of dissolved gases, such as oxygen and nitrogen, from the liquid metal. This purification is essential for preventing porosity and brittleness in the final cast product.

Achieving Structural Uniformity

The Role of Electromagnetic Stirring

A key advantage of induction technology is the generation of electromagnetic stirring forces. As the induction current heats the metal, it naturally agitates the molten pool. This ensures that elements with different densities—iron, manganese, carbon, aluminum, and silicon—are thoroughly mixed rather than settling into layers.

Controlling Trace Impurities

The precision of this equipment allows for the strict management of harmful trace elements. It creates the conditions necessary to maintain impurities like phosphorus and sulfur at extremely low levels, typically below 0.01 wt%. This low impurity baseline is critical for maximizing the ductility and toughness of the steel.

Understanding the Trade-offs

Process Complexity

While vacuum induction melting yields superior quality, it introduces significant operational complexity. Operators must precisely manage vacuum pressures and, in some cases, introduce inert atmospheres to fine-tune the melt, requiring more advanced training than standard open-air induction furnaces.

Throughput vs. Precision

This method prioritizes material quality over raw production speed. The time required to establish a vacuum and the limits on batch sizes mean this process is best reserved for high-performance alloys where chemical segregation or inclusions would cause catastrophic failure.

Making the Right Choice for Your Goal

To maximize the utility of vacuum induction melting in your production line, consider your specific metallurgical targets:

- If your primary focus is composition accuracy: Rely on the vacuum environment to prevent the evaporative loss of volatile elements like Manganese and Aluminum, ensuring the final chemistry matches your theoretical design.

- If your primary focus is mechanical consistency: Leverage the electromagnetic stirring effect to eliminate segregation, ensuring that Iron, Carbon, and Silicon are distributed evenly for uniform hardness and strength.

By effectively managing both oxidation and homogenization, this equipment transforms raw inputs into a high-purity, high-performance foundation for advanced steel manufacturing.

Summary Table:

| Feature | Function in High Manganese Steel Production |

|---|---|

| Vacuum Environment | Prevents oxidation of active elements (Mn, Al) and removes dissolved gases (O, N). |

| Electromagnetic Stirring | Ensures homogenous mixing of Fe, Mn, C, Al, and Si; eliminates segregation. |

| Impurity Control | Maintains harmful elements (P, S) at ultra-low levels (<0.01 wt%). |

| Atmosphere Management | Decouples the melting process from atmospheric contamination for precise chemistry. |

Elevate Your Alloy Precision with KINTEK

Are you struggling with oxidative loss or chemical segregation in your high-performance alloys? KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems designed to deliver the ultimate control over your metallurgical outcomes.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique preparation requirements. Whether you are refining high manganese steel or developing next-generation materials, our equipment ensures the chemical purity and structural uniformity your research demands.

Ready to optimize your melting process? Contact our technical experts today to find the perfect customized solution for your laboratory or production line.

Visual Guide

References

- Lu, Shao-Lun, Max-Planck-Institut für Nachhaltige Materialien. Making High Mn Steel by Sustainable Ferromanganese Pre-alloy for Cryogenic Applications. DOI: 10.5281/zenodo.17520990

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What maintenance benefits does the IGBT induction melting furnace offer? Achieve Unmatched Uptime and Reliability

- How does AI contribute to the efficiency of IGBT induction melting furnaces? Achieve Intelligent, Self-Optimizing Melting

- Why is a Vacuum Induction Melting (VIM) furnace necessary for H13 tool steel? Ensure Pure, High-Performance Results

- Why are induction furnaces considered optimal for aluminum melting? Achieve High Efficiency and Purity

- What are the advantages of vacuum induction melting compared to other methods? Achieve High-Purity Metals for Critical Applications

- What is an induction gold melting furnace and how does it work? Achieve Purity, Speed, and Efficiency

- What role does a Vacuum Induction Melting (VIM) furnace play in the recycling of low alloy steel? Ensure Purity.

- What are the raw materials for induction furnace? The Essential Guide to Charge & Construction Materials