A box furnace, also known as a muffle furnace, is a type of industrial or laboratory oven with a simple, box-shaped chamber. It is designed for batch processing, where materials are manually loaded, heated in a static position, and then removed through a single front-facing door. Its primary function is to provide a highly controlled and uniform heating environment for various thermal processes.

A box furnace is a fundamental tool for heat treating materials in batches. Its value lies not in speed or volume, but in its ability to deliver precise, uniform temperature control, making it a versatile and reliable choice for enhancing material properties in labs and specialized production settings.

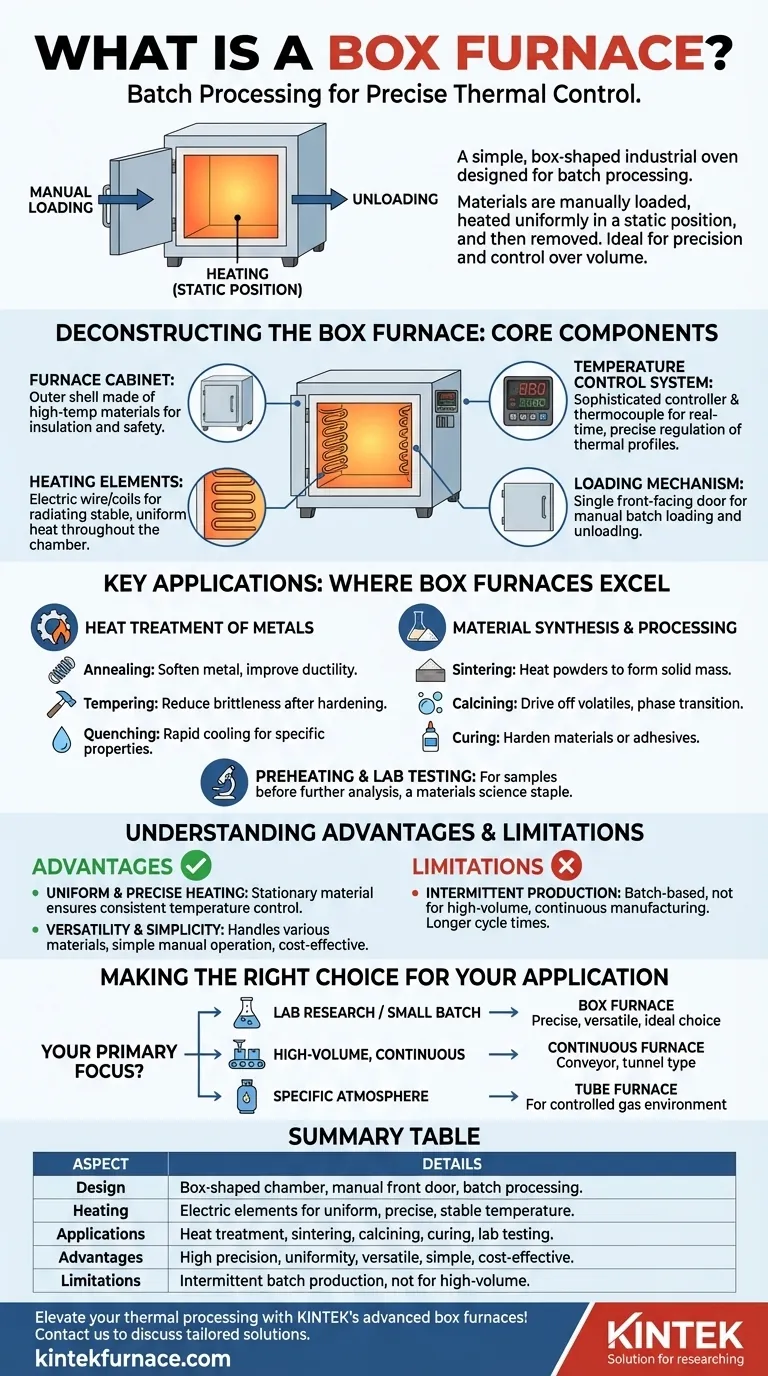

Deconstructing the Box Furnace: Core Components and Function

The design of a box furnace is straightforward, centered around a few key components working together to create a stable thermal environment.

The Furnace Cabinet

The cabinet, or furnace body, is the outer shell. It is built from high-temperature, heat-resistant materials that provide insulation, contain the heat, and ensure the exterior remains safe for operators.

The Heating Element

At the core of the furnace are the heating elements, which typically use electric heating wire or coils. These are strategically placed to radiate heat throughout the chamber, providing the stable and uniform temperatures necessary for consistent results.

The Temperature Control System

This is the furnace's most critical system for precision work. A modern box furnace uses a sophisticated controller and thermocouple to regulate temperature in real time, allowing operators to execute specific heating, soaking, and cooling profiles required by different processes.

The Loading Mechanism

The defining operational feature is its single door or slot for manual loading and unloading. This simple mechanism makes it an intermittent or batch production furnace, where one cycle must be completed before the next can begin.

Key Applications: Where Box Furnaces Excel

Box furnaces are valued for their versatility across a wide range of scientific and industrial applications that require precise thermal modification of materials.

Heat Treatment of Metals

This is a primary use, involving processes that alter the physical properties of metals. Common applications include:

- Annealing: Heating and slowly cooling to soften metal and improve ductility.

- Tempering: Heating to a specific temperature after hardening to reduce brittleness.

- Quenching: Rapidly cooling a workpiece to achieve certain material properties.

Material Synthesis and Processing

Box furnaces are also essential for creating or preparing non-metallic materials.

- Sintering: Heating powdered materials below their melting point to form a solid mass.

- Calcining: Heating materials to drive off volatile substances or induce a phase transition.

- Curing: Using heat to harden a material or adhesive.

Preheating and Laboratory Testing

In many workflows, a box furnace is used to preheat samples or components before they undergo further processing or analysis. Its reliability makes it a staple in materials science labs.

Understanding the Advantages and Limitations

While highly effective, the box furnace is designed for a specific mode of operation. Understanding its trade-offs is crucial for selecting the right equipment.

Key Benefit: Uniform and Precise Heating

Because the material remains stationary inside the chamber, the furnace can achieve exceptionally uniform temperatures. Paired with a quality control system, this allows for the high precision required for sensitive heat treatments.

Key Benefit: Versatility and Simplicity

A single box furnace can handle a wide variety of materials and thermal processes. The manual, front-loading operation is simple, easy to learn, and requires minimal maintenance, making it a cost-effective and durable solution.

Primary Limitation: Intermittent Production

The batch-based nature of a box furnace is its main constraint. It is not suitable for high-volume, continuous manufacturing lines where parts must flow through a process without interruption. Loading, heating, cooling, and unloading all contribute to a longer cycle time per part compared to continuous furnaces.

Making the Right Choice for Your Application

Selecting the correct heating equipment depends entirely on your process requirements, volume, and goals.

- If your primary focus is lab research or small-batch production: The box furnace's precision, versatility, and ease of use make it the ideal choice.

- If your primary focus is high-volume, continuous manufacturing: You will need a conveyor, tunnel, or another type of continuous furnace to meet throughput demands.

- If your primary focus is processing under a specific atmosphere: A specialized tube furnace may be a better choice for maintaining a pure, controlled gas environment.

By understanding its role as a precise batch-processing tool, you can determine if the box furnace is the right solution for your thermal processing needs.

Summary Table:

| Aspect | Details |

|---|---|

| Design | Box-shaped chamber with manual front-loading door for batch processing |

| Heating | Electric elements for uniform, stable temperatures with precise control |

| Applications | Heat treatment (annealing, tempering), sintering, calcining, curing, lab testing |

| Advantages | High precision, uniform heating, versatility, simplicity, cost-effectiveness |

| Limitations | Intermittent production, not suitable for high-volume continuous processes |

Elevate your thermal processing with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature solutions. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored furnace solutions can enhance your material properties and lab efficiency!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance