At its core, a muffle furnace prevents contamination by physically isolating the sample from the heat source. It achieves this using a high-temperature chamber, or "muffle," that separates the material being heated from combustion byproducts like gases and ash, ensuring the sample's chemical integrity remains pristine.

The defining principle of a muffle furnace is indirect heating. By placing the sample in a sealed chamber that is heated externally, you eliminate any possibility of contamination from the fuel or heating elements, which is non-negotiable for high-purity applications.

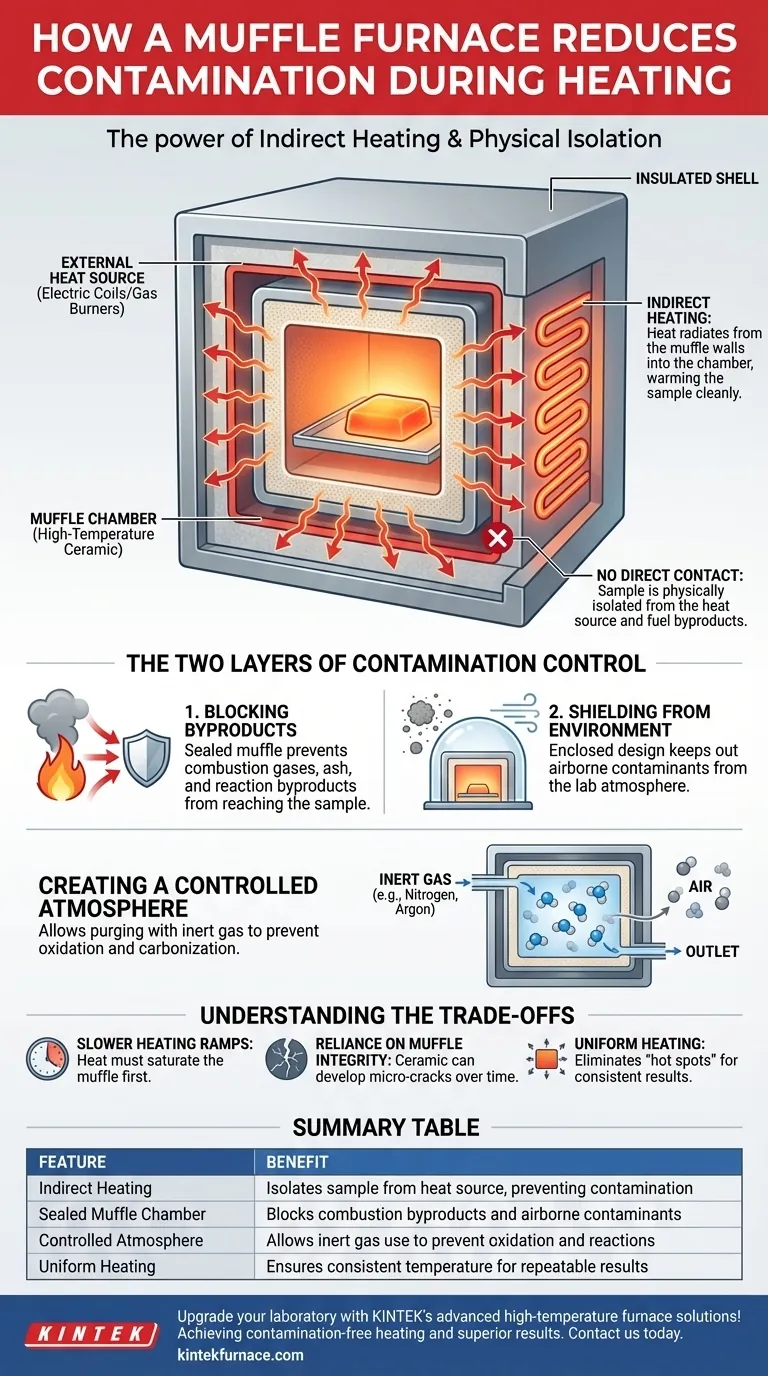

The Principle of Indirect Heating

The entire design of a muffle furnace is centered on one concept: separation. Unlike a simple kiln where a flame might directly touch the material, a muffle furnace creates a cleanroom-like heating environment.

What is a "Muffle"?

A muffle is an insulated inner chamber, typically made of high-temperature-resistant ceramic materials like alumina. This chamber holds the sample and acts as a barrier.

The heating elements, whether electric coils or gas burners, are located outside of this muffle. They heat the muffle itself, which then radiates that heat evenly and cleanly into the chamber, warming the sample.

Separating the Heat Source from the Sample

Think of it as cooking inside a sealed pot that is placed inside a larger oven. The food in the pot never touches the oven's heating elements.

This indirect transfer of heat is the mechanism that guarantees purity. The sample is only exposed to the clean, inert interior of the muffle and any controlled atmosphere you introduce.

The Two Layers of Contamination Control

This design provides a dual-layer defense against impurities, making it essential for sensitive scientific and industrial processes.

1. Blocking Byproducts from the Heat Source

In processes that use fuel for heat, combustion creates byproducts like gases and microscopic ash. If these particles land on or react with your sample, they alter its chemical composition.

A muffle furnace makes this impossible. The sealed muffle acts as an impenetrable shield, ensuring that only thermal energy—not physical contaminants—reaches your material.

2. Shielding from the External Environment

The enclosed design also prevents airborne contaminants from the surrounding lab or facility from entering the chamber and settling on the sample.

This is particularly critical when ashing samples for chemical analysis, where even a tiny speck of dust can skew results and compromise the integrity of your data.

Creating a Controlled Atmosphere

This separation also allows you to introduce a specific gas (like nitrogen or argon) into the muffle. By purging the ambient air, you can create an inert environment that prevents unwanted chemical reactions like oxidation or carbonization on sensitive materials.

Understanding the Trade-offs

While exceptional for purity, the muffle furnace design does come with inherent trade-offs that are important to acknowledge.

Slower Heating Ramps

Because the heat must first saturate the muffle before being transferred to the sample, muffle furnaces generally have slower heating and cooling rates compared to direct-heating methods. The muffle itself has thermal mass that needs to be overcome.

Reliance on Muffle Integrity

The effectiveness of the furnace is entirely dependent on the muffle remaining sealed and intact. Over time, with extreme thermal cycling, the ceramic can develop micro-cracks, potentially compromising the isolated environment. The muffle should be considered a high-performance, but ultimately consumable, component.

Uniform Heating as a Key Benefit

A significant advantage of this design is exceptionally uniform heating. Because the entire muffle radiates energy inward, it bathes the sample in heat from all directions.

This eliminates the "hot spots" common in direct-fire systems and ensures that the entire sample experiences the exact same temperature profile, leading to highly consistent and repeatable results.

Making the Right Choice for Your Application

Choosing the right furnace requires aligning its capabilities with your primary goal.

- If your primary focus is analytical accuracy: The muffle furnace is non-negotiable for preserving sample integrity during processes like ashing or trace metal analysis.

- If your primary focus is high-purity material processing: The controlled, isolated environment is essential for preventing oxidation and ensuring material quality.

- If your primary focus is rapid throughput above all else: A direct-heating furnace may be faster, but you must be willing to accept the significant risk of sample contamination.

Ultimately, the muffle furnace is the definitive tool for any thermal process where purity and precision cannot be compromised.

Summary Table:

| Feature | Benefit |

|---|---|

| Indirect Heating | Isolates sample from heat source, preventing contamination |

| Sealed Muffle Chamber | Blocks combustion byproducts and airborne contaminants |

| Controlled Atmosphere | Allows inert gas use to prevent oxidation and reactions |

| Uniform Heating | Ensures consistent temperature for repeatable results |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, helping you achieve contamination-free heating and superior results. Contact us today to discuss how we can enhance your processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating