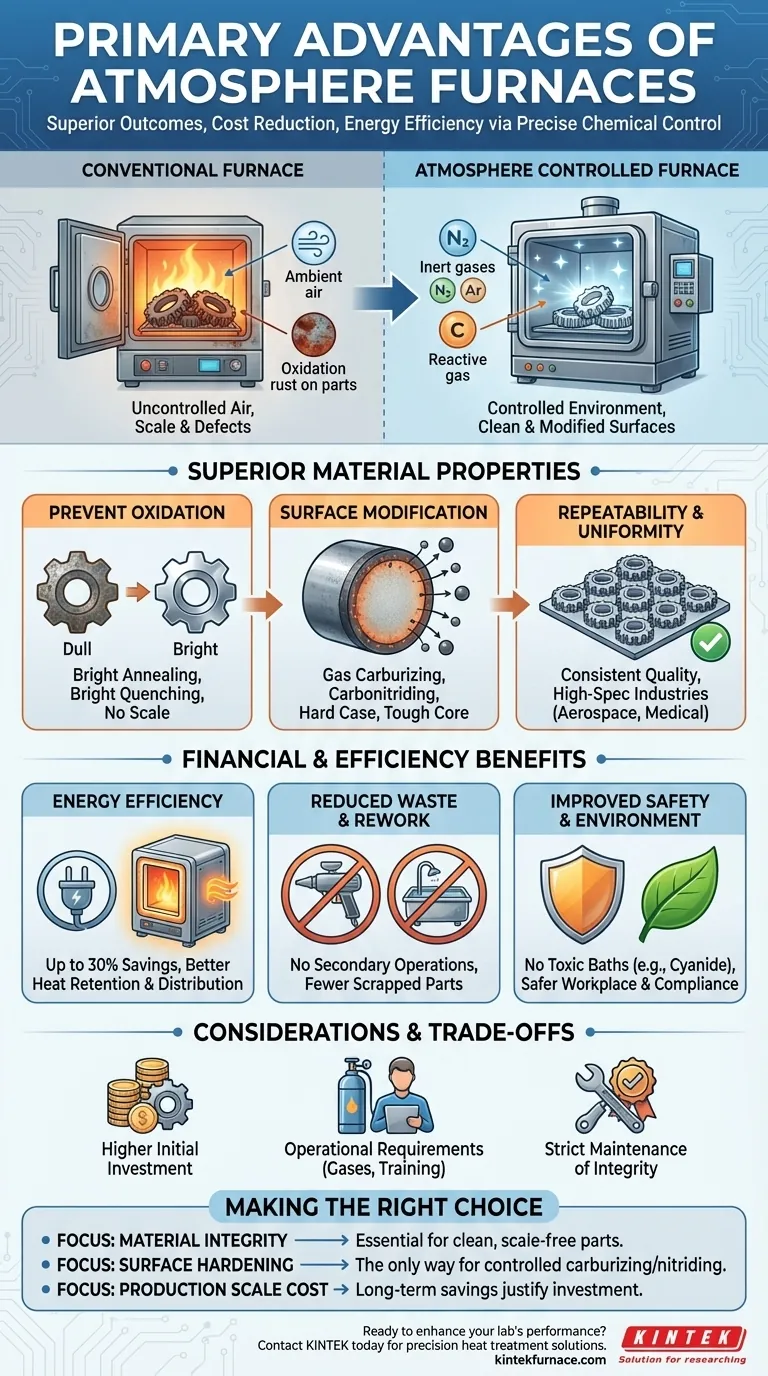

The primary advantages of using an atmosphere furnace are superior material outcomes, significant cost reduction, and high energy efficiency. Unlike conventional furnaces that heat materials in ambient air, an atmosphere furnace allows you to precisely control the chemical environment during the heating process. This control is the key that unlocks these three core benefits, preventing unwanted reactions like oxidation while enabling targeted surface enhancements.

An atmosphere furnace should be viewed not just as a tool for heating, but as a precision instrument for controlling chemical reactions at high temperatures. Its fundamental advantage lies in creating a controlled environment that protects materials from damage and allows for specific, desirable surface modifications.

How Atmosphere Control Unlocks Superior Material Properties

The most critical advantage of an atmosphere furnace is its ability to produce parts with higher quality, better performance, and greater consistency. This is achieved by managing the gases surrounding the material during heat treatment.

