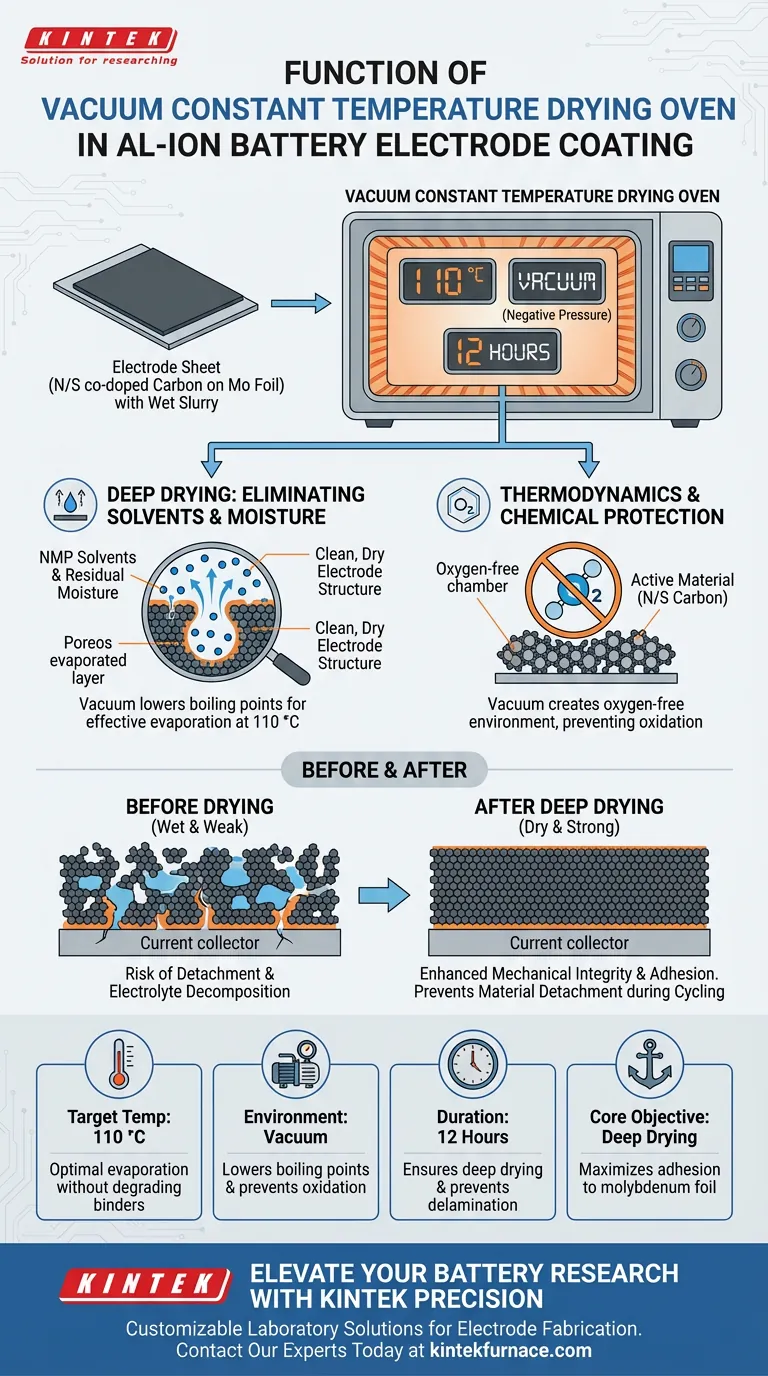

The primary function of a vacuum constant temperature drying oven in the electrode coating process for aluminum-ion batteries is to achieve deep drying of the cathode material, specifically nitrogen and sulfur co-doped carbon coatings applied to molybdenum foil.

By maintaining a consistent temperature of 110 °C under vacuum for 12 hours, this equipment ensures the complete removal of NMP (N-methyl-pyrrolidone) solvents and residual moisture. This specific thermal treatment is vital for enhancing the mechanical integrity of the electrode and ensuring the coating remains bonded to the current collector.

Core Takeaway: The vacuum drying oven acts as a critical stabilization stage. By thoroughly eliminating solvents and moisture without inducing oxidation, it maximizes the adhesion between the active material and the current collector, directly preventing material detachment during the rigorous charge-discharge cycles of the battery.

The Critical Role of Deep Drying

Eliminating Solvents and Moisture

The primary operational goal is the thorough removal of volatile components. In the context of aluminum-ion batteries using N/S co-doped carbon cathodes, the coating slurry contains NMP solvents which must be fully evaporated.

Standard drying is often insufficient to remove trapped solvent molecules from deep within the porous coating. The vacuum oven addresses this by creating a negative pressure environment that facilitates the evaporation of these stubborn residues.

Enhancing Mechanical Stability

The physical durability of the electrode is determined during this drying phase. If solvents or moisture remain, they compromise the interface between the active material and the molybdenum foil current collector.

By drying at 110 °C for an extended period (12 hours), the oven ensures the binder cures correctly. This strengthens the adhesion of the active layer, preventing the common failure mode where active substances detach or delaminate during battery cycling.

Operational Principles

The Vacuum Advantage

The use of vacuum is not merely about removing air; it is about thermodynamics and chemical protection.

First, the vacuum environment lowers the boiling point of solvents like NMP. This allows for effective evaporation at temperatures (like 110 °C) that are high enough to dry the material but controlled enough to preserve the electrode's microstructure.

Second, the vacuum creates an oxygen-free environment. While the primary reference focuses on solvent removal, supplementary data indicates that vacuum conditions prevent oxidation reactions between the active materials and air, ensuring chemical purity.

Precision Temperature Control

Uniformity is key to consistent battery performance. The "constant temperature" aspect ensures that the entire electrode sheet experiences the exact same thermal history.

For this specific application, 110 °C is the optimal set point. It provides enough thermal energy to drive out moisture and solvents without thermally degrading the active nitrogen and sulfur co-doped carbon material or the binder.

Understanding the Trade-offs

While vacuum drying is essential, it introduces specific constraints that must be managed:

Process Bottlenecks

The requisite drying time is significant. The specific protocol requires 12 hours of continuous drying. This makes the vacuum drying stage a potential bottleneck in high-throughput manufacturing compared to rapid, continuous drying methods.

Thermal Sensitivity

There is a delicate balance between drying speed and material integrity. Increasing the temperature above 110 °C might speed up solvent removal but runs the risk of damaging the binder or altering the doping structure of the carbon cathode. Conversely, lowering the temperature may leave residual NMP, leading to electrolyte decomposition or side reactions later.

Making the Right Choice for Your Goal

To optimize your electrode preparation process, align your drying parameters with your specific performance targets:

- If your primary focus is Cycle Life: Strictly adhere to the 12-hour duration at 110 °C to maximize adhesion and prevent the detachment of active substances during repeated cycling.

- If your primary focus is Chemical Purity: Ensure the vacuum seal is robust to prevent oxygen ingress, as this protects the N/S co-doped materials and prevents moisture-induced side reactions with the electrolyte.

Success in aluminum-ion battery fabrication relies not just on the materials chosen, but on the patience and precision applied during the drying phase to secure the electrode's structural foundation.

Summary Table:

| Parameter | Specification | Function/Benefit |

|---|---|---|

| Target Temp | 110 °C | Optimal evaporation of NMP without degrading binders |

| Environment | Vacuum (Negative Pressure) | Lowers solvent boiling points & prevents oxidation |

| Duration | 12 Hours | Ensures deep drying and prevents material delamination |

| Core Objective | Deep Drying | Maximizes mechanical adhesion to molybdenum foil |

Elevate Your Battery Research with KINTEK Precision

Precise thermal processing is the foundation of high-performance aluminum-ion batteries. At KINTEK, we specialize in providing advanced laboratory solutions tailored to your specific electrode fabrication needs.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces. Our vacuum constant temperature ovens are fully customizable to meet your unique drying protocols, ensuring your active materials remain pure and securely bonded to their current collectors.

Ready to eliminate solvent residues and boost cycle life?

Contact Our Experts Today to discuss your custom furnace requirements.

Visual Guide

References

- Jiahui Li, Shaobo Tu. Pseudocapacitive Heteroatom‐Doped Carbon Cathode for Aluminum‐Ion Batteries with Ultrahigh Reversible Stability. DOI: 10.1002/eem2.12733

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- Why is a high-vacuum heat treatment furnace necessary for vacuum annealing HEA coatings? Ensure Chemical Stability

- How does a vacuum oven contribute to processing solid residues in biomass fractionation? Ensure Sample Integrity

- How does a vacuum furnace ensure high-quality output? Achieve Superior Purity and Performance for Your Materials

- What are the key components of a vacuum annealing furnace? Master the Core for Superior Material Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why is a Spark Plasma Sintering (SPS) system superior to traditional furnaces? Speed and Density for Ceramics

- What is a vacuum sintering furnace and what is its primary function? Achieve High-Purity, Dense Materials

- What is the primary purpose of vacuum sealing raw materials for alpha-Mg3Bi2 crystal growth? Ensure Purity and Safety