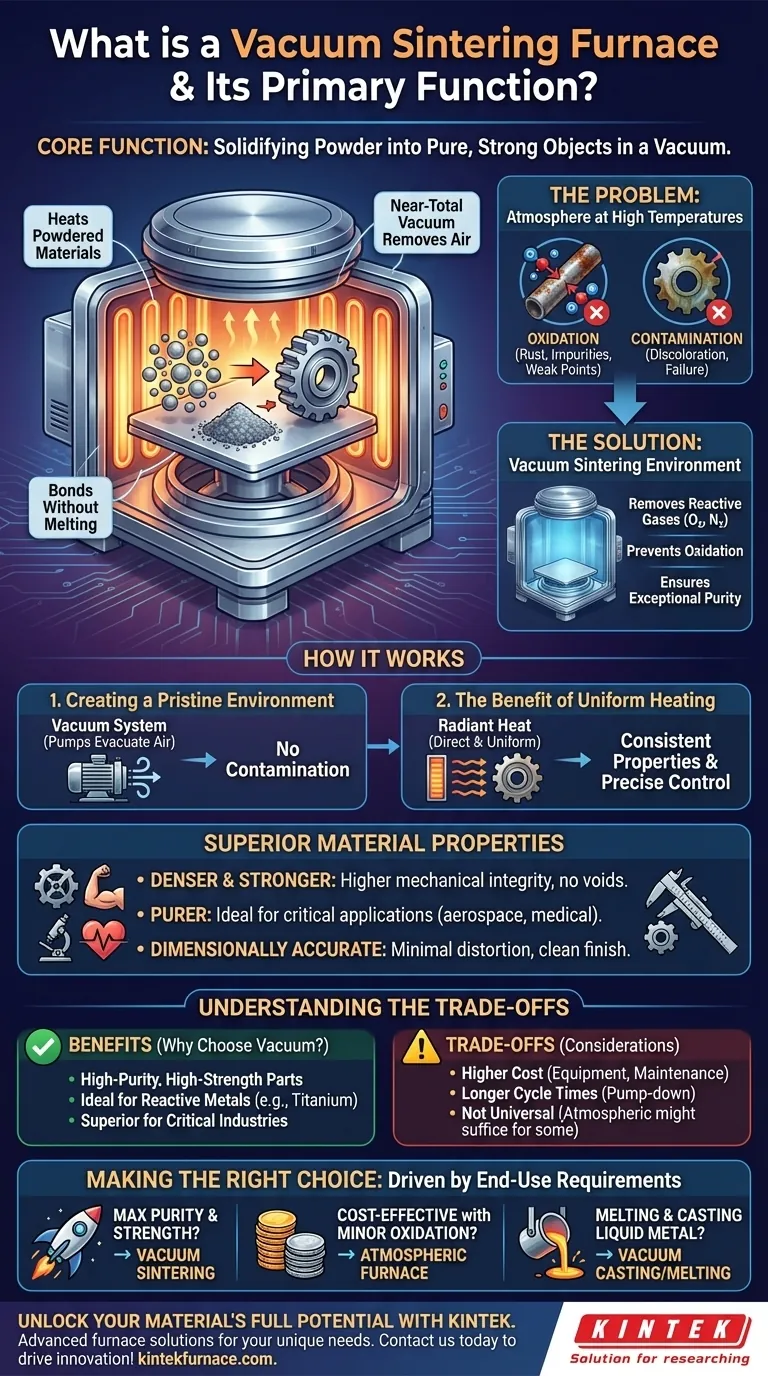

In essence, a vacuum sintering furnace is a specialized industrial oven that heats powdered materials to bond them into a solid, dense object without melting them. Its primary function is to perform this process in a near-total vacuum, which removes air and other reactive gases to prevent the material from oxidizing or becoming contaminated, ensuring the final product is exceptionally pure and strong.

The fundamental challenge in high-temperature manufacturing is that air, normally harmless, becomes highly reactive and corrupts the materials being processed. A vacuum sintering furnace solves this by removing the atmosphere entirely, creating a pristine environment to forge materials with properties unattainable through conventional methods.

The Core Problem: Why Atmosphere Matters in High-Temperature Processing

To understand the value of a vacuum furnace, you must first understand the problem it solves. At high temperatures, the oxygen and nitrogen in the air we breathe are no longer inert; they aggressively react with most materials.

The Threat of Oxidation and Contamination

When a material is heated in the presence of air, oxidation occurs. This is the same chemical reaction as rust forming on iron, but it happens almost instantly at sintering temperatures.

This reaction introduces impurities, creates weak points within the material's structure, and can lead to discoloration or outright failure of the final component. A vacuum environment physically removes these reactive gases.

Understanding the Sintering Process

Sintering is a thermal process for compacting and forming a solid mass of material from powder without melting it to the point of liquefaction.

Imagine pressing a handful of sand together—it remains loose. But if you heat it to a temperature just below its melting point, the individual grains will begin to fuse at their contact points. Sintering applies this principle to materials like metal powders, ceramics, and composites to create dense, solid parts.

How a Vacuum Furnace Enables Superior Sintering

A vacuum sintering furnace is engineered specifically to control the two most critical variables in this process: the atmosphere and the temperature.

Creating a Pristine Environment

The furnace's defining feature is its vacuum system. Before heating begins, powerful pumps remove the air from the sealed chamber. This evacuation prevents oxidation and contamination from atmospheric gases, which is critical for reactive metals like titanium or tungsten and for applications demanding the highest purity.

The Benefit of Uniform Heating

A vacuum is also an excellent thermal insulator. This property allows the furnace's heating elements to radiate heat directly and uniformly onto the part without interference from air currents. The result is exceptionally precise and stable temperature control, which is vital for achieving consistent material properties throughout the component.

The Result: Superior Material Properties

By eliminating unwanted chemical reactions and ensuring uniform heating, vacuum sintering produces parts that are:

- Denser and Stronger: With no voids or impurities from trapped gases, the final part has higher mechanical strength and integrity.

- Purer: The process is ideal for creating medical implants, aerospace components, and electronics where material purity is non-negotiable.

- Dimensionally Accurate: The controlled environment results in minimal distortion and a bright, clean surface finish, often reducing the need for post-processing.

Understanding the Trade-offs

While powerful, a vacuum sintering furnace is not always the necessary choice. Its advantages come with clear trade-offs.

The Cost of Purity

Vacuum furnaces are significantly more complex and expensive than their atmospheric counterparts. The need for robust vacuum chambers, high-performance pumps, and sophisticated control systems drives up both the initial investment and ongoing maintenance costs.

Longer Process Cycle Times

Achieving a deep vacuum is not instantaneous. The "pump-down" phase, where air is removed from the chamber before heating can begin, adds considerable time to the overall process cycle compared to a simple atmospheric furnace.

It Is Not a Universal Solution

For many materials and applications where minor surface oxidation is acceptable or can be removed later, the expense and complexity of a vacuum furnace are overkill. Simpler furnaces that use a protective gas atmosphere (like argon or nitrogen) can often provide a sufficient, more cost-effective solution.

Making the Right Choice for Your Goal

The decision to use a vacuum sintering furnace should be driven by the end-use requirements of the component you are creating.

- If your primary focus is producing high-purity, high-strength parts from powders (e.g., carbide tools, medical implants, aerospace-grade titanium): Vacuum sintering is the definitive choice to prevent contamination and achieve maximum density.

- If your primary focus is cost-effective production of materials where some surface oxidation is acceptable (e.g., certain steel parts): An atmospheric furnace or a simpler protective gas furnace is likely a more practical and economical solution.

- If your primary focus is melting and casting liquid metal into a mold: You need a vacuum casting or melting furnace, which is a different tool designed for liquid-phase processing, not solid-state sintering.

Ultimately, mastering the atmospheric environment is the key to unlocking the full potential of advanced materials.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Heats powdered materials in a vacuum to bond them into solid, dense objects without melting, preventing oxidation and contamination. |

| Key Benefits | Produces high-purity, strong, and dimensionally accurate parts; ideal for reactive metals and critical applications. |

| Common Applications | Used in aerospace, medical implants, electronics, and carbide tool manufacturing. |

| Trade-offs | Higher cost and longer cycle times compared to atmospheric furnaces; best for purity-critical needs. |

Unlock the Full Potential of Your Materials with KINTEK

Struggling with oxidation or contamination in your high-temperature processes? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements, delivering superior purity, strength, and efficiency for industries like aerospace, medical, and electronics.

Ready to enhance your lab's performance? Contact us today to discuss how our vacuum sintering furnaces can solve your material challenges and drive innovation!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness