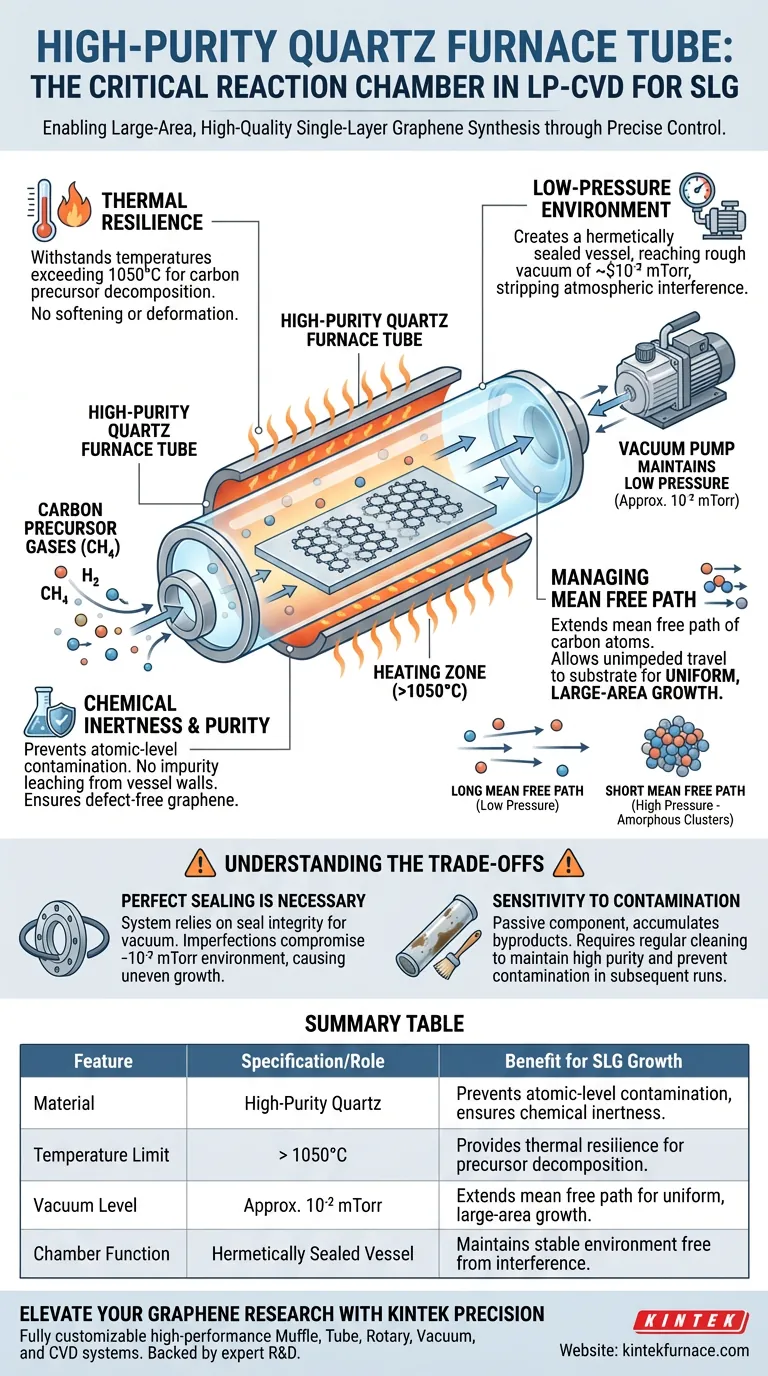

The high-purity quartz furnace tube acts as the critical reaction chamber in Low-Pressure Chemical Vapor Deposition (LP-CVD) systems, specifically engineered to withstand the rigorous conditions required for Single-Layer Graphene (SLG) synthesis. It serves as a hermetically sealed vessel that sustains temperatures exceeding 1050°C while maintaining a chemically inert environment. By integrating seamlessly with vacuum pump sets, it holds the system at a vacuum level of approximately $10^{-2}$ mTorr. This precise control over temperature and pressure is the deciding factor in achieving large-area, high-quality graphene growth.

The quartz tube is not merely a container; it is an active enabler of purity and gas dynamics. Its ability to maintain high vacuum at extreme heat allows for the manipulation of the carbon source's mean free path, ensuring the graphene grows uniformly rather than forming amorphous clusters.

The Critical Role of Material Properties

Thermal Resilience at Extreme Temperatures

The synthesis of Single-Layer Graphene requires high energy to break down carbon precursor gases and rearrange them into a hexagonal lattice. The quartz tube provides the necessary thermal stability to operate safely at temperatures exceeding 1050°C. Standard glass or lower-grade ceramics would soften, deform, or outgas under these conditions.

Chemical Inertness and Purity

The "high-purity" designation of the quartz is functional, not just descriptive. At the atomic level, graphene is incredibly sensitive to contamination. The quartz tube offers excellent chemical stability, ensuring that no impurities from the vessel walls leach into the reaction zone to create defects in the graphene sheet.

Enabling the Physics of Growth

Creating the Low-Pressure Environment

To grow a single, uniform layer of atoms, the density of gas molecules must be strictly controlled. The quartz tube's superior sealing performance is vital when paired with vacuum pump sets. It allows the system to reach and maintain a rough vacuum of approximately $10^{-2}$ mTorr, stripping away atmospheric interference.

Managing the Mean Free Path

The vacuum environment created by the tube directly influences the "mean free path"—the average distance a gas molecule travels before colliding with another. By maintaining low pressure, the quartz tube extends this mean free path. This allows carbon atoms to travel unimpeded to the substrate, facilitating the large-area, uniform growth characteristic of high-quality SLG.

Understanding the Trade-offs

The Necessity of Perfect Sealing

While the tube itself is robust, the system is only as effective as its integration with the vacuum pumps. Relying on the tube for vacuum integrity means that any imperfection in the seals or flanges will compromise the $10^{-2}$ mTorr environment. A loss of pressure control immediately reduces the mean free path, leading to uneven or multi-layer growth.

Sensitivity to Contamination Accumulation

Although the quartz is chemically stable, it is a passive component that cannot actively clean itself during a run. Over time, reaction byproducts can accumulate on the inner walls. Because the process relies on such high purity, even minor residual buildup on the quartz surface can alter the thermal profile or introduce contaminants in subsequent runs.

Making the Right Choice for Your Goal

To maximize the effectiveness of your LP-CVD system for graphene preparation, you must align your equipment maintenance with your specific output goals.

- If your primary focus is Atomic Purity: Prioritize the regular cleaning and inspection of the quartz tube's inner surface to ensure the chemical stability prevents any impurity contamination at 1050°C.

- If your primary focus is Large-Area Uniformity: Focus heavily on the tube's sealing interfaces and vacuum pump performance to rigorously maintain the $10^{-2}$ mTorr pressure required to control the mean free path.

The quartz furnace tube is the foundational hardware that translates theoretical growth parameters into physical, high-quality Single-Layer Graphene.

Summary Table:

| Feature | Specification/Role | Benefit for SLG Growth |

|---|---|---|

| Material | High-Purity Quartz | Prevents atomic-level contamination and ensures chemical inertness. |

| Temperature Limit | > 1050°C | Provides thermal resilience for carbon precursor decomposition. |

| Vacuum Level | Approx. $10^{-2}$ mTorr | Extends the mean free path for uniform, large-area growth. |

| Chamber Function | Hermetically Sealed Vessel | Maintains a stable environment free from atmospheric interference. |

Elevate Your Graphene Research with KINTEK Precision

Achieving perfect Single-Layer Graphene requires equipment that never compromises on purity or pressure control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific laboratory requirements.

Whether you are scaling up SLG production or perfecting atomic purity, our high-purity quartz solutions and advanced furnace systems provide the thermal stability and vacuum integrity your research demands.

Ready to optimize your LP-CVD process? Contact our technical experts today to find the ideal high-temperature furnace for your unique needs.

Visual Guide

References

- Songsong Yao, Tongxiang Fan. Effect of Copper Surface Roughness on the High-Temperature Structural Stability of Single-Layer-Graphene. DOI: 10.3390/ma17071648

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the environmental concerns related to CVD? Managing Risks in Thin Film Coating

- Why is a high-vacuum thermal evaporation system required for gold back electrodes? Ensure Pure, High-Efficiency Contacts

- What are the roles of the vacuum pumping system and argon gas input in TiN/Cr deposition? Ensure Peak Coating Purity

- What industries commonly use PVD and CVD? Discover Key Applications in Tech and Manufacturing

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- How does a CVD reactor work? Master Thin-Film Deposition for Advanced Materials

- How does Chemical Vapor Deposition (CVD) differ from Physical Vapor Deposition (PVD)? Choose the Right Thin-Film Process