In furnace operations, airflow is the active mechanism for regulating the chemical and thermal environment within the heating chamber. It is not merely about circulation; it is a precise tool used to purge contaminants, ensure uniform temperature distribution, and deliver a consistent flow of a specific process gas to protect the integrity of the parts being treated. This active control is fundamental to achieving repeatable, high-quality results.

Inconsistent heat treatment is often traced back to a misunderstanding of the furnace atmosphere. The central principle is that airflow isn't just about containing a gas; it's about actively managing the entire thermal and chemical system to guarantee process stability and part quality.

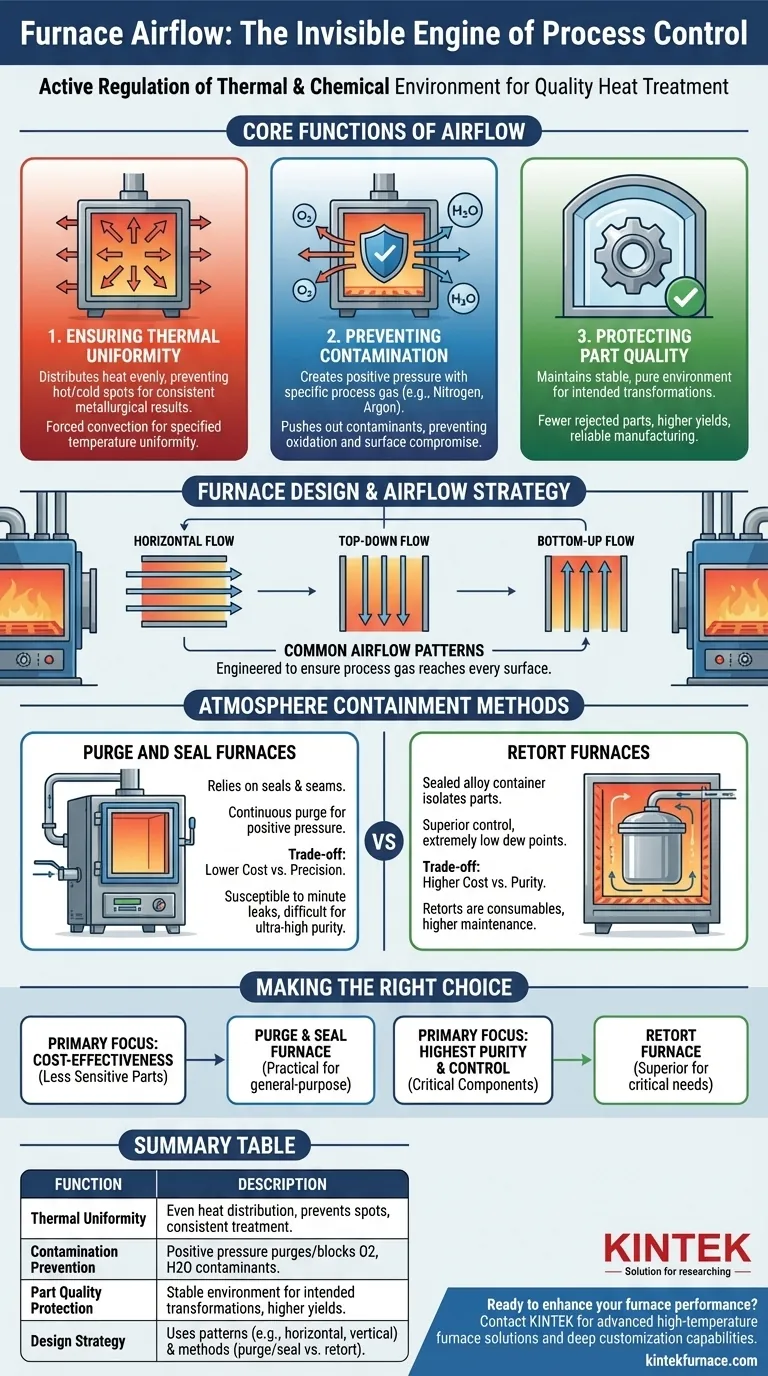

The Core Functions of Airflow in a Furnace Atmosphere

A controlled atmosphere is essential for most heat treatment processes. Airflow is the primary driver that makes this control possible, serving several critical functions simultaneously.

Ensuring Thermal Uniformity

Proper airflow is essential for distributing heat evenly throughout the furnace chamber. It prevents the formation of hot and cold spots, ensuring that all parts, regardless of their position, experience the same thermal profile.

This forced convection is what allows a furnace to achieve and maintain its specified temperature uniformity, which is critical for consistent metallurgical properties.

Preventing Contamination

A continuous, directed flow of a specific process gas (like nitrogen or argon) creates positive pressure inside the furnace. This pressure actively pushes out and prevents the ingress of contaminants such as oxygen and water vapor from the ambient air.

This "purging" action is the first line of defense against unwanted chemical reactions like oxidation, which can compromise the surface finish and structural integrity of the parts.

Protecting Part Quality

By creating a stable, pure, and thermally uniform environment, airflow directly protects the quality of the components being processed. It ensures that the intended metallurgical transformations occur as designed without interference from atmospheric impurities.

Ultimately, effective airflow management translates directly to fewer rejected parts, higher yields, and a more reliable manufacturing process.

How Furnace Design Dictates Airflow Strategy

The method of generating and containing the atmosphere profoundly impacts how airflow is managed. The physical design of the furnace dictates the strategy you must employ.

Common Airflow Patterns

Furnace designers use specific airflow patterns to optimize performance for different load configurations. Common patterns include:

- Horizontal Flow: Gas moves from one side of the chamber to the other.

- Top-Down or Bottom-Up Flow: Gas circulates vertically, which can be effective for baskets or stacked parts.

The choice of pattern is engineered to ensure the process gas reaches every surface of the parts being treated.

Atmosphere Containment Methods

Two primary design philosophies exist for containing the furnace atmosphere, each with a different approach to managing gas flow and purity.

- Purge and Seal Furnaces: These furnaces rely on tight door seals and welded case seams to minimize leaks. A continuous flow of gas purges the chamber and maintains positive pressure to keep contaminants out.

- Retort Furnaces: These designs use a sealed alloy container, or "retort," to hold the parts and the process atmosphere. This retort is then heated externally by the furnace.

Understanding the Trade-offs

The choice between a purge/seal design and a retort furnace involves a clear trade-off between cost, maintenance, and the level of atmospheric purity required.

The Purge and Seal Method: Economy vs. Precision

The main advantage of the purge and seal design is its lower initial cost and simpler construction. It is an economical and effective solution for many general-purpose heat treatment applications.

However, its primary limitation is in achieving very low dew points (a measure of water vapor). Because it relies on seals that can degrade over time, it is more susceptible to minute leaks, making ultra-high-purity atmospheres difficult to maintain.

The Retort Method: Purity vs. Cost

Retort furnaces offer superior atmospheric control. Because the parts are isolated within a fully sealed container, it is much easier to achieve and hold a very clean, high-purity atmosphere with extremely low dew points.

This high level of control comes at a price. Retort furnaces are more expensive to build and operate. The retorts themselves are consumables that require periodic maintenance and eventual replacement, adding to the overall operational cost.

Making the Right Choice for Your Process

Selecting the right furnace design is about aligning the equipment's capabilities with your specific process requirements and quality standards.

- If your primary focus is cost-effectiveness for less sensitive parts: A purge and seal furnace is a practical choice, provided its dew point limitations are acceptable for your process.

- If your primary focus is achieving the highest purity and atmosphere control for critical components: A retort furnace is the superior option, despite its higher initial cost and maintenance requirements.

By understanding these principles, you can transform airflow from a simple variable into your most powerful tool for process control and quality assurance.

Summary Table:

| Function | Description |

|---|---|

| Thermal Uniformity | Distributes heat evenly to prevent hot/cold spots and ensure consistent part treatment. |

| Contamination Prevention | Uses positive pressure to purge and block contaminants like oxygen and water vapor. |

| Part Quality Protection | Maintains a stable environment for intended metallurgical transformations and higher yields. |

| Design Strategy | Involves patterns (e.g., horizontal, vertical) and methods (purge/seal vs. retort) for optimal control. |

Ready to enhance your furnace performance with precise airflow control?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements.

Contact us today to discuss how our expertise can help you achieve superior process stability and part quality in your laboratory!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance