At their core, muffle furnaces derive their exceptional durability from a specific design philosophy: isolating the heating source from the material being processed. This is achieved through a combination of robust, high-temperature materials and a sealed inner chamber—the "muffle"—that shields internal components from corrosive atmospheres, thermal shock, and direct contact, ensuring long-term operational integrity.

A muffle furnace's durability is not an accident but a direct consequence of its primary function. By creating a contamination-free environment for the sample, its design inherently protects its own critical heating elements and structural materials from the very high-temperature processes it enables.

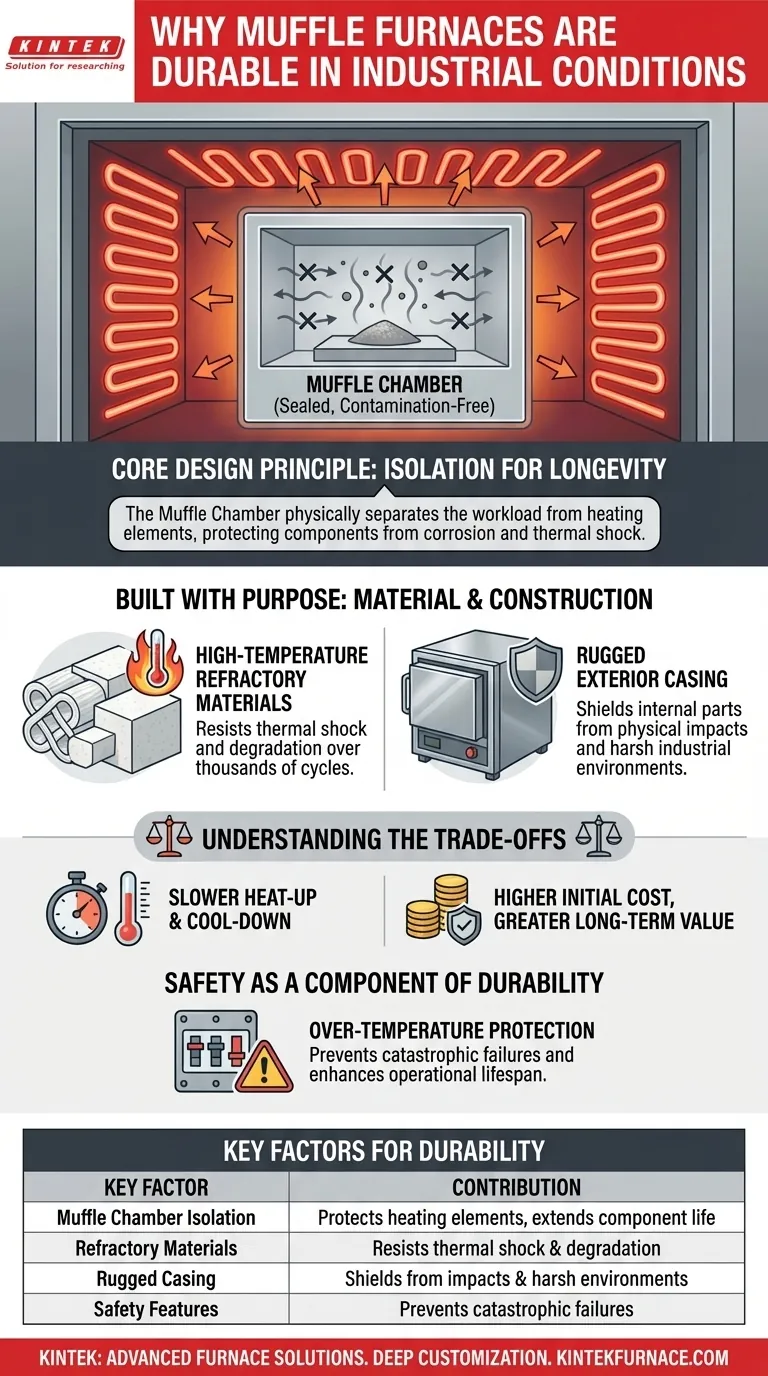

The Core Design Principle: Isolation for Longevity

The defining feature of a muffle furnace is the "muffle" itself—an isolated chamber that separates the workload from the heating elements. This design is the primary source of its durability.

What is the "Muffle"?

The muffle is a sealed inner chamber, typically made of high-temperature ceramic or a metallic alloy. It physically separates the materials you are heating from the combustion byproducts or the raw energy of the heating elements.

This separation prevents chemical reactions between the workload and the furnace's own components, which is a common cause of failure in simpler high-temperature ovens.

Protecting the Heating Elements

Heating elements are the heart of the furnace and are vulnerable to degradation. The muffle acts as a protective barrier, shielding them from vapors, fumes, or particles released from the sample during heating.

This prevents corrosion and burnout, dramatically extending the life of the most critical and expensive components of the furnace.

Ensuring a Controlled, Stable Atmosphere

By isolating the chamber, the furnace can maintain a precise and stable atmosphere, free from contaminants. This process stability also contributes to durability, as it avoids the unpredictable chemical reactions and thermal stresses that can damage internal refractory materials over time.

Built with Purpose: Material and Construction

A muffle furnace is engineered from the ground up to withstand extreme conditions. Its longevity is a direct result of the materials used in its construction.

High-Temperature Refractory Materials

The inner muffle and surrounding insulation are constructed from advanced refractory materials, such as high-purity ceramic fiber or alumina. These materials are chosen for their excellent thermal stability and resistance to thermal shock.

They can endure thousands of cycles of rapid heating and cooling without cracking or degrading, forming the backbone of the furnace's structural integrity.

Rugged Exterior Casing

The internal components are protected by a heavy-gauge steel casing. This rugged exterior shields the delicate insulation and electronics from the physical impacts, spills, and corrosive atmospheres common in industrial environments like metallurgy, glass manufacturing, and aerospace testing labs.

Understanding the Trade-offs

While exceptionally durable, the design of a muffle furnace involves specific trade-offs that are important to understand.

Slower Heat-Up and Cool-Down Times

The same thermal mass and heavy insulation that make the furnace durable also mean it has high thermal inertia. Consequently, muffle furnaces often heat up and cool down more slowly than less-insulated ovens.

Higher Initial Cost

The specialized materials and robust construction required for high performance and durability result in a higher initial investment compared to simpler lab ovens that are not designed for the same level of intensity or process purity.

Maintenance Is Still Required

"Durable" does not mean invincible. Components like door seals, thermocouples (temperature sensors), and eventually the heating elements themselves are consumables. They require periodic inspection and replacement to ensure continued safe and efficient operation.

Safety as a Component of Durability

A truly durable piece of industrial equipment is also a safe one. Muffle furnaces incorporate safety features that protect the unit from self-destruction.

Preventing Catastrophic Failure

Modern furnaces include safety controllers, such as an open circuit safety trigger. If a primary control component fails, this system cuts power to the heating elements, preventing a "run-away" condition.

This over-temperature protection not only ensures user safety but also prevents a thermal event that could permanently damage or destroy the furnace, making it a key feature of its operational lifespan.

Making the Right Choice for Your Application

Understanding these principles helps you align the furnace's strengths with your specific industrial goal.

- If your primary focus is process purity and repeatability: The key takeaway is the isolated muffle design, which guarantees a contaminant-free atmosphere for sensitive materials.

- If your primary focus is long-term reliability in a harsh environment: The combination of robust refractory materials, a rugged steel exterior, and protected heating elements ensures a long service life.

- If your primary focus is operational safety: Integrated features like over-temperature protection are critical, preventing catastrophic failure and preserving the equipment investment.

Ultimately, a muffle furnace is built to last because its design prioritizes process integrity, which inherently creates a more stable and protected system.

Summary Table:

| Key Factor | Contribution to Durability |

|---|---|

| Muffle Chamber Isolation | Protects heating elements from corrosion and extends component life |

| High-Temperature Refractory Materials | Resists thermal shock and degradation over thousands of cycles |

| Rugged Steel Casing | Shields internal parts from physical impacts and harsh environments |

| Safety Features (e.g., Over-Temperature Protection) | Prevents catastrophic failures and enhances operational lifespan |

| Controlled Atmosphere | Reduces chemical reactions and thermal stresses on internal materials |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your lab's efficiency and durability with tailored furnace solutions that ensure long-term reliability and process purity!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity