The non-consumable vacuum arc furnace functions as the critical melting environment where raw elements are synthesized into a chemically uniform FeSiBPCCuNb alloy ingot. By utilizing a tungsten electrode to generate a stable electric arc, the furnace provides the extreme local temperatures necessary to melt high-melting-point components while maintaining a high-vacuum atmosphere to prevent material degradation.

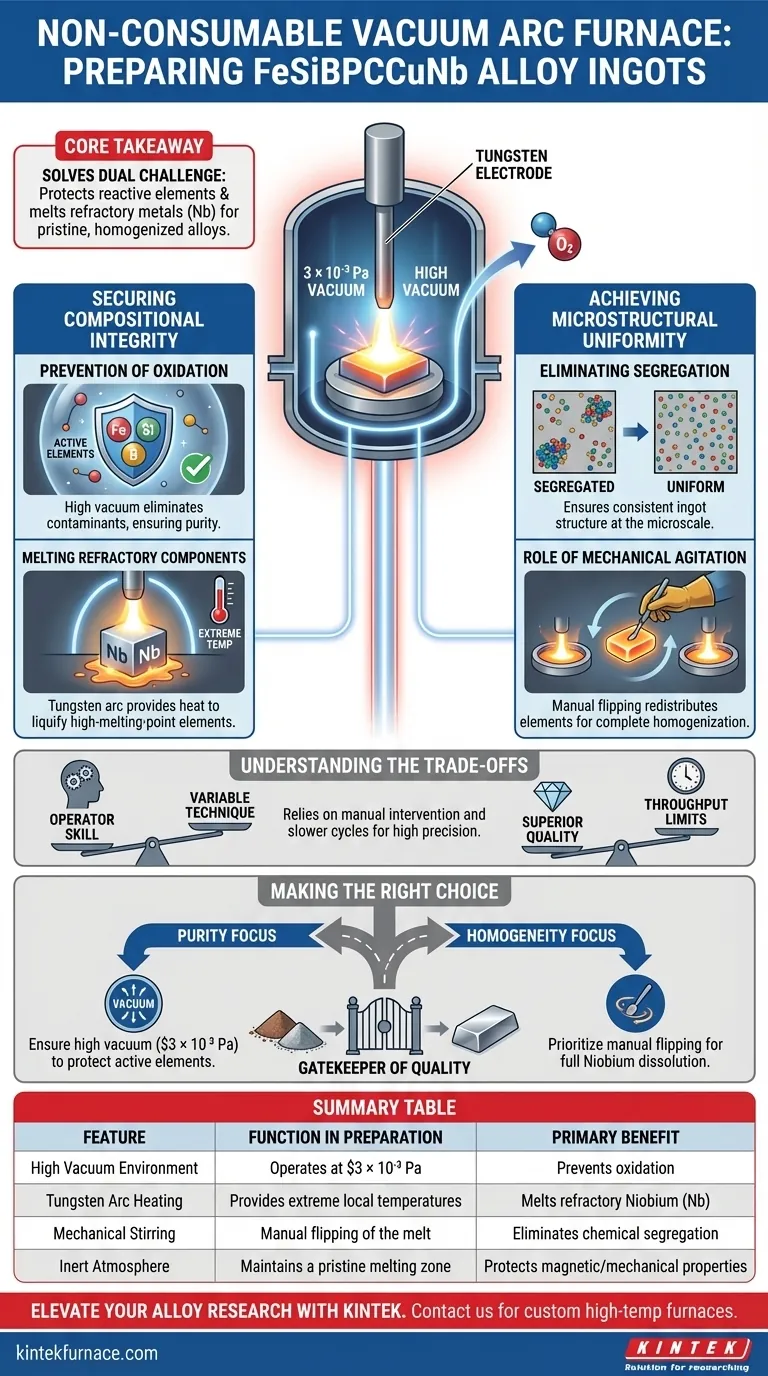

Core Takeaway The furnace solves the dual challenge of protecting reactive elements from oxidation and melting refractory metals like Niobium (Nb). Its primary value lies in creating a pristine, high-vacuum environment ($3 \times 10^{-3}$ Pa) that facilitates the complete homogenization of complex, multi-component alloys.

Securing Compositional Integrity

Prevention of Elemental Oxidation

The preparation of FeSiBPCCuNb involves "active" elements that react aggressively with oxygen.

The furnace operates under a high vacuum (typically $3 \times 10^{-3}$ Pa) to eliminate atmospheric contaminants. This effectively prevents the oxidation of these sensitive components, ensuring the final alloy retains its intended purity and magnetic or mechanical properties.

Melting Refractory Components

Elements within this specific alloy matrix, particularly Niobium (Nb), possess very high melting points.

Standard heating methods may fail to fully liquify these refractory elements before other components vaporize. The vacuum arc provides extremely high local temperatures, ensuring even the most heat-resistant elements are completely melted and integrated into the matrix.

Achieving Microstructural Uniformity

Eliminating Segregation

In multi-component alloys like FeSiBPCCuNb, chemical segregation—where elements clump together rather than mixing—is a significant risk.

The furnace ensures high chemical composition uniformity at the microscale. This results in a consistent ingot structure, which is a prerequisite for reliable performance in subsequent processing steps.

The Role of Mechanical Agitation

Uniformity is not achieved solely through heat; it requires physical manipulation of the melt.

The process involves manual stirring functions, such as flipping the alloy ingot with a stirring spoon between melts. This mechanical mixing is vital for redistributing elements that may have settled due to density differences.

Understanding the Trade-offs

Reliance on Operator Skill

Unlike fully automated induction systems, this process often relies on manual intervention, such as the flipping of the ingot.

This introduces a variable of human technique. The uniformity of the final ingot depends heavily on the operator's diligence in repeating the melting and flipping process sufficient times.

Throughput Limitations

The requirement for high vacuum pumping and repeated manual flipping cycles extends the cycle time for each ingot.

While this method produces superior quality for research or high-precision applications, it is generally slower than continuous casting methods used for lower-grade commercial alloys.

Making the Right Choice for Your Goal

The non-consumable vacuum arc furnace is a precision tool, not a volume tool. When preparing FeSiBPCCuNb, your operational priorities dictate how you utilize the equipment.

- If your primary focus is Purity: Ensure the vacuum level reaches at least $3 \times 10^{-3}$ Pa before initiating the arc to protect active elements.

- If your primary focus is Homogeneity: Prioritize the manual stirring process, flipping and re-melting the ingot multiple times to ensure Niobium is fully dissolved.

This furnace acts as the gatekeeper of quality, converting a mix of raw powders and granules into a singular, high-performance alloy worthy of further study.

Summary Table:

| Feature | Function in FeSiBPCCuNb Preparation | Primary Benefit |

|---|---|---|

| High Vacuum Environment | Operates at $3 \times 10^{-3}$ Pa to remove oxygen | Prevents oxidation of active elements |

| Tungsten Arc Heating | Provides extreme local temperatures | Completely melts refractory Niobium (Nb) |

| Mechanical Stirring | Manual flipping/stirring of the melt | Eliminates chemical segregation |

| Inert Atmosphere | Maintains a pristine melting zone | Protects magnetic and mechanical properties |

Elevate Your Alloy Research with KINTEK

Precision in FeSiBPCCuNb synthesis requires equipment that can handle extreme temperatures while maintaining absolute purity. Backed by expert R&D and precision manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside other specialized lab high-temp furnaces—all fully customizable to meet your unique material specifications.

Don't let oxidation or segregation compromise your results. Let our technical team help you configure the perfect furnace for your refractory alloy needs. Contact KINTEK today to discuss your custom solution!

Visual Guide

References

- Xi Huang, Wenlong Zhu. Effects of Annealing Time on the Structure Characteristics and Magnetic Properties of FeSiBPCCuNb Amorphous Ribbons. DOI: 10.3390/coatings15010050

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does the vacuum pumping system in a vertical vacuum furnace operate? Learn the Multi-Stage Process for Precision

- Why is HIP post-treatment required for ceramics? Achieve Zero Porosity and Maximum Optical Clarity

- How is thermocouple wastage reduced in high temperature vacuum furnaces? Extend Lifespan with Hybrid Systems

- What technical advantages do electric furnace systems offer for copper slag impoverishment? Maximize Your Metal Recovery

- What is the primary purpose of using a vacuum oven for PLA and EG pretreatment? Prevent Hydrolytic Degradation

- How does vacuum hardening affect the hardness and surface layer of high-alloy tool steel? Boost Performance with Superior Heat Treatment

- What is the function of a vacuum brazing furnace? Achieve Clean, Strong Metal Joints in High-Vacuum

- What are the key specifications of vacuum carburizing furnaces? Optimize Your Heat Treatment Process