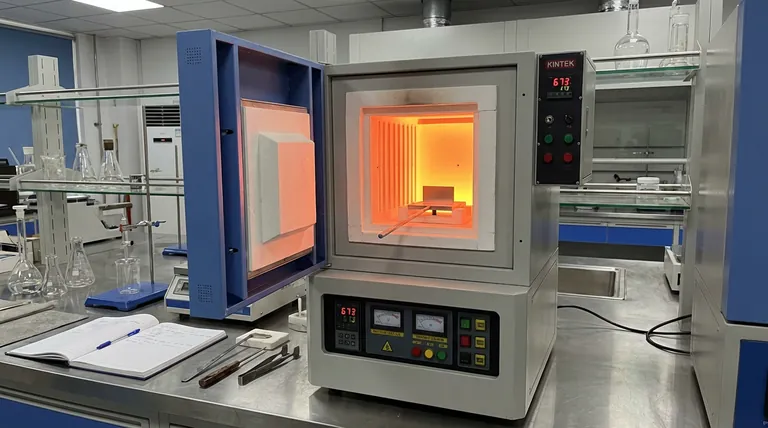

A laboratory high-temperature furnace is strictly required to create a controlled thermal environment—specifically maintaining 673 K for approximately 6 hours—to treat Membraneless Microbial Fuel Cell (ML-MFC) cathodes. This precise heating process facilitates the formation of a robust, stable oxide layer on the cathode surface, which is the critical factor in ensuring the component's performance does not deteriorate over time.

Core Takeaway The pre-oxidation treatment is not merely about heating; it is a stabilization process that locks in the cathode’s physicochemical properties. This thermal treatment prevents catalytic degradation, ensuring the electrode remains effective even when submerged in complex wastewater environments for extended periods.

The Mechanism of Stabilization

Creating the Protective Oxide Layer

The primary function of the high-temperature furnace in this context is to enable pre-oxidation. By exposing the cathode to 673 K for a sustained period (typically 6 hours), the furnace forces the surface of the alloy to react with oxygen.

This reaction results in a stable oxide layer. This layer acts as a chemical foundation that defines the electrode's future interaction with its environment.

Preventing Catalytic Degradation

Without this thermally induced oxide layer, the cathode is vulnerable. In the absence of pre-oxidation, the catalytic performance of the cathode tends to degrade rapidly.

The furnace treatment stabilizes the physicochemical properties of the alloy. This ensures that the material retains its ability to catalyze reactions efficiently, rather than losing activity shortly after operation begins.

The Role of Environmental Control

Ensuring Uniformity

A laboratory furnace is necessary because it provides a uniform temperature field. Unlike localized heating methods, a furnace ensures the entire cathode geometry is exposed to the exact same thermal conditions.

This uniformity is vital for creating a consistent oxide layer across the entire surface area of the electrode, preventing "weak spots" where degradation could begin.

Durability in Complex Environments

ML-MFCs are often deployed in wastewater, which is a chemically complex and harsh environment. The pre-oxidation treatment is specifically designed to prepare the cathode for these conditions.

By locking in the material properties through heat treatment, the furnace ensures the cathode possesses the long-term catalytic stability required to function in real-world waste streams without mechanical or chemical failure.

Understanding the Trade-offs

Process Time and Energy

The requirement for a 6-hour hold time at 673 K represents a significant energy and time investment in the fabrication process. This adds to the manufacturing complexity compared to non-treated cathodes.

Sensitivity to Temperature Precision

The success of this treatment relies heavily on the accuracy of the furnace. Deviating significantly from the target temperature (673 K) can lead to suboptimal results.

If the temperature is too low, the oxide layer may not form completely, leaving the cathode vulnerable. If the temperature is uncontrolled or excessive, it could alter the bulk material properties beyond the desired surface modification.

Ensuring Cathode Longevity

To maximize the performance of your Membraneless Microbial Fuel Cell, you must view the furnace treatment as a critical quality assurance step, not just a heating phase.

- If your primary focus is Long-Term Stability: Ensure the furnace maintains a strict 673 K profile for the full 6 hours to guarantee a complete and protective oxide layer.

- If your primary focus is Wastewater Application: Prioritize this pre-oxidation step to immunize the cathode against the chemical complexity of the waste stream, preventing early catalytic failure.

The high-temperature furnace is the gateway to transforming a raw alloy into a durable, chemically stable electrode capable of sustained operation.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Target Temperature | 673 K | Essential for forming a stable oxide layer |

| Holding Time | 6 Hours | Ensures uniform surface stabilization |

| Key Outcome | Protective Oxide Layer | Prevents catalytic degradation in wastewater |

| Critical Equipment | Lab High-Temp Furnace | Provides precise and uniform temperature fields |

Maximize Your Fuel Cell Durability with KINTEK

Don't let inconsistent heating compromise your research. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum systems that deliver the precise 673 K thermal environment required for ML-MFC cathode stabilization. Our customizable lab high-temperature furnaces ensure uniform pre-oxidation, protecting your electrodes against harsh wastewater conditions.

Ready to achieve superior catalytic stability? Contact us today to find your custom furnace solution!

References

- Paweł P. Włodarczyk, Barbara Włodarczyk. Effect of Using Various Cathode Materials (Carbon Felt, Ni-Co, Cu-B, and Cu-Ag) on the Operation of Microbial Fuel Cell. DOI: 10.59440/ceer/183171

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does airflow play in maintaining furnace atmospheres? Optimize Heat Treatment Quality

- What protective role does a constant flow of inert gas play in dynamic atmosphere sintering? Enhance Material Integrity

- What does nitrogen do in a furnace? Create an Inert, Oxygen-Free Atmosphere for Superior Results

- What is the function of an automatic cycling high-temperature box furnace in TCF testing? Expert Simulation Guide

- What factors determine the amount of gas flow required for furnace inerting? Optimize Your Process for Safety and Efficiency

- How does the controlled thermal environment of a laboratory furnace support the hydrothermal synthesis of NH2-MIL-125?

- What are the primary advantages of using atmosphere furnaces? Boost Material Quality and Cut Costs

- What are the different configurations available for inert atmosphere furnaces? Find Your Perfect Match for Heat Treatment