At their core, tubular furnaces are used in heat treatment to precisely modify the physical and chemical properties of materials. They accomplish this by heating samples within a cylindrical chamber to high temperatures under highly controlled conditions. This precision enables critical processes like annealing, hardening, tempering, and sintering for materials ranging from metals and alloys to advanced ceramics.

The primary reason tubular furnaces are chosen for sensitive heat treatments is their design, which provides exceptional temperature uniformity and a tightly controlled atmospheric environment. This makes them indispensable for applications where precision outweighs the need for sheer volume.

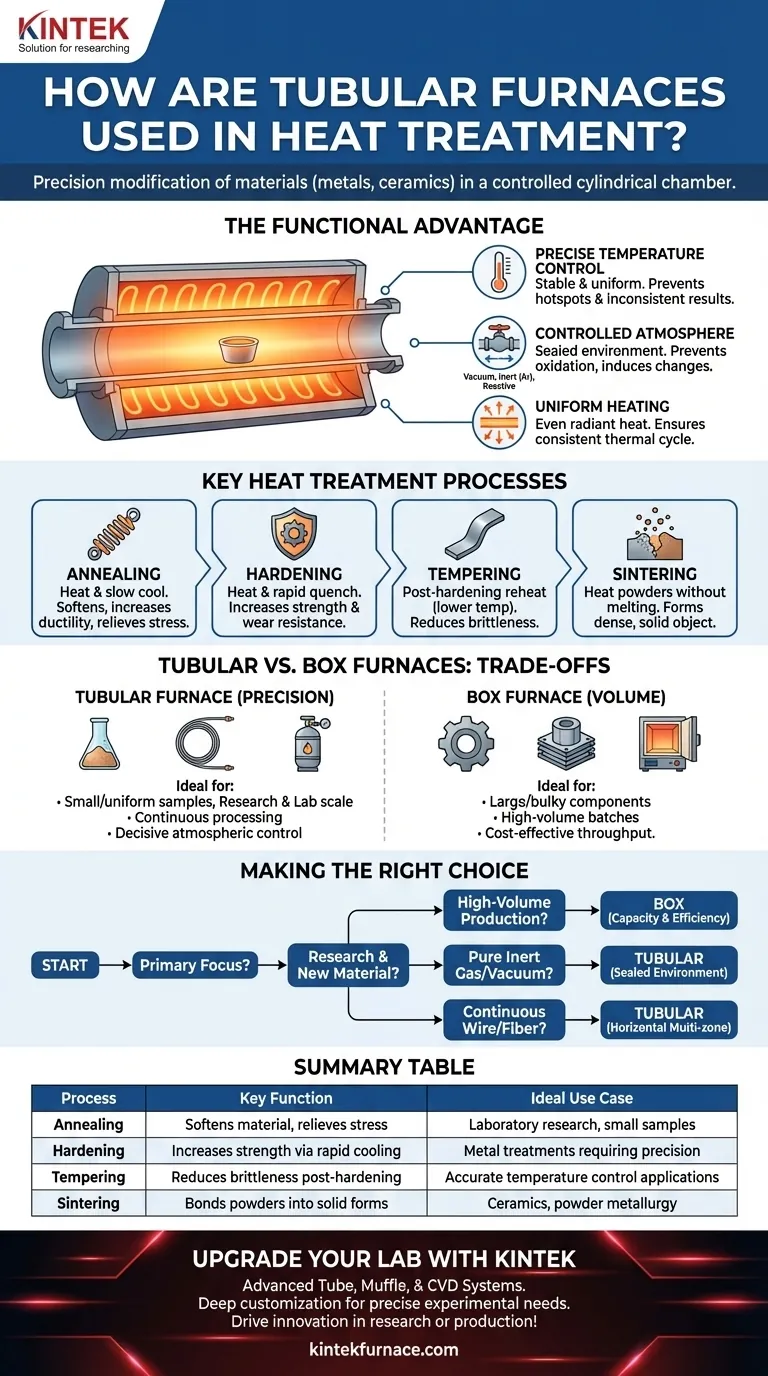

The Functional Advantage in Heat Treatment

The unique geometry of a tubular furnace is what makes it so effective. By placing heating elements around a cylindrical tube, it creates a "hot zone" of extremely consistent temperature, which is essential for achieving predictable results in material science.

Achieving Precise Temperature Control

The furnace's control system and the arrangement of its heating elements work together to maintain a stable, uniform temperature. This prevents hotspots or cold spots that could ruin a sample by causing inconsistent grain growth, internal stresses, or incomplete phase transitions.

Creating a Controlled Atmosphere

The tube can be easily sealed at both ends, allowing you to control the gaseous environment around the sample. You can create a vacuum to prevent oxidation, or you can introduce specific inert gases (like argon) or reactive gases to induce a chemical change on the material's surface. This capability is crucial for many advanced heat treatments.

Ensuring Uniform Heating

Because the sample is placed in the center of a cylindrical heating chamber, it receives radiant heat evenly from all directions. This uniform exposure is vital for ensuring that the entire workpiece, whether it's a small crucible of powder or a single crystal, undergoes the exact same thermal cycle.

Key Heat Treatment Processes Performed

Tubular furnaces are versatile tools capable of performing a wide range of heat treatments, each with a different goal.

Annealing

This process involves heating a material and then cooling it slowly to soften it, increase its ductility, and relieve internal stresses. The excellent temperature stability and programmable cooling rates of a tubular furnace make it ideal for this task.

Hardening

Hardening increases the strength and wear resistance of a metal by heating it above its critical temperature and then cooling it rapidly (quenching). A tube furnace provides the precise heating, after which the sample can be quickly removed for quenching.

Tempering

Performed after hardening, tempering reduces the brittleness of a metal by heating it to a lower, very specific temperature. The accuracy of a tubular furnace is paramount here, as even a small deviation can result in a failed part.

Sintering

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction. Tubular furnaces provide the uniform heat and controlled atmosphere needed to bond the particles of a powder together, forming a dense, solid object.

Understanding the Trade-offs: Tubular vs. Other Furnaces

While powerful, a tubular furnace is not the universal solution. Its capabilities overlap with other furnace types, and the choice depends on the specific application.

Volume and Geometry Constraints

Tubular furnaces are best suited for smaller samples or materials with a uniform shape, like powders, wires, or small parts. For treating large, bulky, or irregularly shaped components, a box or muffle furnace is often a more practical choice due to its larger, open chamber.

Batch vs. Continuous Processing

Box furnaces excel at processing large batches of parts simultaneously. In contrast, tubular furnaces are ideal for laboratory-scale work, material testing, or continuous processing of a single, long workpiece like a fiber or wire that can be fed through the tube.

When Atmospheric Control is Decisive

If your process is highly sensitive to oxygen or requires a specific reactive gas, a tubular furnace is almost always the superior choice. Its enclosed design is far easier and more cost-effective to seal and purge than the large chamber of a box furnace.

Making the Right Choice for Your Application

Selecting the correct furnace requires balancing your need for precision against你的 demands for scale and throughput.

- If your primary focus is research and new material development: A tubular furnace is the ideal choice for its unparalleled precision and atmospheric control with small samples.

- If your primary focus is high-volume heat treatment of many parts: A box furnace offers greater capacity and cost-efficiency for batch processing.

- If your primary focus is a process requiring a pure inert gas or vacuum: The sealed chamber of a tubular furnace provides the best environment for preventing contamination.

- If your primary focus is continuous treatment of a uniform material like a wire: A horizontal multi-zone tube furnace is specifically designed for this type of production.

Ultimately, the right furnace is the one whose capabilities HTMLScale, geometry, and atmospheric requirements of your specific material and process.

Summary Table:

| Process | Key Function | Ideal Use Case |

|---|---|---|

| Annealing | Softens material, relieves stress | Laboratory research, small samples |

| Hardening | Increases strength via rapid cooling | Metal treatments requiring precision |

| Tempering | Reduces brittleness post-hardening | Accurate temperature control applications |

| Sintering | Bonds powders into solid forms | Ceramics, powder metallurgy |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Tube Furnaces, Muffle Furnaces, and CVD/PECVD Systems. Our strong deep customization ensures precise fit for your unique experimental needs—whether for annealing, hardening, or sintering under controlled atmospheres. Contact us today to discuss how our expertise can enhance your heat treatment processes and drive innovation in your research or production!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab