In medical laboratories, a muffle furnace performs the critical function of sample reduction through a process called ashing. This high-temperature procedure is designed to burn away all organic material—such as tissue, blood, or other biological matrices—leaving behind only the inorganic, non-combustible components for subsequent analysis.

The fundamental role of a muffle furnace is to thermally purify a medical sample. It removes the complex organic "noise" so that modern analytical instruments can clearly and accurately measure the inorganic "signal" of trace elements and minerals.

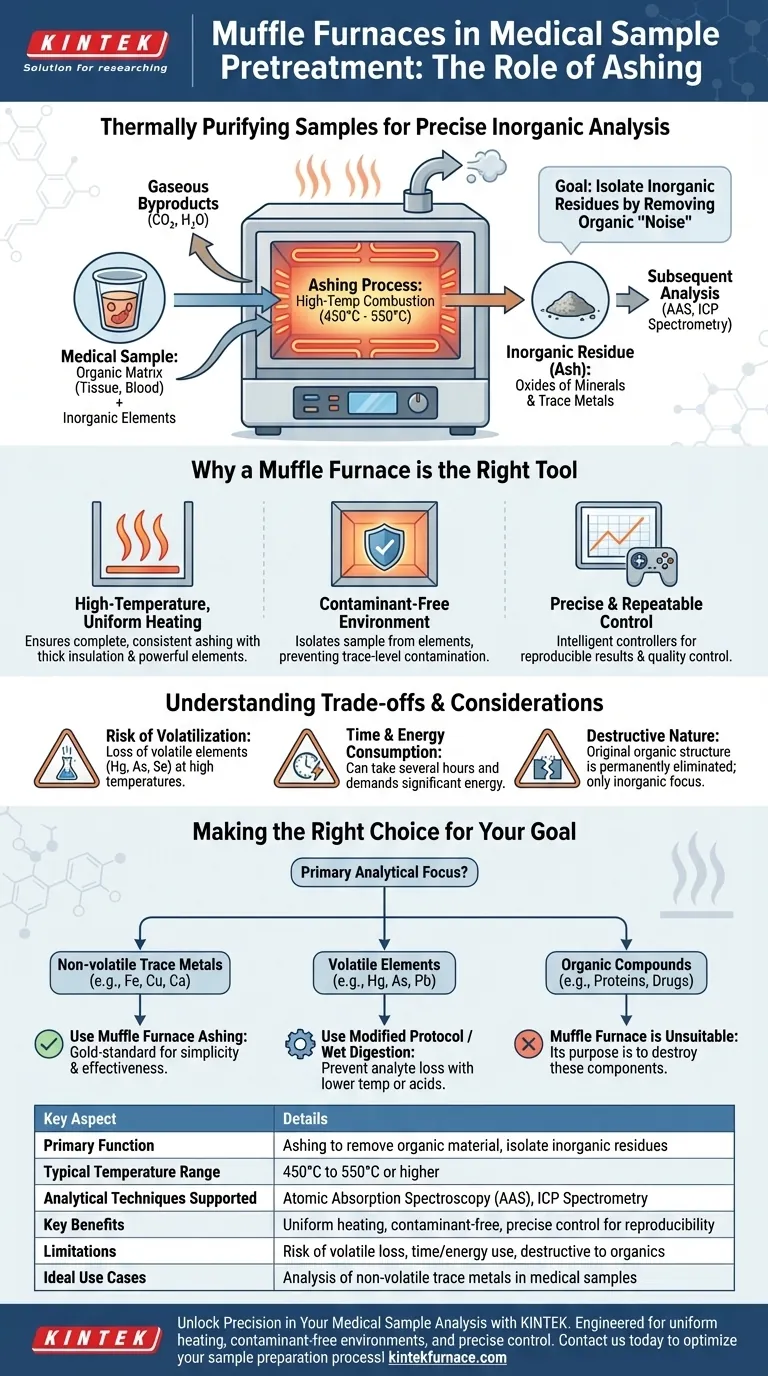

The Core Function: Ashing for Inorganic Analysis

The primary use of a muffle furnace in this context is to prepare a sample for techniques that measure elemental composition, such as atomic absorption spectroscopy (AAS) or inductively coupled plasma (ICP) spectrometry.

What is Ashing?

Ashing is a process of high-temperature combustion in a controlled environment. The medical sample is placed in a crucible and heated in the furnace to temperatures typically ranging from 450°C to 550°C, or higher.

At these temperatures, all organic compounds (carbon-based molecules like proteins, fats, and carbohydrates) react with oxygen and are converted into gaseous byproducts like carbon dioxide and water, which vent away.

The Goal: Isolating Inorganic Residues

What remains after complete combustion is a small amount of ash. This ash contains the sample's full complement of inorganic elements, such as essential minerals (calcium, potassium) and trace metals (iron, copper, zinc), in the form of oxides.

Why This is Essential for Analysis

Analytical instruments like spectrometers are extremely sensitive, but their accuracy can be compromised by the presence of a large, complex organic matrix.

Burning away the organic material concentrates the inorganic elements of interest and eliminates potential interference, allowing for a much more accurate and reliable quantitative measurement.

Why a Muffle Furnace is the Right Tool

While other heating methods exist, the specific design of a muffle furnace makes it uniquely suited for the demands of precise scientific analysis.

High-Temperature, Uniform Heating

Muffle furnaces are built with thick ceramic fiber insulation and powerful heating elements. This design ensures the entire chamber reaches and maintains a uniform temperature, guaranteeing that every part of the sample is ashed completely and consistently.

A Contaminant-Free Environment

The term "muffle" refers to the inner chamber, which isolates the sample from direct contact with the heating elements. This prevents contaminants from the heating elements from flaking off and spoiling the sample, which is critical when measuring elements at trace or ultra-trace levels.

Precise and Repeatable Control

Modern muffle furnaces feature intelligent controllers that allow for precise temperature ramping, holding, and cooling. This ensures that every sample is processed under identical conditions, a cornerstone of scientific reproducibility and quality control.

Understanding the Trade-offs and Considerations

While highly effective, ashing in a muffle furnace is not without its limitations. Understanding these is key to generating valid analytical data.

Risk of Volatilization

The primary risk is the loss of volatile elements. Certain metals and metalloids, such as mercury (Hg), arsenic (As), and selenium (Se), can turn into vapor at typical ashing temperatures and be lost. This would lead to an erroneously low measurement.

Time and Energy Consumption

Ashing is not an instantaneous process. Depending on the sample size and type, it can take several hours to complete. The high temperatures also demand significant electrical energy, though modern insulation has greatly improved efficiency.

Destructive Nature of the Technique

It is essential to recognize that ashing is a completely destructive technique. The original organic structure of the sample is permanently eliminated. This method is only suitable when the analysis is focused exclusively on the inorganic components.

Making the Right Choice for Your Goal

The decision to use a muffle furnace must be based on your specific analytical objective.

- If your primary focus is analyzing non-volatile trace metals (e.g., iron, copper, calcium): Muffle furnace ashing is the gold-standard pretreatment method for its simplicity and effectiveness.

- If your primary focus is analyzing volatile elements (e.g., mercury, arsenic, lead): You must either use a modified, lower-temperature ashing protocol or consider an alternative method like wet digestion with acids to prevent analyte loss.

- If your primary focus is analyzing the organic compounds (e.g., proteins, metabolites, drugs): Muffle furnace ashing is entirely unsuitable, as its sole purpose is to destroy these very components.

Ultimately, selecting the correct sample preparation technique is as crucial as the final analysis itself for achieving accurate and meaningful results.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Function | Ashing to remove organic material and isolate inorganic residues for analysis |

| Typical Temperature Range | 450°C to 550°C or higher |

| Analytical Techniques Supported | Atomic Absorption Spectroscopy (AAS), Inductively Coupled Plasma (ICP) Spectrometry |

| Key Benefits | Uniform heating, contaminant-free environment, precise temperature control for reproducibility |

| Limitations | Risk of volatile element loss, time and energy consumption, destructive to organic components |

| Ideal Use Cases | Analysis of non-volatile trace metals like iron, copper, and calcium in medical samples |

Unlock Precision in Your Medical Sample Analysis with KINTEK

Struggling with accurate trace element measurements in your lab? KINTEK's advanced high-temperature furnace solutions are engineered to meet the rigorous demands of medical sample pretreatment. Our muffle furnaces deliver uniform heating, contaminant-free environments, and precise temperature control—ensuring reliable ashing for superior inorganic analysis.

Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor solutions to your unique experimental needs, enhancing efficiency and data accuracy.

Ready to elevate your laboratory's performance? Contact us today to discuss how our furnaces can optimize your sample preparation process and drive better results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control