In the medical and pharmaceutical industries, the primary contribution of vacuum furnaces is the production of exceptionally pure, strong, and biocompatible materials and devices. By creating a high-temperature, contamination-free environment, they enable the manufacturing of critical components like orthopedic implants and surgical tools that meet the stringent safety and performance standards required for use within the human body.

The core challenge in manufacturing medical-grade materials is preventing any reaction with the atmosphere, which introduces impurities and weakens the final product. Vacuum furnaces solve this fundamental problem by removing the air, ensuring that heat treatment processes enhance material properties without compromising their purity or biocompatibility.

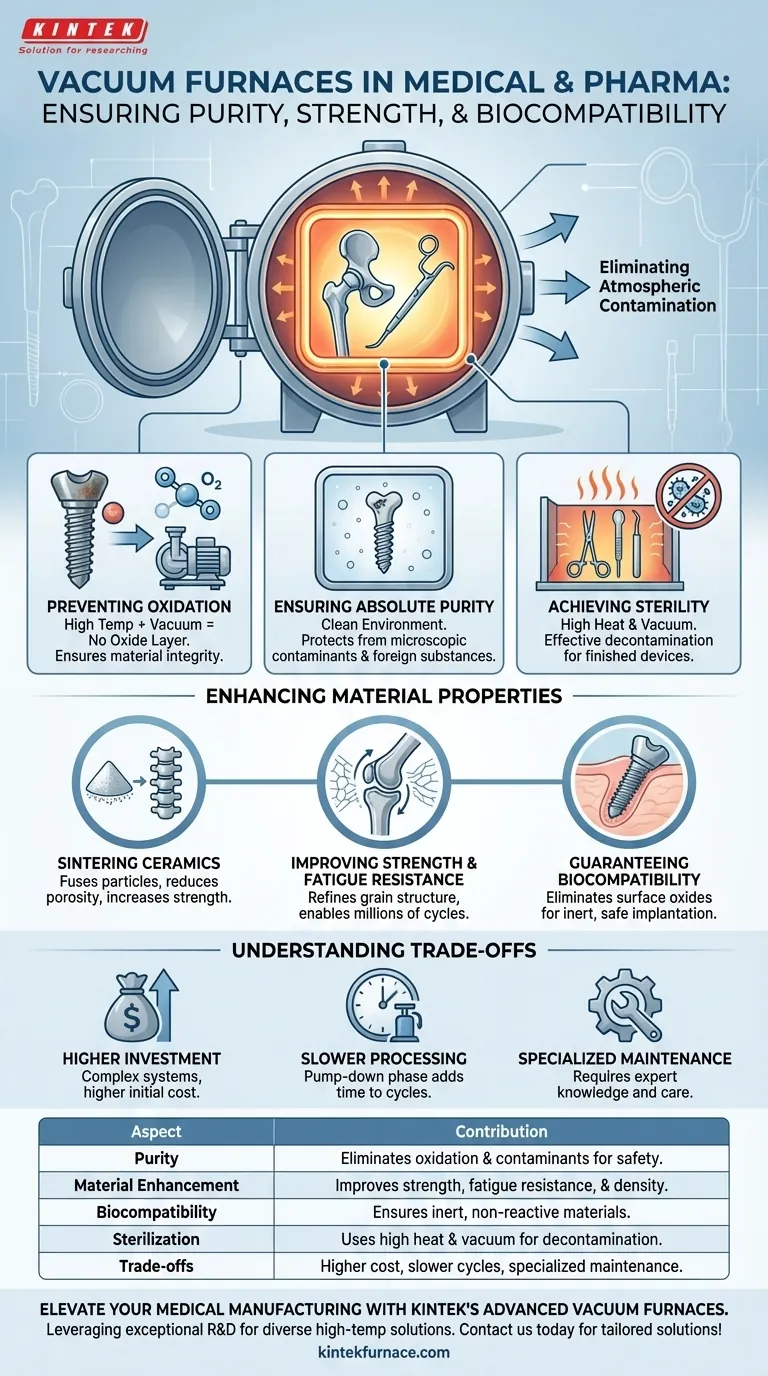

The Core Principle: Eliminating Atmospheric Contamination

The defining feature of a vacuum furnace is its ability to heat materials in an environment below atmospheric pressure. This seemingly simple change has profound implications for medical manufacturing.

Preventing Oxidation

At high temperatures, most metals react with oxygen in the air. This process, oxidation, can create a brittle oxide layer on the surface of a medical implant or instrument, compromising its strength and integrity. A vacuum environment contains virtually no oxygen, completely preventing this harmful reaction.

Ensuring Absolute Purity

The human body is extremely sensitive to foreign substances. Even microscopic contaminants introduced during manufacturing can lead to implant rejection or adverse immune responses. A vacuum furnace provides an inherently clean processing chamber, safeguarding materials from airborne particles and other impurities.

Achieving Sterility

The combination of high heat and a vacuum environment is a powerful tool for sterilization. This process ensures that finished medical devices like surgical instruments are free from any microorganisms before they are packaged and sent to a hospital.

Enhancing Material Properties for Medical Devices

Beyond just preventing contamination, vacuum furnaces are used to fundamentally improve the materials themselves, making them stronger, denser, and more durable.

Sintering High-Purity Ceramics

Advanced ceramics like silicon nitride are used in biomedical applications for their strength and wear resistance. Vacuum sintering is a process that heats ceramic powder to just below its melting point, causing the particles to fuse together into a solid, dense object. This process reduces porosity to almost zero, dramatically increasing the material's strength and reliability for use in spinal or joint implants.

Improving Strength and Fatigue Resistance

For metallic implants, such as titanium hip joints, vacuum heat treatment refines the metal's internal grain structure. This results in a superior combination of strength and fatigue resistance, ensuring the implant can withstand millions of cycles of movement over its lifetime without failing.

Guaranteeing Biocompatibility

Biocompatibility is the property of a material to exist in contact with bodily tissues without causing a harmful reaction. The purity achieved in a vacuum furnace is the single most important factor in guaranteeing biocompatibility. By eliminating surface oxides and embedded contaminants, the furnace ensures the final product is chemically inert and safe for long-term implantation.

Understanding the Trade-offs

While indispensable for high-quality outcomes, the use of vacuum furnaces involves specific considerations that are important to understand.

Higher Initial Investment

Vacuum furnaces are complex systems involving robust chambers, advanced heating elements, and sophisticated vacuum pumps. Their initial procurement cost is significantly higher than that of conventional atmospheric furnaces.

Slower Batch Processing

Each production cycle in a vacuum furnace requires a "pump-down" phase to remove the air from the chamber, which adds time. This makes batch processing inherently slower compared to continuous or open-air furnace operations.

Specialized Maintenance

The high-performance components of a vacuum furnace, particularly the vacuum seals, pumps, and control systems, require specialized knowledge for routine maintenance and repair. This adds to the operational overhead.

Making the Right Choice for Your Goal

When evaluating the role of vacuum furnaces, your decision should be guided by your primary objective.

- If your primary focus is patient safety and device reliability: Vacuum processing is the non-negotiable standard for critical implants and reusable surgical tools, as it is the only way to guarantee the required purity and material integrity.

- If your primary focus is manufacturing efficiency and cost: The higher initial cost and slower cycle times must be weighed against the significant long-term value derived from lower failure rates, fewer product recalls, and the ability to produce premium, high-margin medical devices.

- If your primary focus is material innovation: A vacuum furnace is an essential R&D tool for developing next-generation biomaterials, as it provides the pristine, controlled environment necessary to test and perfect new material compositions.

Ultimately, the use of vacuum furnaces is a foundational element in building trust between a medical device manufacturer, the clinician, and the patient.

Summary Table:

| Aspect | Contribution |

|---|---|

| Purity | Eliminates oxidation and contaminants for safe medical use. |

| Material Enhancement | Improves strength, fatigue resistance, and density via sintering. |

| Biocompatibility | Ensures materials are inert and non-reactive in the human body. |

| Sterilization | Uses high heat and vacuum to decontaminate devices effectively. |

| Trade-offs | Higher cost, slower processing, specialized maintenance required. |

Elevate Your Medical Manufacturing with KINTEK's Advanced Vacuum Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're producing orthopedic implants, surgical tools, or innovating biomaterials, our vacuum furnaces deliver the purity, strength, and reliability essential for patient safety and regulatory compliance.

Contact us today to discuss how our tailored solutions can enhance your production efficiency and product quality!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What are the applications of hot pressing? Achieve Maximum Material Performance