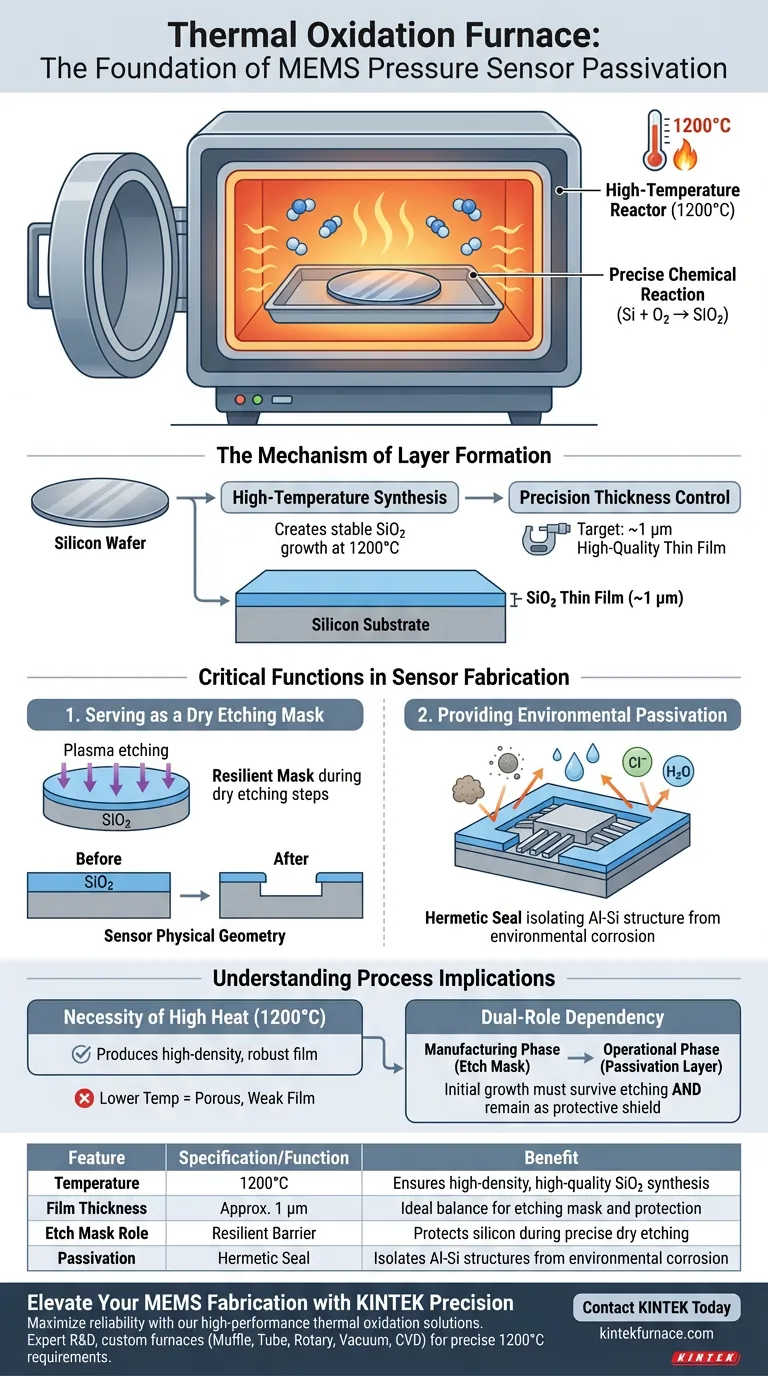

A thermal oxidation furnace functions as a high-temperature reactor, facilitating a precise chemical reaction between silicon and oxygen at 1200°C. This process grows a high-quality silicon dioxide ($\text{SiO}_2$) thin film, approximately 1 μm thick, which serves as both a manufacturing tool and a critical protective shield for MEMS pressure sensors.

By subjecting the wafer to extreme heat, the furnace creates a dual-purpose layer that acts as a robust mask during dry etching and a permanent passivation barrier, sealing the aluminum-silicon structure against environmental degradation.

The Mechanism of Layer Formation

High-Temperature Synthesis

The core function of the furnace is to create an environment where silicon can chemically bond with oxygen.

This reaction occurs at a temperature of 1200°C, ensuring a stable and uniform growth process.

Precision Thickness Control

The goal of this thermal cycle is to grow a specific thickness of silicon dioxide.

For MEMS pressure sensors, the target is a thin film of approximately 1 μm. This specific thickness is calculated to provide adequate structural integrity without compromising the sensor's mechanical properties.

Critical Functions in Sensor Fabrication

Serving as a Dry Etching Mask

Before the sensor becomes a finished product, it must undergo shaping processes.

The silicon dioxide layer grown in the furnace serves as a resilient mask during subsequent dry etching steps. It protects specific areas of the wafer while allowing others to be machined, defining the sensor's physical geometry.

Providing Environmental Passivation

Once fabrication is complete, the oxide layer transitions to its long-term role.

It acts as a passivation layer, effectively isolating the sensitive aluminum-silicon hybrid structure. This prevents environmental factors, such as moisture or contaminants, from corroding or altering the device's electrical characteristics.

Understanding the Process Implications

The Necessity of High Heat

The 1200°C requirement is not arbitrary; it is necessary to produce a "high-quality" film.

Lower temperatures might result in porous or mechanically weak oxides that fail to protect the underlying aluminum-silicon structure.

The Dual-Role Dependency

There is a critical dependency between the manufacturing phase and the operational phase.

Because the film acts as an etch mask first, the initial growth must be sufficient to survive the etching process and still leave enough material behind to serve as a protective passivation layer. If the initial growth is too thin, the device may lack adequate isolation in the field.

Ensuring Sensor Reliability

If your primary focus is Fabrication Efficiency: Ensure the oxide layer is grown to the full 1 μm thickness to withstand the aggression of dry etching processes without failing.

If your primary focus is Long-Term Reliability: Prioritize the high-temperature (1200°C) consistency to ensure the aluminum-silicon structure is hermetically sealed from environmental influences.

The thermal oxidation furnace is the foundational tool that transforms raw silicon into a durable, environment-resistant sensor interface.

Summary Table:

| Feature | Specification/Function | Benefit |

|---|---|---|

| Temperature | 1200°C | Ensures high-density, high-quality SiO2 synthesis |

| Film Thickness | Approx. 1 μm | Ideal balance for etching mask and protection |

| Etch Mask Role | Resilient Barrier | Protects silicon during precise dry etching |

| Passivation | Hermetic Seal | Isolates Al-Si structures from environmental corrosion |

Elevate Your MEMS Fabrication with KINTEK Precision

Maximize sensor reliability and fabrication yields with high-performance thermal oxidation solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temp lab furnaces designed for the precise 1200°C requirements of MEMS passivation.

Whether you need a specialized atmosphere for thin-film growth or a robust furnace for bulk processing, our engineering team is ready to tailor a solution to your unique research or production needs.

Contact KINTEK Today to Optimize Your Thermal Processes

Visual Guide

References

- Min Li, Wenhao Hua. Development of Highly Sensitive and Thermostable Microelectromechanical System Pressure Sensor Based on Array-Type Aluminum–Silicon Hybrid Structures. DOI: 10.3390/mi15091065

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the purpose of an atmosphere furnace? Control Gas Environments for Superior Material Processing

- How does a heating furnace contribute to the simulated pre-oxidation of alloy powders? Optimize Your Material Research

- What is the pressure range of an atmosphere box furnace under vacuum conditions? Find the Right Vacuum Level for Your Lab

- Why are inert ovens important in electronics manufacturing? Prevent Oxidation and Boost Component Reliability

- Why is a controlled atmosphere furnace required for 316L debinding? Ensure Structural Integrity & Zero Cracks

- Why are inert atmosphere furnaces important for graphite and carbon products? Prevent Oxidation and Ensure High-Performance Results

- Why is a protective atmosphere annealing furnace required for treating Alumina Dispersion Strengthened Copper (ADSC) rods after the hot extrusion process? Ensure Dimensional Stability and Oxidation-Free Results

- Why is a laboratory high-temperature furnace required for ML-MFC cathodes? Ensure Stable Pre-oxidation