At its core, a vacuum muffle furnace merges two distinct advantages: the large, efficient processing capacity of a traditional muffle furnace and the controlled atmospheric precision of a tube furnace. This hybrid design solves a common trade-off in high-temperature applications, allowing for both high volume and high purity in a single piece of equipment.

A vacuum muffle furnace resolves the classic laboratory dilemma of choosing between sample volume and atmospheric control. By integrating precise gas handling into a high-capacity chamber, it offers the best of both worlds, enabling high-throughput processing without sacrificing environmental purity.

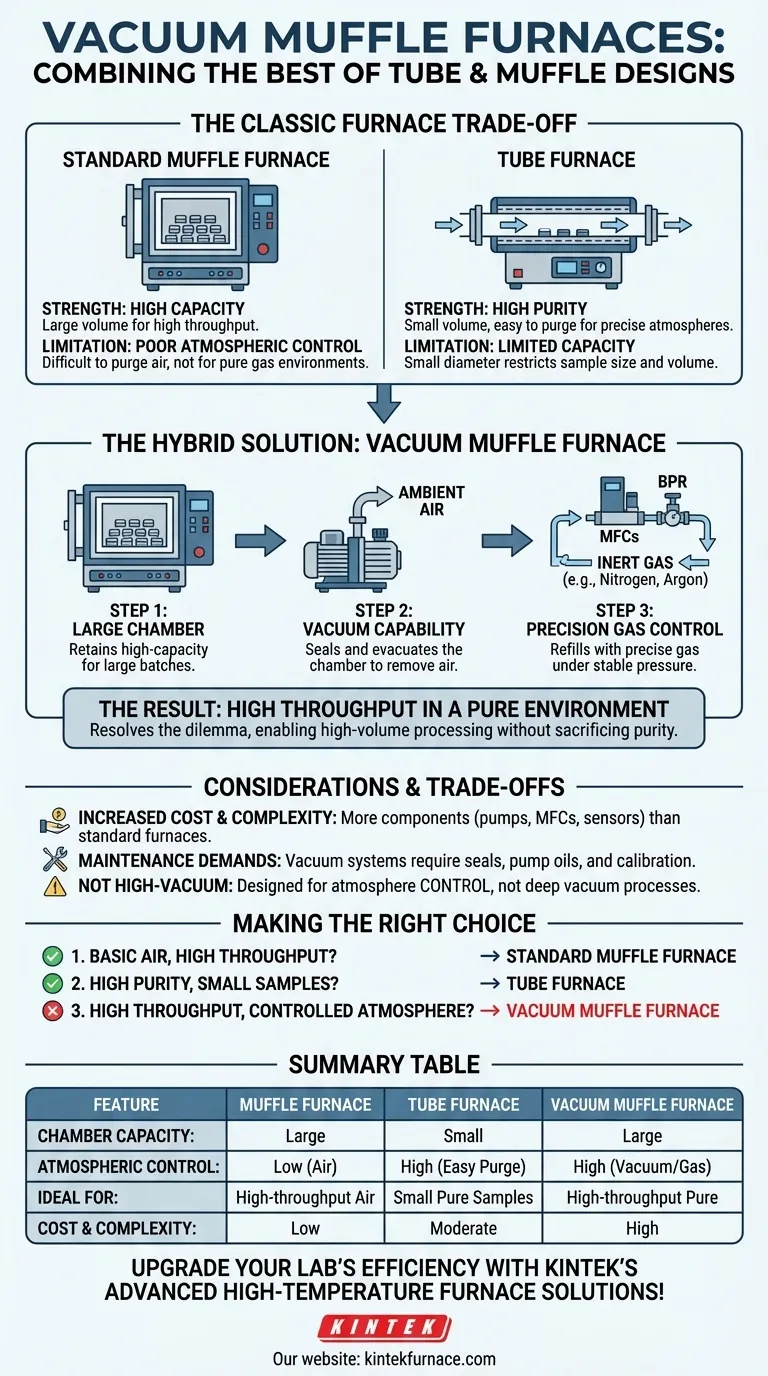

The Classic Furnace Trade-off: Volume vs. Atmosphere

To understand the value of a vacuum muffle furnace, you must first appreciate the limitations of its predecessors. Laboratories have historically had to choose between two fundamentally different designs.

The Strength of the Muffle Furnace: Capacity

A standard muffle furnace features a large, box-shaped chamber. This design is highly efficient for processing large items or many smaller samples simultaneously.

Modern muffle furnaces also provide excellent temperature uniformity and isolate materials from any heating element contaminants, making them a reliable workhorse for general heat-treating and ashing.

The Strength of the Tube Furnace: Purity

A tube furnace uses a narrow, cylindrical chamber. Its small internal volume makes it exceptionally easy to purge ambient air and create a highly pure, controlled gas environment.

This precision is critical for processes where any exposure to oxygen or other atmospheric contaminants would ruin the sample.

The Inherent Compromise

The problem is that each design excels where the other fails. The large chamber of a muffle furnace is difficult to purge of air, making true atmospheric control nearly impossible.

Conversely, the small diameter of a tube furnace severely limits sample size and overall throughput, creating a bottleneck in many workflows.

How Vacuum Muffle Furnaces Bridge the Gap

A vacuum muffle furnace strategically combines technologies to eliminate this compromise. It doesn't just mix features; it integrates them to create a fundamentally more capable system.

Step 1: Retain the High-Capacity Chamber

The design starts with the benefit of the muffle furnace: a large, dimensionally efficient chamber. This preserves the ability to process large batches of samples, maximizing throughput.

Step 2: Add Vacuum Capability

This is the first critical enhancement. By sealing the chamber and adding a vacuum pump, the furnace can actively remove the ambient atmosphere. This initial evacuation is far more effective than simply flooding a standard chamber with inert gas.

Step 3: Integrate Precision Gas Control

After the vacuum has created a clean slate, specialized components take over.

Mass Flow Controllers (MFCs) are used to inject a precise amount of a specific gas (such as nitrogen or argon) back into the chamber.

Back Pressure Regulators (BPRs) work in tandem with the MFCs to maintain a stable, positive pressure inside the chamber, preventing any outside air from leaking in.

The Result: High Throughput in a Pure Environment

This sequence—evacuate, then refill with a controlled gas—effectively imparts the atmospheric purity of a tube furnace onto the high-capacity chamber of a muffle furnace. Labs can now process more samples in less time without compromising on environmental control.

Understanding the Trade-offs and Considerations

While powerful, this technology is not without its own set of considerations. Objectivity requires acknowledging its limitations.

Increased Cost and Complexity

Integrating vacuum pumps, seals, sensors, MFCs, and BPRs makes a vacuum muffle furnace significantly more expensive and complex than either a standard muffle or tube furnace.

Maintenance Demands

Vacuum systems require diligent maintenance. Seals can wear out, pumps require oil changes, and sensors need calibration to ensure the system performs to specification. This represents an ongoing operational commitment.

Not a High-Vacuum System

It is crucial to understand that a vacuum muffle furnace is designed for atmosphere control, not for high-vacuum processes. Its purpose is to purge contaminants and create a specific gas environment, not to sustain the deep vacuum needed for certain materials science applications.

Making the Right Choice for Your Application

The decision to invest in a vacuum muffle furnace should be driven by a clear understanding of your primary process goal.

- If your primary focus is maximum sample throughput with basic air atmosphere heating: A standard muffle furnace is the most direct and cost-effective solution.

- If your primary focus is absolute atmospheric purity on a few small samples: A traditional tube furnace remains an excellent and simple choice for its precise control.

- If your primary focus is high-throughput processing in a controlled inert or reactive gas atmosphere: A vacuum muffle furnace is the ideal technology, justifying its investment through superior efficiency and capability.

By understanding this hybrid approach, you can select equipment that directly aligns with your process goals and avoids unnecessary compromise.

Summary Table:

| Feature | Vacuum Muffle Furnace | Muffle Furnace | Tube Furnace |

|---|---|---|---|

| Chamber Capacity | Large | Large | Small |

| Atmospheric Control | High (via vacuum and gas systems) | Low (basic air) | High (easy to purge) |

| Ideal For | High-throughput with purity | High-throughput in air | Small samples with purity |

| Cost and Complexity | High | Low | Moderate |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for high-throughput, pure processing. Don't compromise—contact us today to discuss how we can enhance your workflow and deliver reliable results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process