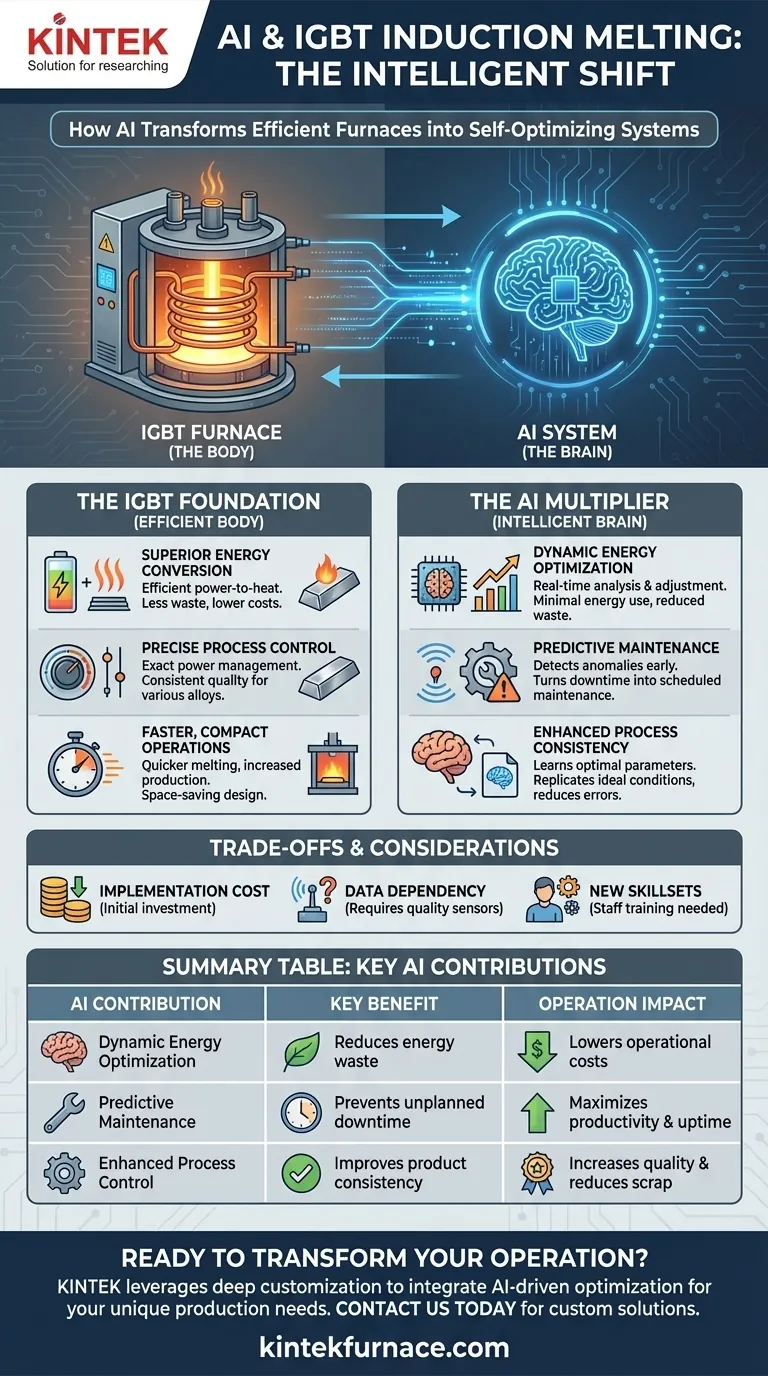

In essence, AI serves as an intelligent brain for the already efficient body of an IGBT induction melting furnace. While the IGBT hardware provides the muscle for fast, energy-efficient melting, AI introduces a layer of data-driven analysis that optimizes energy consumption, predicts mechanical failures, and automates process control to a degree that is impossible to achieve manually.

The core shift is from a highly efficient tool to an intelligent, self-optimizing system. IGBT technology provides the power and control, but AI uses real-time data to ensure that power and control are used in the most productive, cost-effective, and reliable way possible.

The Foundation: Why IGBT Furnaces Are Already Efficient

Before understanding AI's contribution, it's crucial to recognize the efficiency of the underlying technology. IGBT (Insulated-Gate Bipolar Transistor) furnaces replaced older systems by offering significant inherent advantages.

Superior Energy Conversion

IGBT technology provides a much more efficient conversion of electrical power into the heat required for melting. This means less energy is wasted during operation, leading to immediate cost savings and a smaller environmental footprint compared to legacy systems.

Precise Process Control

These furnaces allow for exact and rapid control over power levels. This precision enables operators to manage the melting process for different ferrous and non-ferrous metals and alloys, improving the quality and consistency of the final product.

Faster, More Compact Operations

The efficiency of IGBTs leads to faster melting times, which directly increases production rates. Furthermore, the technology allows for more compact furnace designs, making them suitable for smaller facilities and reducing large-scale infrastructure requirements.

The AI Multiplier: From Efficiency to Intelligence

AI takes the inherent efficiency of an IGBT furnace and multiplies its effectiveness. It does this by analyzing streams of data to make predictions and adjustments in real time.

Dynamic Energy Optimization

Instead of relying on fixed settings, an AI system constantly analyzes data like melt temperature, power draw, and cycle time. It learns the optimal energy curve for each specific alloy and batch size, adjusting power dynamically to use the absolute minimum energy required, reducing waste even further.

Predictive Maintenance and Failure Prevention

This is one of AI's most significant contributions. By monitoring vibrational data, temperature fluctuations, and electrical signatures, the AI can detect subtle anomalies that signal an impending component failure. It turns unscheduled, catastrophic downtime into scheduled, low-impact maintenance, dramatically improving overall productivity.

Enhanced Process Consistency

An AI can learn from thousands of previous melt cycles to identify the exact parameters that lead to the highest quality output. It then works to replicate those ideal conditions on every run, reducing the process variations and human error that can lead to inconsistent alloy production or failed batches.

Understanding the Trade-offs

Integrating AI is a powerful upgrade, but it is not without its challenges. Objectivity requires acknowledging the practical considerations.

The Cost of Implementation

Implementing an AI system requires an initial investment. This includes not only the software but also the installation of high-quality sensors, system integration, and potential hardware upgrades needed to collect the necessary data.

Data Dependency and Quality

An AI is only as good as the data it receives. If sensors are poorly calibrated, improperly placed, or produce unreliable data, the AI's conclusions and optimizations will be flawed. A commitment to data integrity is non-negotiable.

The Need for New Skillsets

Your team's role shifts from simply operating a furnace to overseeing an intelligent system. Staff will require training to understand the AI's recommendations, interpret its data, and manage a more technologically advanced workflow.

Making the Right Choice for Your Operation

The decision to integrate AI should be driven by your specific production goals.

- If your primary focus is reducing operational costs: AI's dynamic energy optimization and its ability to prevent costly, unplanned downtime will deliver the most direct financial return.

- If your primary focus is maximizing throughput and uptime: The predictive maintenance capabilities are the key benefit, ensuring the furnace remains operational and productive for as long as possible.

- If your primary focus is improving product quality and consistency: AI-driven process control ensures that every melt adheres to the optimal, data-proven parameters, minimizing variations and scrap.

By integrating AI, you are transforming your melting furnace from a powerful tool into a proactive, data-driven asset for your entire production line.

Summary Table:

| AI Contribution | Key Benefit | Impact on Operation |

|---|---|---|

| Dynamic Energy Optimization | Reduces energy waste | Lowers operational costs |

| Predictive Maintenance | Prevents unplanned downtime | Maximizes productivity and uptime |

| Enhanced Process Control | Improves product consistency | Increases quality and reduces scrap |

Ready to transform your melting operation into an intelligent, self-optimizing system?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Our high-temperature furnaces, including Induction Melting Systems, are designed for peak performance. Our strong deep customization capability allows us to integrate intelligent features like AI-driven optimization to precisely meet your unique production requirements for ferrous and non-ferrous metals.

Contact us today to discuss how an AI-enhanced furnace can maximize your efficiency, uptime, and product quality.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are multiple repeated melting cycles necessary in the production of Ni-Ti-Hf-La alloys? Ensuring Homogenization

- What role does a vacuum induction furnace play in Fe-Mn-Si alloy melting? Ensuring Purity and Shape Memory Precision

- What is the function of a VIM furnace for DP steel? Master High-Purity Casting and Chemical Precision

- What role does the coil play in the IGBT melting process? It's the Key to Efficient Induction Heating

- What is a vacuum casting furnace and what is its primary purpose? Achieve Purity in High-Performance Metal Casting

- What are the technical advantages of using an induction furnace for lithium battery recycling over resistance heating?

- Why is a Vacuum Induction Melting (VIM) furnace preferred for AlCoCrFeNi High-Entropy Alloys? Achieve Peak Purity.

- How do vacuum melting furnaces contribute to the preparation of high-purity medium-manganese steel ingots?