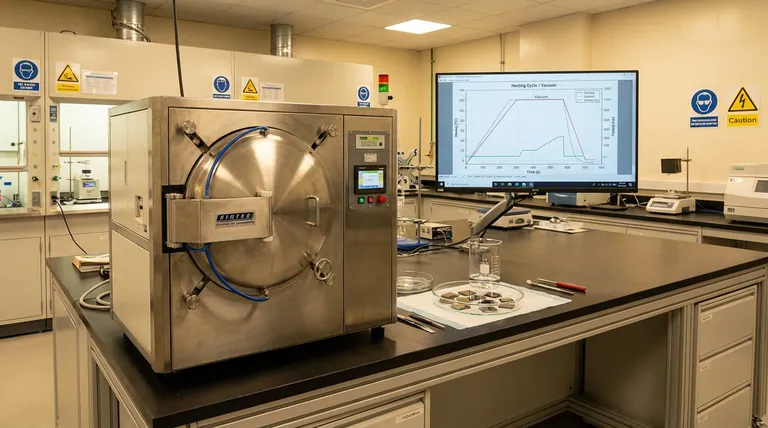

The primary function of a vacuum oven in the preparation of TiN/MoS2 composite coatings is to cure the Molybdenum Disulfide (MoS2) solid lubricant layer. This is achieved through a long-duration drying process at specific temperatures immediately after deposition. The vacuum environment facilitates the complete evaporation of solvents introduced during the alcohol dripping method, ensuring the final coating is chemically stable and mechanically sound.

Core Takeaway By removing solvents in a controlled vacuum environment, the oven transforms loose MoS2 micropowders into a cohesive, smooth solid film on top of the Titanium Nitride (TiN) layer. This curing step is non-negotiable for ensuring the lubricant adheres properly and provides a steady transition during the critical initial stages of friction.

The Mechanics of the Curing Process

The effectiveness of a composite coating relies heavily on how the solid lubricant integrates with the hard base layer. The vacuum oven addresses the deep need for structural integrity through two specific mechanisms.

Complete Solvent Evaporation

During the coating process, MoS2 micropowders are often deposited via an alcohol dripping technique. This introduces liquid solvents into the matrix that must be removed.

The vacuum oven is utilized to perform a long-duration drying cycle. This ensures that every trace of the solvent is fully evaporated from the coating layer.

Formation of a Solid Film

The removal of solvents is not merely about drying; it is about film formation. As the solvent evaporates, the MoS2 micropowders settle and densify.

This process creates a smooth and stable solid lubricating film. Without this step, the MoS2 would remain as a loose powder or unstable slurry, rendering it ineffective as a lubricant.

Why Vacuum Environments Are Superior

While a standard thermal oven can generate heat, the vacuum component adds critical physical advantages that improve the quality of the TiN/MoS2 composite.

Lower Temperature Efficiency

Vacuum environments significantly lower the boiling point of liquids. This allows solvents (such as alcohol) to evaporate rapidly and completely without requiring excessive temperatures.

This is crucial for maintaining the structural integrity of the coating. It prevents thermal shock or degradation that might occur if higher temperatures were required to drive off the solvent at standard atmospheric pressure.

Protection Against Oxidation

A vacuum oven operates by excluding oxygen and moisture from the chamber.

This prevents the oxidation of the coating materials during the heating phase. By maintaining a low-oxygen environment, the chemical purity of the MoS2 and TiN layers is preserved, ensuring the surface chemistry remains active for lubrication.

Impact on Tribological Performance

The ultimate goal of using the vacuum oven is to optimize the friction and wear characteristics of the final product.

Stabilizing the Friction Interface

The primary reference notes that this curing treatment allows for a steady transition during the initial friction stages.

Because the film is smooth and fully cured, it provides immediate lubrication. This prevents the "stick-slip" behavior or immediate coating failure that can occur with uncured or solvent-heavy layers.

Enhancing Layer Adhesion

The drying process ensures the MoS2 layer bonds effectively to the TiN hard layer.

By removing volatiles that could create voids or blisters, the vacuum oven ensures the lubricant layer remains attached to the hard substrate under mechanical stress.

Understanding the Trade-offs

While the vacuum oven is essential for quality, it introduces specific constraints to the manufacturing workflow.

Process Duration

The primary reference highlights that this is a "long-duration" drying process. Unlike flash-drying techniques, vacuum curing is time-intensive and can become a bottleneck in high-throughput manufacturing.

Complexity vs. Consistency

Vacuum systems add mechanical complexity compared to standard convection drying. However, this complexity is the trade-off required to achieve the necessary consistency and purity in the solid lubricant layer.

Making the Right Choice for Your Goal

The use of a vacuum oven is a calculated step to balance chemical purity with mechanical stability.

- If your primary focus is Durability: Prioritize the completeness of the drying cycle to ensure the MoS2 forms a dense, smooth film that will not shear off prematurely.

- If your primary focus is Consistency: Maintain strict temperature controls within the vacuum to prevent oxidation, ensuring that every batch exhibits the same friction transition properties.

The vacuum oven is not just a drying tool; it is the stabilizing phase that turns a mixture of powders and solvents into a high-performance functional coating.

Summary Table:

| Feature | Function in TiN/MoS2 Preparation | Benefit to Coating Performance |

|---|---|---|

| Solvent Evaporation | Removes alcohol from MoS2 micropowders | Ensures chemical stability and structural integrity |

| Film Formation | Cures loose powder into a cohesive solid film | Creates a smooth, steady transition for friction |

| Vacuum Environment | Lowers boiling points & excludes oxygen | Prevents oxidation and avoids thermal degradation |

| Adhesion Support | Eliminates volatiles and voids | Strengthens the bond between MoS2 and TiN layers |

Elevate Your Coating Precision with KINTEK

Don't let unstable films compromise your tribological performance. KINTEK’s advanced vacuum systems are engineered to provide the precise temperature control and high-vacuum environments necessary for superior TiN/MoS2 composite preparation.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your lab's unique high-temperature research needs. Whether you are optimizing solid lubricants or developing complex thin films, our technology ensures chemical purity and mechanical consistency.

Ready to refine your deposition process? Contact KINTEK today for a custom consultation!

References

- Hongyu Li, Shusheng Xu. Enhanced Friction and Wear Properties of TiN/MoS2 Composite Coating on the Surface of Plasma Nitrided Ti6Al4V Alloy. DOI: 10.3390/lubricants13010037

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of utilizing a high vacuum system and vacuum sealing? Ensure Purity in Alloy Synthesis

- What are the size ranges and common applications of crucible furnaces? Find Your Perfect Fit for Small-Batch Melting

- What are the functions of a heat shield in a vacuum sintering furnace? Essential for Thermal Control and Efficiency

- What is the role of the Discrete Ordinates (DO) model in vacuum furnace simulation? Master Radiative Heat Transfer

- What is the contamination of the vacuum furnace? Master Prevention for Flawless Results

- How do vacuum furnaces contribute to the medical and pharmaceutical industries? Ensure Purity and Biocompatibility

- Why is vacuum tempering considered faster than other methods? Discover the Key Speed and Efficiency Benefits

- Why is vacuum furnace brazing popular? Achieve Strong, Clean Joints for High-Performance Applications