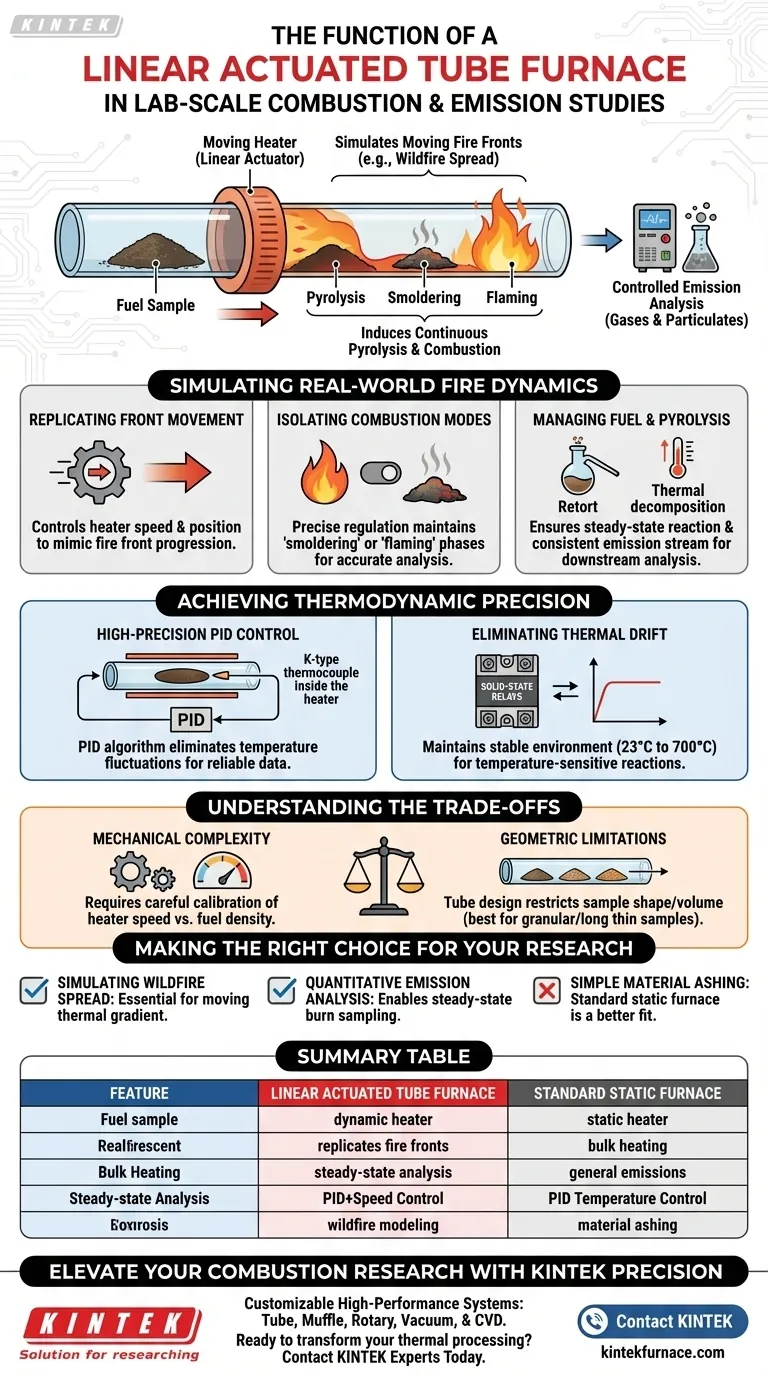

A linear actuated tube furnace system is a specialized laboratory instrument designed to replicate dynamic natural combustion processes, such as the spreading front of a wildfire. By using programmable controls to physically move a ceramic ring heater along a stationary fuel sample, this system allows researchers to induce continuous pyrolysis and combustion under highly controlled conditions. This capability is essential for isolating specific burning states—such as smoldering versus flaming—to perform quantitative analysis of the resulting emissions.

By transforming static heating into a dynamic process, this system provides the stability and control necessary to measure how moving fire fronts release chemical compounds and particulate matter.

Simulating Real-World Fire Dynamics

Replicating Front Movement

Standard laboratory furnaces generally heat a sample statically. In contrast, a linear actuated system introduces movement to simulate the natural progression of a fire.

By controlling the speed and position of the heater, researchers can mimic how a fire front consumes fuel over time.

Isolating Combustion Modes

Different stages of fire release different emissions. This system allows for the precise regulation of oxygen supply and temperature to sustain specific modes.

You can mechanically maintain a "smoldering" phase or a "flaming" phase for extended periods. This separation is critical for accurate, stage-specific emission analysis.

Managing Fuel and Pyrolysis

The system enables continuous pyrolysis (thermal decomposition) of materials.

By adjusting the movement speed relative to the fuel composition, the system ensures a steady-state reaction. This provides a consistent stream of emissions for downstream gas analyzers.

Achieving Thermodynamic Precision

High-Precision PID Control

To generate reliable data, temperature fluctuations must be eliminated. The system utilizes a Proportional-Integral-Derivative (PID) algorithm to manage the heating element.

This controller monitors real-time feedback from a K-type thermocouple located inside the heater.

Eliminating Thermal Drift

The PID controller dynamically regulates solid-state relays to maintain exact setpoints.

This mechanism ensures the environment remains stable within a typical range of 23°C to 700°C. This precision is vital for studying temperature-sensitive reaction pathways.

Understanding the Trade-offs

Mechanical Complexity

The addition of linear actuation introduces mechanical variables that do not exist in static box furnaces.

Users must calibrate the speed of the heater carefully against the density of the fuel. If the heater moves too fast, the fuel may not fully combust; too slow, and the "front" simulation is lost.

Geometric Limitations

The "tube" design inherent to these systems restricts the shape and volume of the sample.

While ideal for granular fuels, packed beds, or long thin samples, this geometry is less suitable for testing bulky, irregular objects that might block airflow or touch the heating elements.

Making the Right Choice for Your Research

To determine if a linear actuated tube furnace is the correct tool for your study, consider your specific analytical requirements:

- If your primary focus is simulating wildfire spread: This system is essential for replicating the moving thermal gradient of a fire front.

- If your primary focus is quantitative emission analysis: The ability to sustain a steady-state burn allows for the most accurate sampling of smoke components.

- If your primary focus is simple material ashing: A standard static muffle furnace is likely a more cost-effective and simpler solution.

This system is not just about generating heat; it is about controlling the geometry and timing of heat application to unlock deeper insights into combustion physics.

Summary Table:

| Feature | Linear Actuated Tube Furnace | Standard Static Furnace |

|---|---|---|

| Primary Motion | Dynamic moving heater (Linear Actuator) | Static heating element |

| Combustion Simulation | Replicates moving fire fronts/spread | Bulk material heating |

| Emission Analysis | Steady-state, stage-specific (smoldering/flaming) | General composite emissions |

| Control Mechanism | PID Control + Speed Calibration | Standard PID Temperature Control |

| Best Use Case | Wildfire modeling & emission kinetics | Material ashing & heat treatment |

Elevate Your Combustion Research with KINTEK Precision

Take control of your laboratory-scale fire dynamics and emission analysis. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique research parameters.

Whether you need precise linear actuation for simulating fire fronts or specialized high-temp furnaces for material science, our engineering team is ready to deliver the perfect solution for your lab.

Ready to transform your thermal processing? Contact KINTEK Experts Today

Visual Guide

References

- Casey Coffland, Elliott T. Gall. An open-source linear actuated-quartz tube furnace with programmable ceramic heater movement for laboratory-scale studies of combustion and emission. DOI: 10.2139/ssrn.5687995

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature tube furnace for Ce-MOF to CeO2 conversion? Guide to Precision Nano-Engineering

- How are tubular furnaces used in heat treatment processes? Unlock Precision in Material Science

- What role do industrial tube furnaces play in the oxidation of NiCrAl alloys? Precise Stability for Reliable Data

- What is the specific role of a tube furnace in the pre-treatment of activated carbon catalysts? Precision Modification

- What role does a Tube Furnace play in HDS catalyst de-oiling? Unlock Efficient Pyrolysis Recovery

- What is the significance of expanding raw material applicability in tube furnaces? Unlock Versatility and Cost Savings

- How are materials processed in a vacuum tube furnace? Master Controlled Heating for Purity and Precision

- Why is a high-temperature tube furnace used for AlPO4 calcination? Ensure Safety in Molten Salt Electrolysis