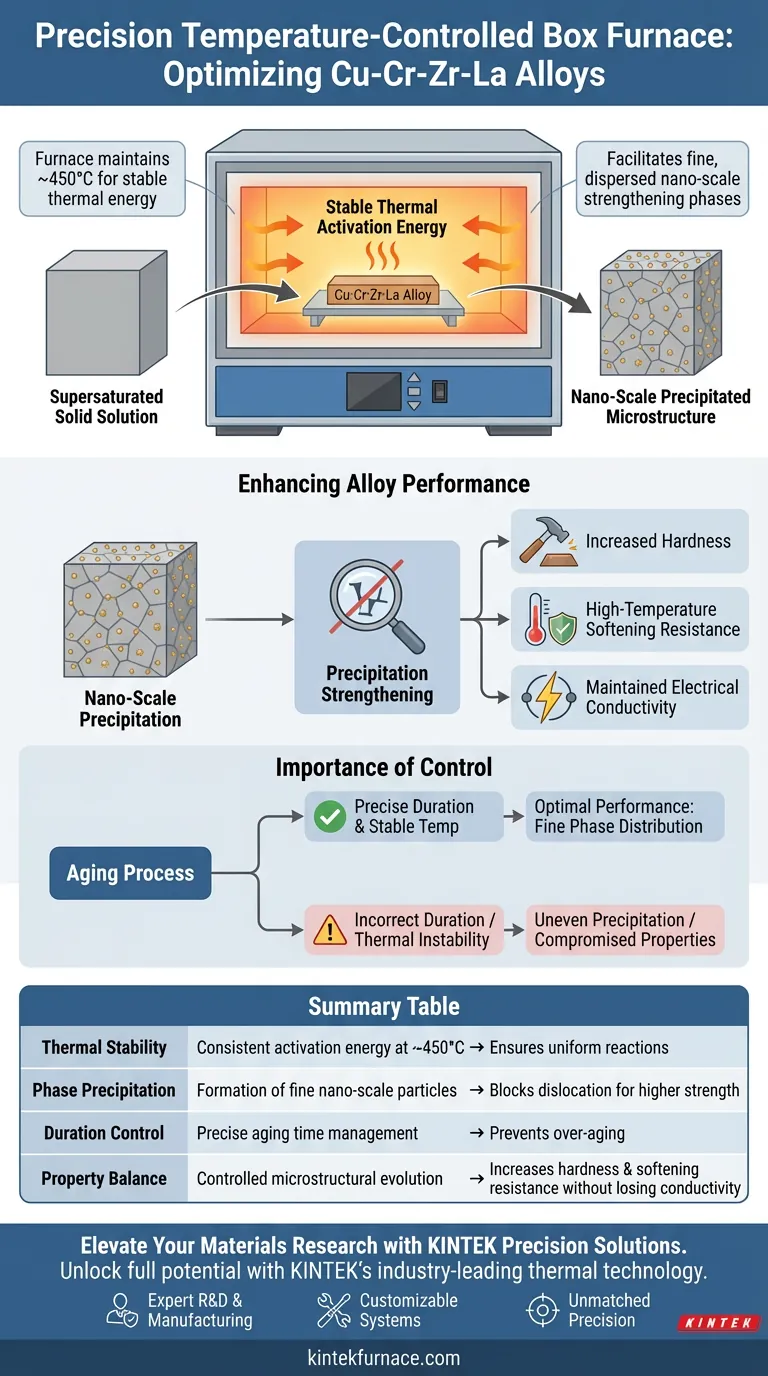

A precision temperature-controlled box furnace optimizes Cu-Cr-Zr-La alloys by delivering stable thermal activation energy. By maintaining exact temperatures, typically around 450°C, the furnace facilitates the precipitation of fine, dispersed nano-scale phases from the alloy's supersaturated solid solution. This precise thermal management is essential for enhancing mechanical properties while preserving electrical performance.

Precision aging allows for maximum precipitation strengthening, which significantly boosts the alloy's hardness and resistance to softening at high temperatures without degrading its electrical conductivity.

The Role of Thermal Precision in Microstructural Evolution

To understand how the furnace optimizes the alloy, we must look at the microscopic changes driven by precise heat application.

Providing Stable Activation Energy

The core function of the furnace is to supply stable thermal activation energy. This energy is the catalyst required to initiate changes within the alloy's internal structure. Without a stable heat source, the necessary chemical and physical reactions cannot occur uniformly.

Promoting Nano-Scale Precipitation

The furnace promotes the formation of fine, dispersed nano-scale strengthening phases. These phases emerge from the supersaturated solid solution during the aging process. The precision of the furnace ensures these particles remain small and well-distributed, which is critical for strengthening the material.

Enhancing Alloy Performance

The microstructural changes facilitated by the furnace directly translate into improved macroscopic properties.

Maximizing Precipitation Strengthening

By precisely controlling the temperature and duration of the aging process, the furnace maximizes precipitation strengthening. This mechanism blocks dislocation movement within the metal, making it physically stronger.

Increasing Hardness and Softening Resistance

The direct result of this strengthening is a significant increase in the hardness of the Cu-Cr-Zr-La alloy. Additionally, the process improves high-temperature softening resistance, ensuring the material retains its strength even when exposed to heat during service.

Maintaining Electrical Conductivity

Crucially, this process optimizes mechanical strength while maintaining high electrical conductivity. Often, strengthening mechanisms reduce conductivity, but the precise precipitation of nano-scale phases allows for a superior balance of both properties.

Understanding the Necessity of Control

While the furnace enables optimization, the parameters must be exact to achieve the desired results.

The Importance of Duration Control

The reference highlights the need for precisely controlling the aging duration. If the duration is incorrect, the "fine" nature of the dispersed phases could be compromised.

The Risk of Thermal Instability

If the furnace fails to provide stable energy at the specific temperature (e.g., 450°C), the activation energy will be inconsistent. This would lead to uneven precipitation, resulting in an alloy with unpredictable mechanical and electrical characteristics.

Making the Right Choice for Your Goal

To fully leverage a precision box furnace for Cu-Cr-Zr-La alloys, align your process parameters with your specific performance needs.

- If your primary focus is Maximum Hardness: Ensure the furnace maintains a stable 450°C to drive the full precipitation of nano-scale strengthening phases.

- If your primary focus is High-Temperature Stability: Prioritize precise duration control to maximize softening resistance without over-aging the material.

By strictly controlling thermal activation energy, you transform the alloy into a high-performance material that resists heat and deformation while conducting electricity efficiently.

Summary Table:

| Optimization Factor | Mechanism & Benefit | Impact on Cu-Cr-Zr-La Alloy |

|---|---|---|

| Thermal Stability | Consistent activation energy at ~450°C | Ensures uniform chemical & physical reactions |

| Phase Precipitation | Formation of fine nano-scale particles | Blocks dislocation movement for higher strength |

| Duration Control | Precise aging time management | Prevents over-aging; maintains fine phase distribution |

| Property Balance | Controlled microstructural evolution | Increases hardness & softening resistance without losing conductivity |

Elevate Your Materials Research with KINTEK Precision Solutions

Unlock the full potential of your high-performance alloys with KINTEK’s industry-leading thermal technology. Whether you are optimizing Cu-Cr-Zr-La alloys or developing next-generation materials, our precision temperature-controlled box furnaces provide the stable thermal environment necessary for uniform nano-scale precipitation and superior mechanical properties.

Why choose KINTEK?

- Expert R&D & Manufacturing: Specialized equipment designed for rigorous laboratory standards.

- Customizable Systems: From Muffle and Tube furnaces to Rotary, Vacuum, and CVD systems, we tailor solutions to your unique heat treatment requirements.

- Unmatched Precision: Maintain exact temperatures to ensure consistent hardness and electrical conductivity in every batch.

Ready to enhance your lab's efficiency and material quality? Contact us today to discuss your project needs!

Visual Guide

References

- Hairui Zhi, Haitao Zhao. Low cycle fatigue behavior of Cu-Cr-Zr-La alloys. DOI: 10.1088/1742-6596/2951/1/012133

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What controls the temperature regulation in a muffle furnace? Master Precision with Advanced PID Controllers

- What are the common applications of a muffle furnace in metallurgy? Enhance Metal Properties with Precision Heat Treatment

- What is a muffle furnace used for? Achieve Pure, High-Temperature Processing

- What should be avoided when operating a muffle furnace? Key Safety Tips to Prevent Damage and Hazards

- How does a muffle furnace facilitate the dehydroxylation of kaolin? Master Thermal Conversion to Metakaolin

- What is the role of muffle furnaces in the pretreatment of medical samples? Essential for Accurate Trace Element Analysis

- What is a muffle furnace and its primary use? Discover High-Temp, Contamination-Free Heating Solutions

- How should heated crucibles be handled after removal from the furnace? Ensure Accurate Results with Proper Cooling