The primary advantage of vacuum induction melting (VIM) is its unparalleled ability to produce exceptionally high-purity and chemically precise metals and alloys. By combining the efficiency of induction heating with a controlled vacuum environment, this process eliminates atmospheric contamination and provides metallurgists with precise control over the final product. The result is a material with superior integrity, ideal for the most demanding applications.

When developing advanced materials for critical industries like aerospace or medicine, even trace impurities can lead to catastrophic failure. Vacuum induction melting directly solves this by creating a sterile melting environment, giving engineers ultimate control over the alloy's final integrity and composition.

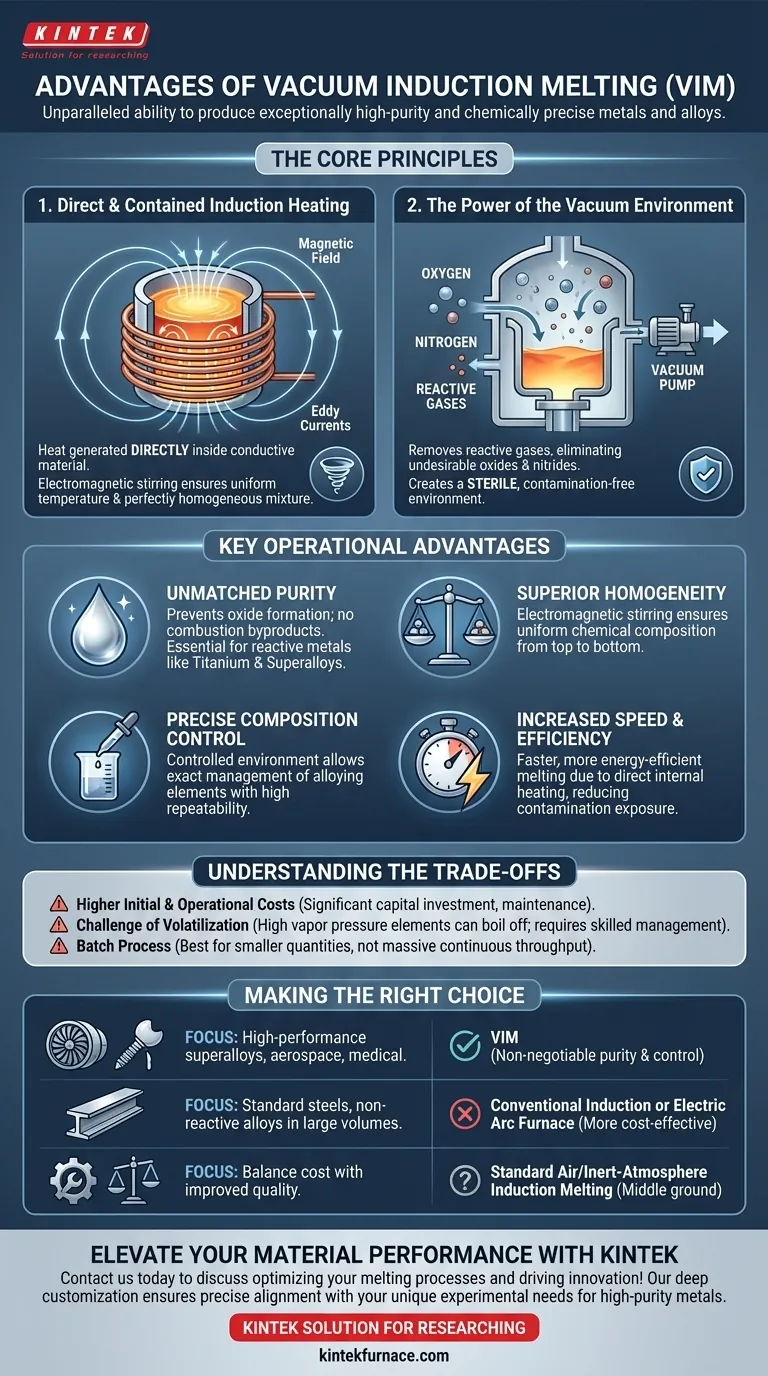

The Core Principles: How VIM Achieves Superior Quality

To understand the advantages of VIM, it's essential to understand its two core technologies: induction heating and the vacuum environment. They work together to create a sum greater than their parts.

Direct and Contained Heating

Unlike fuel-fired or arc furnaces that heat material from the outside using convection and radiation, induction heating generates heat directly inside the conductive material itself. An alternating current in a copper coil creates a powerful magnetic field, which induces eddy currents within the metal charge, causing it to heat and melt rapidly from within.

This internal heating mechanism also creates a natural, electromagnetic stirring action in the molten bath. This ensures a uniform temperature and a perfectly homogeneous mixture of alloying elements, preventing segregation and inconsistencies in the final product.

The Power of the Vacuum

The "vacuum" component is what truly distinguishes VIM. By pumping the air out of the melting chamber, we remove reactive gases like oxygen and nitrogen.

This is critical because these gases readily react with molten metals to form undesirable oxides and nitrides. These impurities can compromise a material's mechanical properties, such as its strength, ductility, and fatigue resistance. The vacuum effectively creates a sterile, contamination-free environment for melting.

Key Operational Advantages

The combination of these principles delivers a clear set of operational benefits that are difficult to achieve with other methods.

Unmatched Purity and Cleanliness

The primary benefit is the production of extremely clean metals. The vacuum prevents the formation of oxides, and the absence of combustion byproducts (as seen in gas furnaces) means no contaminants are introduced during the melt. This is essential for reactive metals like titanium and nickel-based superalloys.

Superior Homogeneity and Compositional Control

The electromagnetic stirring inherent to induction ensures all alloying elements are distributed evenly, leading to a chemically uniform product from top to bottom. Furthermore, the controlled vacuum or partial-pressure inert gas atmosphere allows for precise management of the final chemical composition, hitting tight specifications with high repeatability.

Increased Speed and Energy Efficiency

Because heat is generated directly within the material, melting is significantly faster and more energy-efficient than traditional methods that must first heat the furnace walls and atmosphere. This rapid melting also reduces the time the molten metal is exposed to potential (though minimal) contamination sources.

Understanding the Trade-offs

No technology is without its compromises. Acknowledging the limitations of VIM is crucial for making an informed decision.

Higher Initial and Operational Costs

Vacuum induction furnaces are complex systems. The vacuum chamber, high-capacity pumps, and sophisticated control systems represent a significant capital investment compared to standard atmosphere furnaces. Maintenance of these vacuum systems also adds to the operational cost.

The Challenge of Volatilization

Under a hard vacuum, some elements with high vapor pressure (such as manganese, lead, or zinc) can "boil off" or vaporize from the molten bath. This can unintentionally alter the final alloy composition. Skilled operators manage this by carefully controlling the vacuum level and temperature, often using a partial pressure of an inert gas like argon to suppress the effect.

Batch Size and Throughput

VIM is fundamentally a batch process best suited for producing high-value materials in smaller quantities (from a few kilograms to several tons). It is not designed for the massive-scale, continuous throughput seen in commodity steel production, where methods like the electric arc furnace are more economical.

Making the Right Choice for Your Application

Choosing your melting technology depends entirely on your material requirements and economic constraints.

- If your primary focus is producing high-performance superalloys, medical implants, or aerospace components: VIM is often the only viable choice due to its non-negotiable purity and compositional control.

- If your primary focus is melting standard steels or non-reactive alloys in large volumes: A conventional induction furnace or electric arc furnace will be far more cost-effective.

- If your primary focus is balancing cost with improved quality over traditional methods: Standard air or inert-atmosphere induction melting may offer a suitable middle ground without the full expense of a vacuum system.

Ultimately, selecting vacuum induction melting is a strategic decision to prioritize material integrity and performance above all other factors.

Summary Table:

| Advantage | Description |

|---|---|

| High Purity | Eliminates atmospheric contamination for exceptionally clean metals and alloys. |

| Superior Homogeneity | Ensures uniform chemical composition with electromagnetic stirring. |

| Precise Control | Allows exact management of alloy composition in a vacuum environment. |

| Energy Efficiency | Faster melting with direct internal heating reduces energy use and exposure time. |

Elevate your material performance with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vacuum induction melting systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for high-purity metals in aerospace, medical, and other critical applications. Contact us today to discuss how we can optimize your melting processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the technical advantages of using a vacuum stir casting system? Engineered Magnesium Alloy Precision

- Why is vacuum environment important in VIM furnaces? Achieve High-Purity Alloys with Precision Control

- What are the advantages of using medium-frequency induction heating for Ir/HfO2? Boost Coating Purity & Efficiency

- How does induction heating contribute to a cleaner work environment? Boost Quality & Sustainability

- What is the role of the vacuum system in a vacuum casting furnace? Ensure Purity and Performance in Metal Casting

- What is the role of a medium-frequency vacuum induction furnace? Enhance Purity in High-Strength Spring Steel

- What is the working process of an induction furnace? Discover Contactless, High-Efficiency Metal Melting

- What is the role of frequency in melting PGM powders in an induction furnace? Essential for efficient heating and melting.