Laboratory high-temperature furnaces serve as precise simulation tools for archaeometallurgy. By subjecting modern copper samples—chemically identical to ancient artifacts—to specific temperature gradients (typically 600–800°C), researchers can replicate the heat treatment processes of the past. This experimental approach generates a comparative dataset, allowing scientists to reverse-engineer the exact techniques early Bronze Age craftsmen used to manipulate metal.

The core value of these furnaces lies in comparative analysis: by reproducing the specific microstructures found in excavated artifacts, researchers can determine the precise temperatures originally used to eliminate work hardening and restore plasticity to the copper.

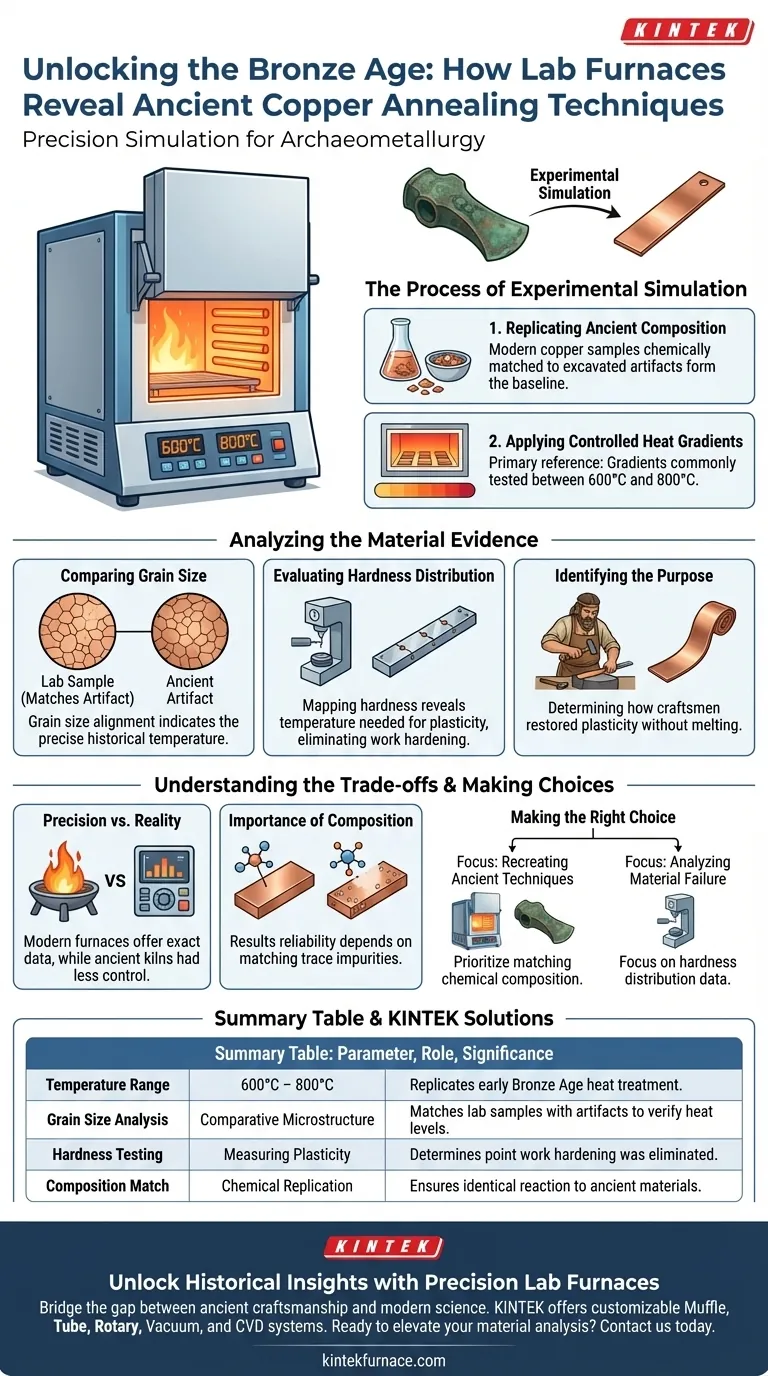

The Process of Experimental Simulation

Replicating Ancient Composition

The first step in determining annealing temperatures is establishing a baseline. Researchers must use copper samples that possess a chemical composition similar to the excavated artifacts.

This ensures that the material responds to heat in the laboratory exactly as the artifact would have during the Bronze Age.

Applying Controlled Heat Gradients

Once the appropriate samples are prepared, the high-temperature furnace is used to apply heat across a range of temperatures.

The primary reference notes that gradients between 600°C and 800°C are commonly used in these simulations. This creates a spectrum of heat-treated samples, each representing a different thermal history.

Analyzing the Material Evidence

Comparing Grain Size

Heat treatment alters the internal crystalline structure of copper. By comparing the grain size of the laboratory samples against the ancient artifact, researchers can identify a match.

When the grain sizes align, it indicates that the laboratory temperature matches the temperature achieved by the ancient craftsman.

Evaluating Hardness Distribution

In addition to visual microstructure, researchers measure the physical hardness of the metal. Annealing is specifically used to reduce hardness caused by working the metal.

By mapping the hardness distribution of the experimental samples, researchers can pinpoint the temperature required to achieve the specific level of plasticity found in the artifact.

Identifying the Purpose

The ultimate goal of this analysis is to understand the intent of the ancient smith.

The furnace data confirms how craftsmen managed work hardening—the brittleness that occurs when metal is hammered—and determined the optimal heat required to make the material pliable (plastic) again without melting it.

Understanding the Trade-offs

Precision vs. Reality

While high-temperature furnaces provide exact data, they represent an idealized environment. Ancient craftsmen worked with open fires or primitive kilns, which lacked the digital precision of modern laboratory equipment.

The Importance of Composition

The reliability of the results is entirely dependent on the "similar composition" of the test sample.

If the modern copper sample lacks specific trace impurities found in the Bronze Age artifact, the grain growth and hardness changes may not correlate perfectly, leading to potential inaccuracies in the temperature deduction.

Making the Right Choice for Your Goal

If your primary focus is recreating ancient techniques:

- Prioritize matching the chemical composition of your test samples to the artifact to ensure the furnace simulates the reaction accurately.

If your primary focus is analyzing material failure:

- Focus on the hardness distribution data to identify where the ancient annealing process may have been insufficient to eliminate work hardening.

By bridging modern control with ancient chemistry, high-temperature furnaces transform physical artifacts into historical data points.

Summary Table:

| Parameter | Role in Archaeometallurgy | Significance |

|---|---|---|

| Temperature Range | 600°C – 800°C | Replicates early Bronze Age heat treatment gradients. |

| Grain Size Analysis | Comparative Microstructure | Matches laboratory samples with artifacts to verify heat levels. |

| Hardness Testing | Measuring Plasticity | Determines the point where work hardening was successfully eliminated. |

| Composition Match | Chemical Replication | Ensures modern test samples react identically to ancient materials. |

Unlock Historical Insights with Precision Lab Furnaces

Bridge the gap between ancient craftsmanship and modern science with KINTEK. Whether you are researching archaeometallurgy or developing next-generation materials, our high-precision equipment provides the controlled environment needed for repeatable results.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to meet your unique research needs.

Ready to elevate your material analysis? Contact us today to find the perfect thermal solution for your laboratory.

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- How are muffle furnaces classified according to control devices? Choose the Right Control for Precision Heating

- What is the mechanism of a laboratory convection furnace for H13 DED steel? Mastering Heat Treatment Precision

- What role does a muffle furnace play in Pd1/CeO2 atom-trapping? Optimize Single-Atom Catalyst Synthesis

- What is the purpose of an ashing furnace? Essential for Accurate Ash Content Analysis

- What is the function of a laboratory high-temperature furnace in cook-off synthesis? A Precise Thermal Initiator

- How does heat distribution in drying ovens compare to muffle furnaces? Discover Key Differences for Your Lab