At its core, determining the gas flow for furnace inerting depends on three primary factors: the internal volume of the furnace, the furnace's inherent leak rate, and the process's required final oxygen level. The initial high-flow "purge" is calculated to displace the existing atmosphere, while a subsequent lower "maintenance" flow is set to counteract leaks and outgassing during the process.

The challenge isn't finding a single magic number for gas flow. The goal is to establish a dynamic balance where the inert gas displaces oxygen faster than air can leak back in, achieving this safely and cost-effectively for both the initial purge and the ongoing process.

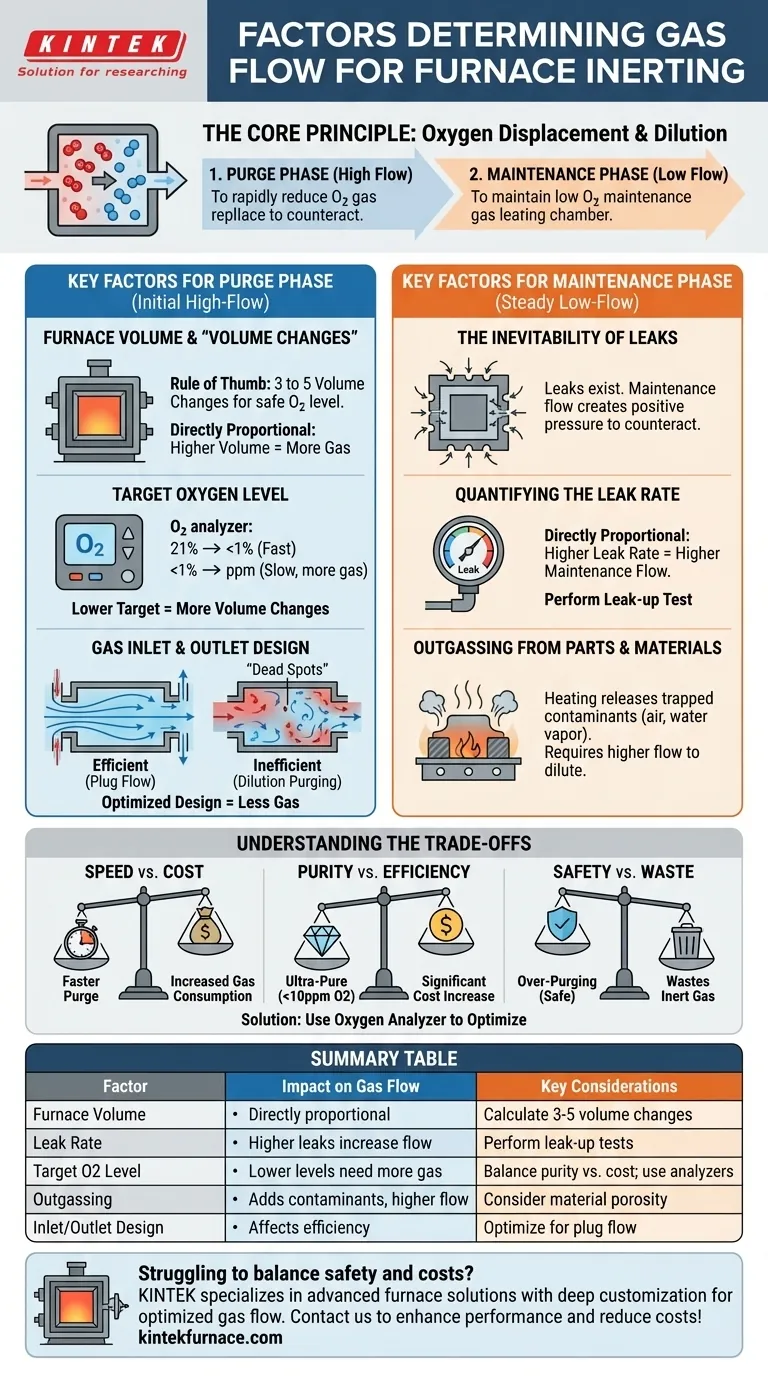

The Core Principle: Oxygen Displacement and Dilution

Furnace inerting is the process of replacing the ambient, oxygen-rich air inside a furnace with a dry, non-reactive gas like nitrogen or argon. This prevents unwanted oxidation, decarburization, or even explosive atmospheres during high-temperature operations.

The Two Phases of Inerting

The process is best understood in two distinct phases, each with its own flow rate requirement.

- The Purge Phase: This is the initial, high-flow stage designed to rapidly reduce the oxygen concentration from ~21% down to a safe or process-required level (often below 1%).

- The Maintenance Phase: Once the target oxygen level is reached, the flow is reduced to a lower, steady rate. This flow is designed only to compensate for ongoing gas losses and contamination.

Key Factors for the Purge Phase

The initial purge consumes the most gas and is critical for establishing the inert environment quickly.

Furnace Volume and "Volume Changes"

The single biggest factor is the internal volume of your furnace. The purge flow is often discussed in terms of furnace volume changes. One volume change is the amount of gas equal to the volume of the empty furnace.

As a rule of thumb, achieving a safe level of oxygen typically requires 3 to 5 volume changes. For example, a 100 cubic foot furnace would need 300 to 500 cubic feet of inert gas for an effective initial purge.

Target Oxygen Level

The lower your target oxygen level, the more volume changes you will need. Reducing oxygen from 21% to 1% is relatively fast. However, reducing it from 1% down to 100 parts per million (ppm) can require significantly more gas and time due to the nature of dilution.

Gas Inlet and Outlet Design

An efficient purge sweeps air out with minimal mixing, a concept known as plug flow. This is achieved with well-placed gas inlets (often low) and outlets (often high).

Poorly designed systems with "dead spots" or significant turbulence lead to dilution purging, which is far less efficient and requires much more gas to achieve the same result.

Key Factors for the Maintenance Phase

After the initial purge, the goal is simply to maintain the low-oxygen environment.

The Inevitability of Leaks

No furnace is perfectly sealed. Air will inevitably leak in through door seals, conveyor openings, thermocouple ports, and other fittings. The maintenance flow rate's primary job is to create positive pressure inside the furnace to overcome these leaks.

Quantifying the Leak Rate

The required maintenance flow is directly proportional to your furnace's leak rate. An older furnace with worn seals will require a much higher maintenance flow than a new, well-maintained unit to hold the same oxygen level. A leak-up test, where you measure the rate of oxygen increase after shutting off the gas, can help quantify this.

Outgassing from Parts and Materials

The components being heat-treated, as well as racks and fixtures, can release trapped air, water vapor, and other contaminants when heated. This outgassing introduces oxygen and requires a higher maintenance flow to dilute and remove the contaminants. Porous materials like certain ceramics are especially prone to this.

Understanding the Trade-offs

Choosing a flow rate involves balancing competing priorities. There is no single "correct" flow, only one that is optimal for your specific goals.

Speed vs. Cost

A higher purge flow rate will inert the furnace faster, reducing cycle time. However, this comes at the direct cost of increased nitrogen or argon consumption.

Purity vs. Efficiency

Achieving an ultra-pure atmosphere (<10 ppm O2) requires an exponentially higher amount of gas and time compared to a standard inert atmosphere (<1% O2). You must decide if the process benefit justifies the significant cost increase.

Safety vs. Waste

Under-purging is a serious safety hazard, potentially creating an explosive mixture of flammable process gas and air. To avoid this, many operators over-purge, which is safe but wastes a significant amount of inert gas. Using an oxygen analyzer is the only way to validate your purge and optimize flow.

Determining Your Required Gas Flow

Use these principles to guide your setup and operation.

- If your primary focus is maximum safety and quality: Start with a high purge rate calculated for 5 volume changes. Use a continuous oxygen analyzer to confirm you've reached your target O2 level before starting the process and to set a maintenance flow that holds that level steady.

- If your primary focus is cost optimization: Perform a leak-up test on the furnace to determine its specific leak rate. This will help you establish the absolute minimum maintenance flow required. Purge only until your target O2 level is met, not for a fixed time.

- If you are using a new or uncharacterized furnace: Be conservative. Begin with a high flow rate (e.g., 5 volume changes for purge) and a generous maintenance flow. Over several cycles, you can gradually reduce the flow rates while monitoring the oxygen levels to find the optimal balance for your process.

By understanding these influencing factors, you can move from guesswork to a deliberate and data-driven approach for achieving a reliable and efficient inert atmosphere.

Summary Table:

| Factor | Impact on Gas Flow | Key Considerations |

|---|---|---|

| Furnace Volume | Directly proportional; higher volume requires more gas for purge | Calculate based on 3-5 volume changes for initial purge |

| Leak Rate | Higher leaks increase maintenance flow to counteract air ingress | Perform leak-up tests to quantify and minimize flow |

| Target Oxygen Level | Lower levels need more gas due to dilution challenges | Balance purity needs with cost; use analyzers for precision |

| Outgassing | Adds contaminants, requiring higher maintenance flow | Consider material porosity and process temperatures |

| Gas Inlet/Outlet Design | Affects efficiency; poor design leads to higher flow needs | Optimize for plug flow to reduce mixing and waste |

Struggling to balance safety and costs in your furnace inerting process? At KINTEK, we specialize in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs. Let us help you optimize gas flow for reliable, efficient inerting—contact us today to discuss how our tailored solutions can enhance your lab's performance and reduce operational costs!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios