In the context of hot-dip galvanizing dross treatment, the industrial-grade muffle furnace acts as the foundational vessel for thermal conditioning and material standardization. During the initial processing stages, it provides a stable, high-temperature environment required to melt raw dross materials. When paired with mechanical agitation, this allows for the complete homogenization of zinc, aluminum, and iron components.

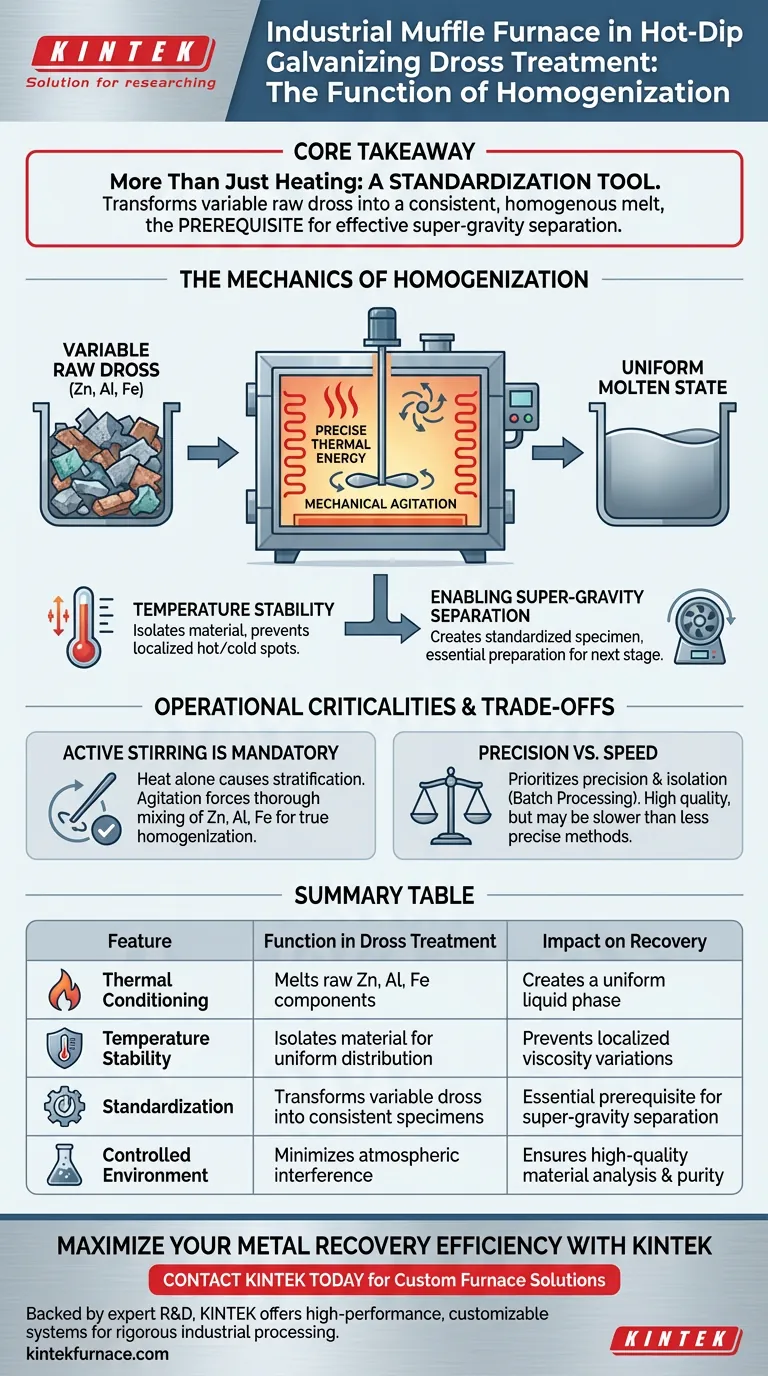

Core Takeaway The muffle furnace is not just a heating element; it is a standardization tool. Its primary function is to transform variable raw dross into a consistent, homogenous melt, which is the absolute prerequisite for effective downstream super-gravity separation.

The Mechanics of Homogenization

Creating a Uniform Molten State

The primary objective of using a muffle furnace in this application is consistency. Raw galvanizing dross is often chemically heterogeneous.

The furnace generates the precise thermal energy needed to bring the distinct components—zinc, aluminum, and iron—into a fully molten phase. This eliminates solid-state variations that would otherwise disrupt processing.

The Role of Temperature Stability

Unlike open-flame heating, a muffle furnace isolates the material to ensure uniform temperature distribution.

This stability prevents localized hot or cold spots within the dross. Uniform heating is critical to ensure that all metallic phases reach the same viscosity and state of fusion simultaneously.

Enabling Super-Gravity Separation

The output of the muffle furnace is a standardized specimen. This step is not the final treatment but the essential preparation for the next stage.

By ensuring the dross has a consistent composition, the furnace prepares the material for super-gravity separation. Without this prior homogenization, gravity-based separation techniques would yield unpredictable and inefficient results.

Operational Criticalities and Trade-offs

The Requirement for Active Stirring

It is important to note that thermal energy alone is insufficient for true homogenization.

The muffle furnace must be coupled with appropriate stirring mechanisms. While the furnace maintains the melt, the physical agitation forces the distinct elements (Zn, Al, Fe) to mix thoroughly. Relying on the furnace without stirring will result in stratification rather than homogenization.

Energy Intensity vs. Precision

Industrial muffle furnaces prioritize precision and isolation over rapid throughput.

This equipment is designed for batch-style processing where control over the atmosphere and temperature curve is paramount. This ensures high-quality results but may represent a bottleneck in high-volume, continuous-flow production lines compared to less precise heating methods.

Making the Right Choice for Your Process

## Optimizing Dross Recovery Workflows

To maximize the utility of an industrial muffle furnace in your galvanizing recovery line, consider your specific end-goals:

- If your primary focus is Separation Efficiency: Prioritize temperature stability to ensure the melt viscosity is perfectly uniform before entering the super-gravity separator.

- If your primary focus is Material Analysis: Ensure your stirring protocols are rigorous, as the furnace provides the heat, but the agitation guarantees the representative composition needed for accurate sampling.

The muffle furnace is the gatekeeper of quality in dross recycling; it ensures that the chaotic raw material is tamed into a predictable state for valuable metal recovery.

Summary Table:

| Feature | Function in Dross Treatment | Impact on Recovery |

|---|---|---|

| Thermal Conditioning | Melts raw Zn, Al, and Fe components | Creates a uniform liquid phase |

| Temperature Stability | Isolates material for uniform distribution | Prevents localized viscosity variations |

| Standardization | Transforms variable dross into consistent specimens | Essential prerequisite for super-gravity separation |

| Controlled Environment | Minimizes atmospheric interference | Ensures high-quality material analysis and purity |

Maximize Your Metal Recovery Efficiency with KINTEK

Precise homogenization is the foundation of profitable dross recycling. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of industrial material processing.

Whether you are refining hot-dip galvanizing dross or performing complex material analysis, our precision-engineered high-temperature furnaces provide the thermal stability you need for superior results. Contact KINTEK today to discuss your custom furnace solution and see how our expertise can optimize your laboratory or production workflow.

Visual Guide

References

- S. J. Zhang, Zhancheng Guo. Purification and Recovery of Hot-Dip Galvanizing Slag via Supergravity-Induced Cake-Mode Filtration. DOI: 10.3390/met14010100

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a muffle furnace reduce contamination during heating? Ensure Purity in Your Lab Processes

- What is a box furnace and what are its main characteristics? Discover Versatile Batch Heating Solutions

- How does a high-temperature muffle furnace facilitate the conversion of precursors? Unlock Peak Catalytic Performance

- How do laboratory high-temperature furnaces assist in determining the annealing temperatures? Replicate Ancient Metalwork

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What is the function of a muffle furnace during catalyst calcination? Master Biomass-to-Catalyst Transformation

- How does a precision temperature-controlled box furnace optimize Cu-Cr-Zr-La alloys? Enhance Material Performance

- What is the specific application of a high-temperature box resistance furnace for TiBw/TA15? Master Thermal Prepping