Preventing Oxidation and Surface Defects

In a conventional furnace, the oxygen in the air reacts with the hot metal surface, causing scale, discoloration, and decarburization (the loss of carbon from the surface of steel).

An atmosphere furnace prevents this by replacing the air with a protective, or inert, gas like nitrogen or argon. This purges the oxygen, allowing for processes like bright annealing and bright quenching, where parts emerge from the furnace clean and scale-free, requiring no subsequent cleaning.

Enabling Targeted Surface Modification

Beyond simply protecting the material, a controlled atmosphere can be used as an active ingredient to intentionally alter the material's surface properties.

This is the basis for case-hardening processes like gas carburizing and carbonitriding. By introducing a specific, carbon-rich atmosphere, you can diffuse carbon atoms into the surface of steel parts, creating a hard, wear-resistant outer layer while maintaining a softer, tougher core.

Ensuring Process Repeatability and Uniformity

The sealed, controlled environment of an atmosphere furnace leads to highly repeatable results. By precisely managing gas composition, pressure, and flow rates alongside temperature, you eliminate the variables that cause inconsistent outcomes in conventional furnaces.

This ensures that every part in a batch, and every subsequent batch, receives the exact same treatment, which is critical for high-specification industries like aerospace and medical device manufacturing.

The Financial Case: Efficiency and Cost Reduction

The technical superiority of atmosphere furnaces translates directly into measurable financial benefits through reduced operational costs and less waste.

Driving Energy Efficiency

Modern atmosphere furnaces are designed for excellent heat retention. The sealed chamber and specialized insulation minimize thermal loss.

Furthermore, the gases used can improve the efficiency of heat distribution. This optimization can lead to energy savings of up to 30% compared to older or conventional methods, significantly lowering operating expenditures.

Reducing Material Waste and Rework

Because atmosphere furnaces prevent scale and surface defects, the need for secondary operations like sandblasting, pickling, or machining is drastically reduced or eliminated.

This not only saves time and labor but also reduces the number of parts that are scrapped due to inconsistent heat treatment or surface damage.

Improving Environmental and Safety Conditions

Older methods of case hardening often involved toxic cyanide salt baths. Atmosphere furnaces eliminate the use of these hazardous materials.

This results in a safer working environment and removes the significant costs and liabilities associated with disposing of toxic waste, a clear advantage for both regulatory compliance and corporate responsibility.

Understanding the Trade-offs

While powerful, atmosphere furnaces are not a universal solution. Their advantages come with specific considerations that must be weighed.

Initial Investment and Complexity

Atmosphere furnaces are more complex than their conventional counterparts. They require sophisticated gas mixing panels, flow controls, and safety systems, which results in a higher upfront capital investment.

Operational Requirements

Operating an atmosphere furnace requires a reliable, and sometimes costly, supply of specific process gases (e.g., nitrogen, hydrogen, argon, endothermic gas). Operators also need specialized training to manage the gas systems and safety protocols safely and effectively.

Maintenance of Furnace Integrity

The core function of the furnace depends on its ability to remain sealed. Maintaining the integrity of door seals, thermocouples, and other fixtures is critical. Any leaks can compromise the atmosphere, leading to failed batches and potential safety hazards.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your material, your process, and your end goal.

- If your primary focus is material integrity and surface quality: An atmosphere furnace is essential for preventing oxidation and producing clean, bright parts that don't require post-processing.

- If your primary focus is surface hardening and wear resistance: An atmosphere furnace is the only way to perform modern, controllable processes like gas carburizing and nitriding.

- If your primary focus is cost reduction at production scale: The long-term savings in energy, labor, and reduced scrap rates will often justify the higher initial investment for an atmosphere furnace.

Ultimately, choosing an atmosphere furnace is a decision to invest in process control to achieve superior and more consistent material results.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Material Outcomes | Prevents oxidation, enables targeted surface modifications, and ensures consistent, high-quality parts. |

| Cost Reduction | Reduces material waste, minimizes rework, and lowers operational expenses through energy savings. |

| Energy Efficiency | Achieves up to 30% energy savings with sealed chambers and optimized heat distribution. |

| Environmental and Safety Benefits | Eliminates toxic materials, improves workplace safety, and aids regulatory compliance. |

Ready to enhance your lab's performance with precision heat treatment? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our atmosphere furnaces can deliver superior material properties, cost savings, and efficiency for your specific applications!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity