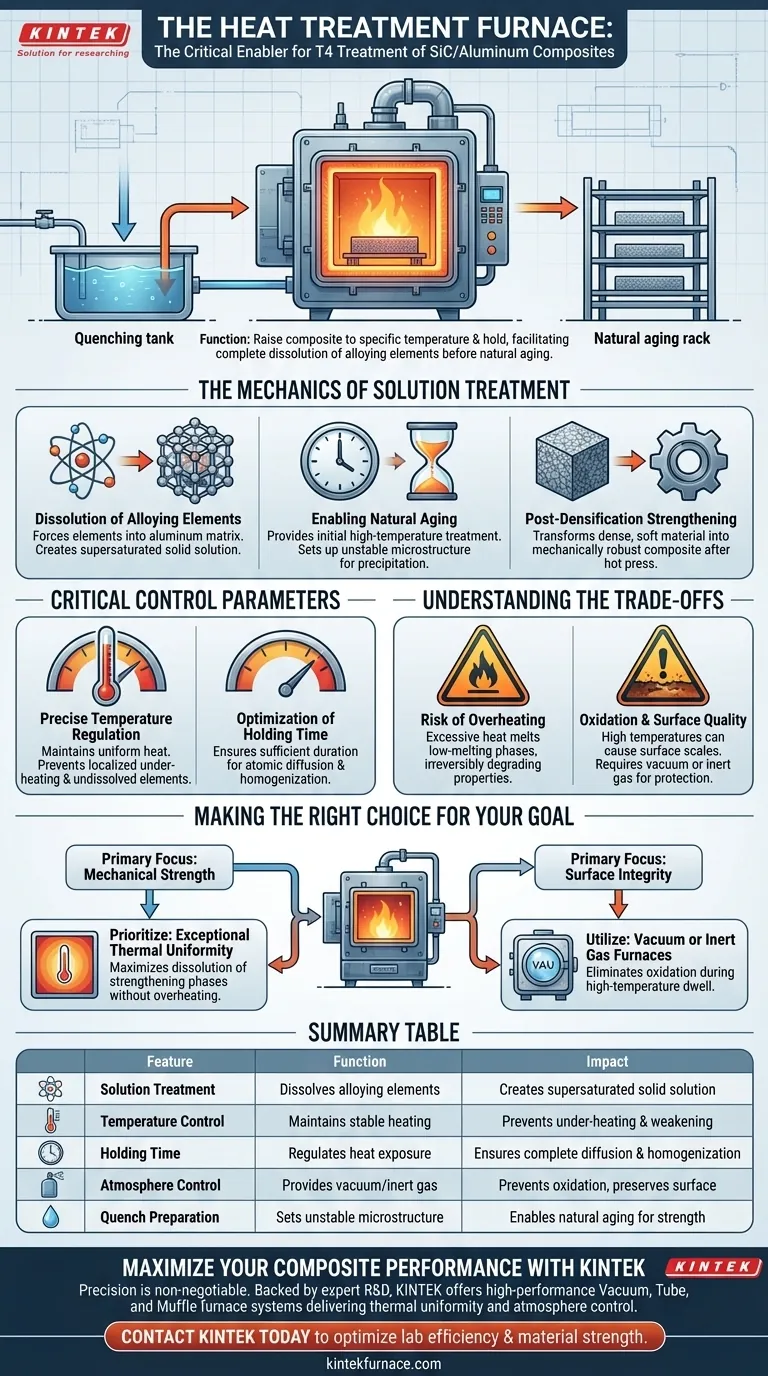

The heat treatment furnace serves as the critical enabler for the T4 temper condition in SiC/Aluminum composites, primarily by facilitating solution treatment. Its function is to raise the composite to a specific temperature and hold it there, ensuring that alloying elements fully dissolve into the aluminum matrix before the material undergoes natural aging.

The furnace's role is to create a homogenous solid solution by dissolving alloying elements under strict temperature control. This prepares the matrix for the subsequent precipitation of strengthening phases during natural aging, which is essential for maximizing the strength of the composite after hot press densification.

The Mechanics of Solution Treatment

Dissolution of Alloying Elements

The fundamental purpose of the furnace during the T4 cycle is to dissolve soluble alloying elements. By applying high heat, the furnace forces these elements to integrate fully into the aluminum matrix. This creates a supersaturated solid solution, which is the prerequisite for any future strengthening.

Enabling Natural Aging

While T4 involves "natural" aging (occurring at room temperature), the process cannot start without the furnace. The furnace provides the initial high-temperature solution treatment that creates the unstable microstructure necessary for aging. Once removed from the furnace and quenched, the material naturally precipitates strengthening phases over time.

Post-Densification Strengthening

The furnace treatment typically follows hot press densification. While the hot press ensures the material is dense and free of voids, the heat treatment furnace is responsible for the metallurgical properties. It transforms a dense but potentially soft material into a mechanically robust composite.

Critical Control Parameters

Precise Temperature Regulation

The furnace must maintain a stable and uniform temperature field throughout the heating zone. This uniformity ensures that the solution treatment is consistent across the entire geometry of the composite part. Precise control prevents localized under-heating, which would leave alloying elements undissolved and weaken the material.

Optimization of Holding Time

The furnace regulates the duration of the heat exposure, known as the holding time. This time must be sufficient to allow atomic diffusion and homogenization of the microstructure. Proper timing ensures the maximum amount of strengthening phases are available for precipitation later.

Understanding the Trade-offs

The Risk of Overheating

While high temperatures are necessary for dissolution, excessive heat can be detrimental. If the furnace exceeds specific limits, it may melt low-melting-point eutectic phases within the matrix. This results in incipient melting, which irreversibly degrades the mechanical properties of the composite.

Oxidation and Surface Quality

At the high temperatures required for solution treatment, aluminum and SiC are prone to oxidation. Standard furnaces may allow surface scales to form, compromising the part's integrity. Vacuum or atmosphere-controlled furnaces are often required to evacuate oxygen or backfill with inert gas, preventing surface degradation.

Making the Right Choice for Your Goal

To achieve the best results with T4 treatment of SiC/Aluminum composites, align your furnace capabilities with your specific material requirements:

- If your primary focus is mechanical strength: Prioritize a furnace with exceptional thermal uniformity to ensure maximum dissolution of strengthening phases without overheating.

- If your primary focus is surface integrity: Utilize a vacuum furnace or one with inert gas capabilities (like argon) to eliminate oxidation during the high-temperature dwell.

The heat treatment furnace acts as the bridge between a raw densified part and a high-performance structural component.

Summary Table:

| Feature | Function in T4 Treatment | Impact on SiC/Al Composite |

|---|---|---|

| Solution Treatment | Dissolves alloying elements into the matrix | Creates a supersaturated solid solution |

| Temperature Control | Maintains stable and uniform heating | Prevents under-heating and localized weakening |

| Holding Time | Regulates duration of heat exposure | Ensures complete atomic diffusion and homogenization |

| Atmosphere Control | Provides vacuum or inert gas (Argon) | Prevents oxidation and preserves surface integrity |

| Quench Preparation | Sets the unstable microstructure | Enables natural aging for post-densification strength |

Maximize Your Composite Performance with KINTEK

Precision is non-negotiable when managing the T4 treatment of SiC/Aluminum composites. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vacuum, Tube, and Muffle furnace systems specifically designed to deliver the thermal uniformity and atmosphere control required for advanced material metallurgy.

Whether you need to eliminate oxidation or ensure perfect solution treatment, our customizable laboratory furnaces provide the reliability your research and production demand. Contact KINTEK today to discover how our high-temperature solutions can optimize your lab's efficiency and material strength.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key steps in vacuum brazing? Master the 5-Step Process for Strong, Clean Joints

- What types of heating elements are used in laboratory vacuum furnaces and how do they function? Optimize Your High-Temp Processes

- How does a retort furnace differ from a vacuum furnace? Choose the Right Heat Treatment for Your Materials

- How are vacuum furnaces applied in the semiconductor industry? Essential for High-Purity Chip Manufacturing

- What role does a vacuum sintering furnace play in fine ceramic component production? Achieve High-Purity, Dense Ceramics

- What are some common applications of vacuum chamber furnaces? Unlock High-Purity Material Transformations

- What is the function of a non-consumable vacuum arc furnace? Achieve Purity in FeSiBPCCuNb Alloy Synthesis

- How does a vacuum furnace improve smelting quality? Achieve Purer, Stronger Metals for Your Applications