The primary function of a laboratory muffle furnace in the preparation of Bismuth Vanadate (BiVO4) is to provide a strictly controlled high-temperature environment for calcination. By subjecting precursor materials to temperatures typically around 400 °C, the furnace drives essential chemical and structural transformations that determine the final material's quality.

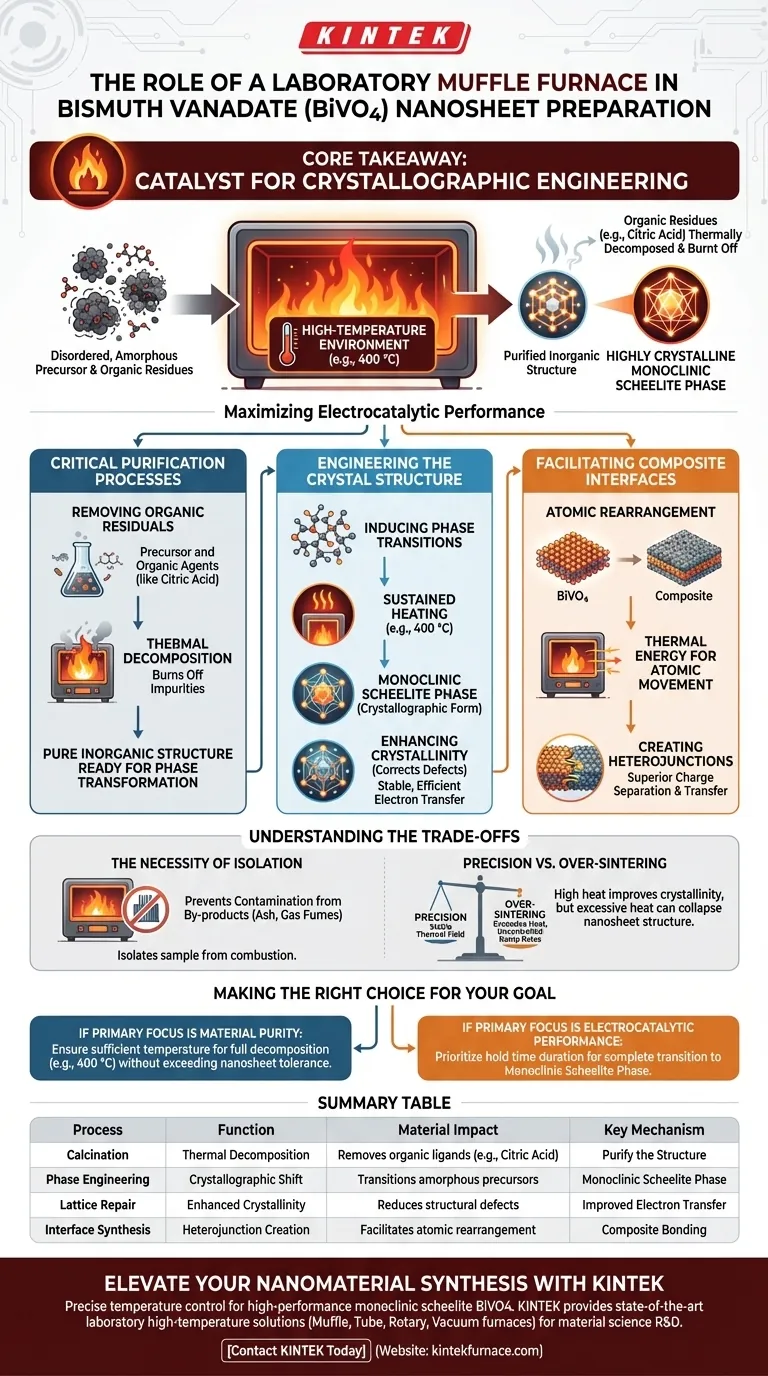

Core Takeaway The muffle furnace acts as the catalyst for crystallographic engineering. It converts BiVO4 from a disordered, amorphous precursor into a highly crystalline monoclinic scheelite phase, while simultaneously purifying the material by thermally decomposing organic residues to maximize electrocatalytic performance.

Critical Purification Processes

Removing Organic Residuals

During the initial synthesis of nanosheets, organic agents such as surfactants or ligands like citric acid are frequently used. These organics must be removed to prevent them from interfering with the material's activity.

Thermal Decomposition

The muffle furnace utilizes high temperatures to trigger thermal decomposition. This effectively burns off organic impurities, leaving behind a pure inorganic structure ready for phase transformation.

Engineering the Crystal Structure

Inducing Phase Transitions

The most definitive role of the furnace is shifting the material's state. Precursor BiVO4 often exists in a disordered, amorphous state prior to heating.

Achieving the Monoclinic Scheelite Phase

Through sustained heating (e.g., at 400 °C), the furnace forces the atomic structure to rearrange. This transitions the material into the monoclinic scheelite phase, which is the specific crystallographic form required for high-performance applications.

Enhancing Crystallinity

Heat treatment corrects defects within the crystal lattice. By improving the crystallinity of the BiVO4, the furnace ensures the material is stable and capable of efficient electron transfer, directly boosting its electrocatalytic performance.

Facilitating Composite Interfaces

Atomic Rearrangement

For composite materials involving BiVO4, the furnace provides the thermal energy needed for atomic movement. This facilitates atomic rearrangement at the boundary where different materials meet.

Creating Heterojunctions

This process is essential for constructing a heterojunction—a tight chemical bond between the BiVO4 and other composite components. A successful heterojunction allows for superior charge separation and transfer efficiency between materials.

Understanding the Trade-offs

The Necessity of Isolation

A key advantage of the muffle furnace is its design, which isolates the sample from combustion by-products. This prevents contamination from ash or gas fumes that could alter the delicate surface chemistry of the nanosheets.

Precision vs. Over-Sintering

While high heat improves crystallinity, the temperature profile must be managed precisely. The furnace maintains a stable thermal field to ensure uniformity. However, excessive heat or uncontrolled ramp rates can lead to over-sintering, which may collapse the nanosheet structure and reduce the specific surface area available for reactions.

Making the Right Choice for Your Goal

To optimize your Bismuth Vanadate preparation, align your furnace settings with your specific objectives:

- If your primary focus is material purity: Ensure your temperature is sufficient to fully decompose ligands like citric acid (typically around 400 °C) without exceeding the tolerance of the nanosheet structure.

- If your primary focus is electrocatalytic performance: Prioritize the duration of the hold time to ensure a complete transition to the monoclinic scheelite phase, as this specific crystal structure dictates catalytic activity.

Success relies on using the muffle furnace not just as a heater, but as a precision tool for phase engineering and molecular organization.

Summary Table:

| Process Function | Material Impact | Key Mechanism |

|---|---|---|

| Calcination | Thermal Decomposition | Removes organic ligands like citric acid to purify the structure |

| Phase Engineering | Crystallographic Shift | Transitions amorphous precursors to monoclinic scheelite phase |

| Lattice Repair | Enhanced Crystallinity | Reduces structural defects for improved electron transfer |

| Interface Synthesis | Heterojunction Creation | Facilitates atomic rearrangement for composite bonding |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise temperature control is the difference between a collapsed structure and a high-performance monoclinic scheelite BiVO4 nanosheet. KINTEK provides state-of-the-art laboratory high-temperature solutions—including Muffle, Tube, Rotary, and Vacuum furnaces—specifically engineered to meet the rigorous demands of material science R&D.

Whether you are performing delicate calcination or complex CVD processes, our customizable systems ensure the thermal uniformity your research deserves. Contact KINTEK today to discover how our expert manufacturing and R&D support can empower your next breakthrough.

Visual Guide

References

- Nokuthula Mekgoe, Kriveshini Pillay. Synergistic electrochemical detection of ciprofloxacin using bismuth vanadate nanocomposite-modified activated carbon derived from banana peel biomass. DOI: 10.1039/d5ma00168d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of a high-temperature box furnace in the synthesis of silico-sulfate-phosphate glass fertilizers?

- Why is high-temperature calcination necessary for NiFe2O4? Optimize Spinel Formation with Industrial Muffle Furnaces

- Why are muffle furnaces durable under rigorous industrial conditions? Discover Their Robust Design for Longevity

- Why is an industrial high-temperature furnace required for chemical activation? Achieve 700°C Precision for Carbon

- What are the advantages and disadvantages of muffle furnaces? Achieve Contaminant-Free Heating for Sensitive Applications

- What are muffle furnaces and their primary uses? Essential for Contamination-Free Heating

- How is a muffle furnace utilized in ash testing? Achieve Accurate Mineral Analysis for Your Lab

- How do vacuum muffle furnaces combine the benefits of tube and muffle furnaces? Achieve High Throughput with Purity